You need medical devices to work safely and correctly every time. Thermal management helps keep these devices working well. If heat builds up, the device might stop working right. It may not last as long. It can even become unsafe. The table below shows some main effects:

|

Consequence |

Impact on Medical Devices |

|---|---|

|

Component Failure |

Causes device problems and can be dangerous |

|

Reduced Device Lifespan |

Makes medical devices wear out faster |

|

Safety Hazards |

Puts patients at risk in important situations |

Smaller tools and imaging machines have more trouble with heat. You must fix these problems to keep care safe and helpful.

Good thermal management helps keep medical devices safe. It stops them from getting too hot. Overheating can make devices break and cause danger.

Keeping the right temperature helps devices last longer. This means less money spent on fixing them. Devices will work when people need them.

Patients are safer when thermal management is done right. It stops people from getting hurt. It also helps devices give correct results for treatment.

Adding thermal management early in design helps devices work better. Devices can be made smaller and quieter. They will also follow safety rules.

Engineers, designers, and medical experts should work together. This teamwork makes thermal management better. Devices will be safer and work well.

You want your medical devices to work for a long time. Good thermal management helps make this happen. When you control heat, you stop overheating. Devices work better and do not break as much. This means fewer sudden problems and less money spent on repairs. Here are some ways thermal management helps devices last:

Keeping temperatures steady helps medical equipment last longer.

It lowers the chance of device failures that can stop patient care.

You spend less money because you do not need as many repairs or new devices.

Devices become more reliable, so doctors and nurses can trust them.

Using the right thermal methods keeps your equipment safe and strong for many years.

Patient safety depends on how well you control temperature in medical devices. If you do not manage heat, patients can be in danger. The table below shows what happens when temperature is not controlled well:

|

Finding |

Description |

|---|---|

|

Temperature Monitoring |

Only 51.8% of patients had two or fewer temperatures checked during care. |

|

Active Warming Intervention |

68.5% of patients who got warming did not have their temperature checked. |

|

Need for Change |

Hospitals need better ways to check temperatures to keep patients safe. |

Keeping temperatures steady helps patients heal faster. Good temperature control helps people sleep better, which helps them get well and keeps their bodies strong. If it gets too cold, breathing and joint pain can get worse, especially for older people. High heat can cause dehydration and make people feel bad. You also stop infections by controlling humidity and stopping germs from growing. Good thermal management keeps patients safe from these problems.

You must follow strict rules when making medical devices. International standards say you have to control heat and keep devices safe. Here are some important rules:

Devices need at least an IP rating of X4 to keep out dust and water during cleaning.

You must meet USP Class ratings for devices used with things people swallow.

ISO 10993 is needed for devices that touch patients.

Thermal solutions should make it easy to fix and replace parts.

Your design must focus on safety and reliability, meeting higher standards than regular electronics.

If you follow these rules, your devices will be safe and ready to use in hospitals and clinics. You also avoid problems with checks and approvals.

If you do not use thermal management, big problems can happen. Heat can break equipment. It can cause mistakes. It can also put patients in danger. Here are the main risks you should know.

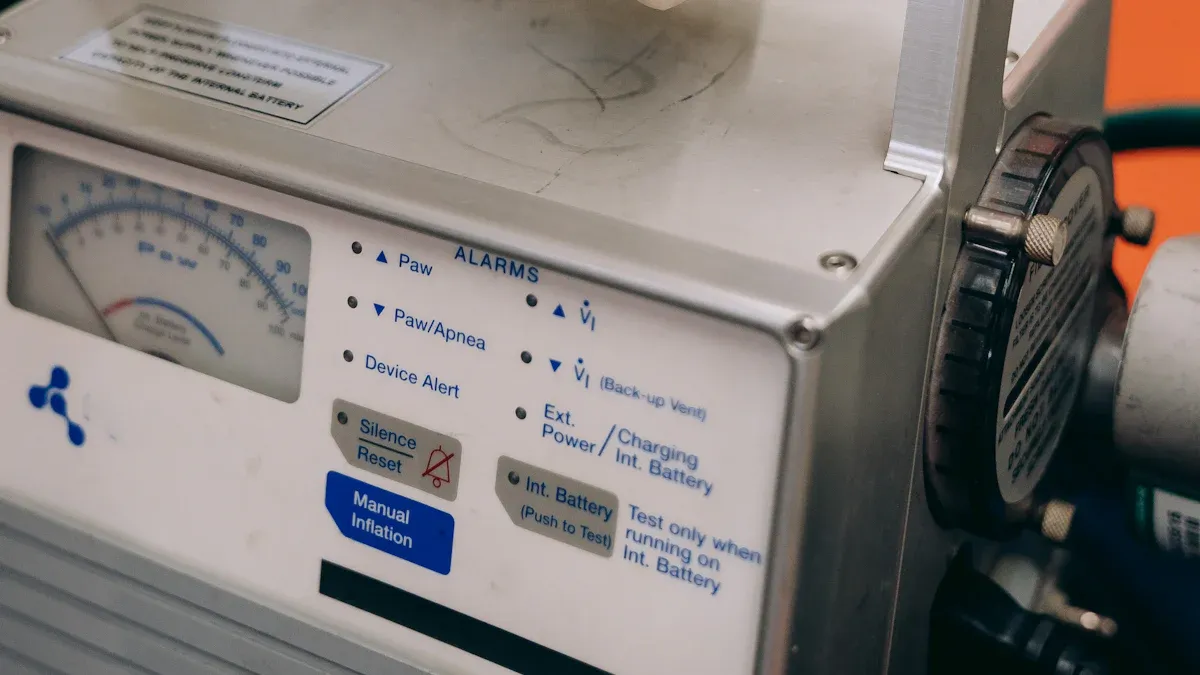

When a device gets too hot, it might stop working. Overheating is a top reason for device failure. Some medical devices have more trouble with heat. These are:

MRI machines

Ventilators

Surgical tools

If these devices get too hot, you might see:

Shorter device life

System errors

Parts breaking down

You must keep these devices cool so they work when needed. MRI machines make a lot of heat during scans. If you do not control the heat, the machine can turn off or give wrong results. Ventilators run for a long time. If they get too hot, they can stop and put patients in danger. Surgical tools need safe temperatures to protect tissue.

Tip: Always check cooling systems before using your devices. This easy step can stop sudden problems.

Heat does not just hurt the device. It can also mess up the data you get. Many medical devices need steady temperatures for correct readings. If the temperature changes a lot, you may get wrong numbers or signals.

Here is how temperature changes affect accuracy:

|

Temperature Condition |

Impact on Diagnostic Accuracy |

|---|---|

|

Stable (within range) |

Accurate, reliable, and repeatable results |

|

Fluctuating or unstable |

Signal drift, unreliable measurements, possible false readings |

|

Extreme or uncontrolled |

Device may lose calibration, leading to incorrect diagnoses |

Even small temperature changes can make you lose trust in your device. For example, a blood analyzer can show a wrong result if it gets too hot. This could lead to the wrong care for a patient.

Some devices use materials that change with heat. If you do not control the temperature, these materials can give bad results. You need steady temperatures to make sure your tests are right.

Bad thermal management can hurt patients and staff. Devices that get too hot can burn skin or harm tissue. Some medical uses need very careful temperature control to keep people safe.

|

Medical Application |

Temperature Requirement |

Notes |

|---|---|---|

|

X-ray systems |

20°C to 25°C |

Needs a controlled room for calibration and quality control |

|

Ultrasound probes |

20°C to 100°C |

Must monitor and control to prevent overheating |

|

MRI, CT, PET |

N/A |

Generates heat; needs strong cooling systems |

|

Laser procedures |

Near 37°C |

Must cool tissue to avoid burns or thermal damage |

If you do not keep the right temperature, you could cause burns, tissue damage, or even fires. For example, during laser surgery, you must keep the area cool to protect the skin. In imaging rooms, you need to control the air so machines work safely and give clear pictures.

Note: Always follow the temperature rules for each device. This helps stop accidents and keeps patients safe.

Thermal management is not just for making devices last longer. It also keeps data correct and patients safe. When you control heat, you protect everyone who uses medical technology.

You should think about thermal management right from the start. Planning early helps you find heat problems before they get worse. If you add thermal needs in your first design steps, you get many good things. These include less noise, smaller devices, longer part life, and better infection control. The table below shows some clear benefits of planning early:

|

Measurable Benefits |

|---|

|

Lower noise levels |

|

Smaller package sizes or weights |

|

Reduced healthcare associated infection risks |

|

Extended duty cycles and component lives |

|

Improved isothermality levels to meet precise instrument requirements |

Medical devices are getting smaller all the time. You need to make sure small size does not hurt how well they work. In wearable technology, engineers use special materials and new ways to cool. Fans and heat sinks are too big for tiny spaces. Instead, passive heat spreaders and other materials move heat away from important parts. These choices help keep devices safe and comfortable for people.

Tip: Always pick materials and designs that help heat move away from the device’s center.

You can use smart tools to test your ideas before building the real thing. Simulation tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) show how heat moves inside your device. The table below explains how these tools help:

|

Simulation Tool |

Application in Thermal Performance |

|---|---|

|

Finite Element Analysis (FEA) |

Assesses how temperature changes affect device functionality |

|

Computational Fluid Dynamics (CFD) |

Analyzes fluid dynamics relevant to thermal performance in devices interacting with bodily fluids |

Testing with these tools lets you fix problems early and save money.

You get better results when engineers, designers, and medical experts work together. Each person has a different skill to share. When you work as a team, you find better ways to control heat and keep devices safe. Many companies, like Shenzhen Enna Electronic Technology Co., Ltd., offer advanced thermal management solutions. This company is known for its technical skills, many products, and focus on quality. They have important certifications and give expert advice and customer service. Working with a trusted partner helps you make safer and more reliable medical devices.

You need to focus on thermal control at every step. If you do not, your device might break. It may not work as well. People could even get hurt, as the table shows:

|

Risk Type |

Description |

|---|---|

|

Device Failure |

Overheating can make devices stop working. |

|

Diminished Effectiveness |

Bad temperature control can make treatment worse. |

|

Safety Risks |

Poor thermal control can hurt people. |

To keep devices safe, use good methods like thermal vias and heat sinks. Test your devices in real situations. Try new cooling ideas and watch for new trends in the field.

If you want to know more, you can:

Read guides about better cooling.

Learn how to control temperature for safety.

Keep up with new thermal management technology.

Thermal management is about controlling heat inside medical devices. You use cooling systems and heat sinks. Special materials help keep devices safe. These tools make sure devices work well.

Good thermal management stops devices from getting too hot. This helps devices last longer. It also keeps patients safe from burns or injuries.

You can use simulation tools like FEA and CFD. These tools show how heat moves inside your device. You find problems early and fix them before building.

Pick a company with strong technical skills and fast service. Shenzhen Enna Electronic Technology Co., Ltd. gives high-precision cooling solutions. They deliver samples quickly and have important certifications.

Yes. Good thermal management keeps devices at safe temperatures. You lower the risk of burns, data mistakes, and device failures. This helps protect patients and staff.

By continuing to use the site you agree to our privacy policy Terms and Conditions.