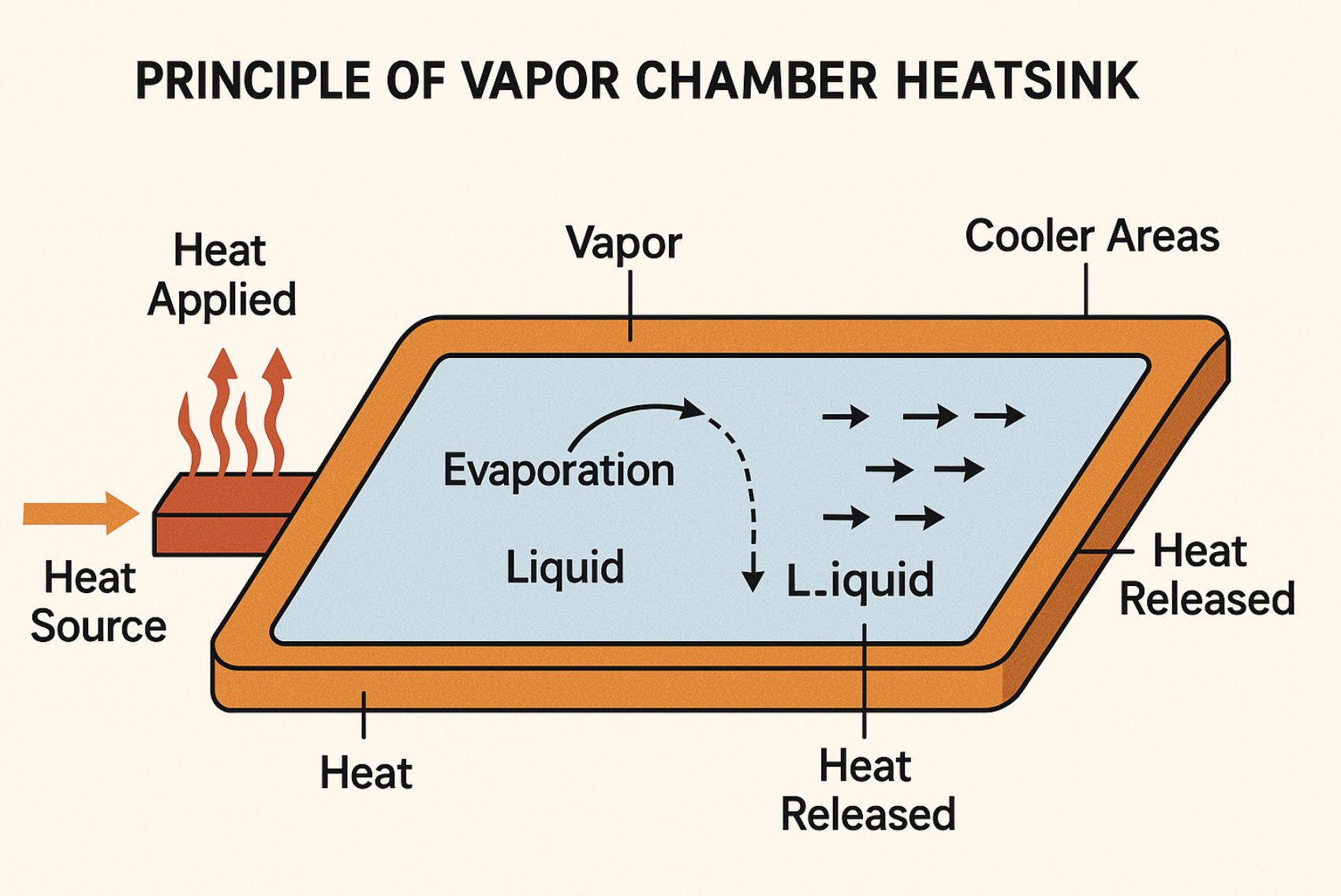

Principle of vapor chamber heatsink

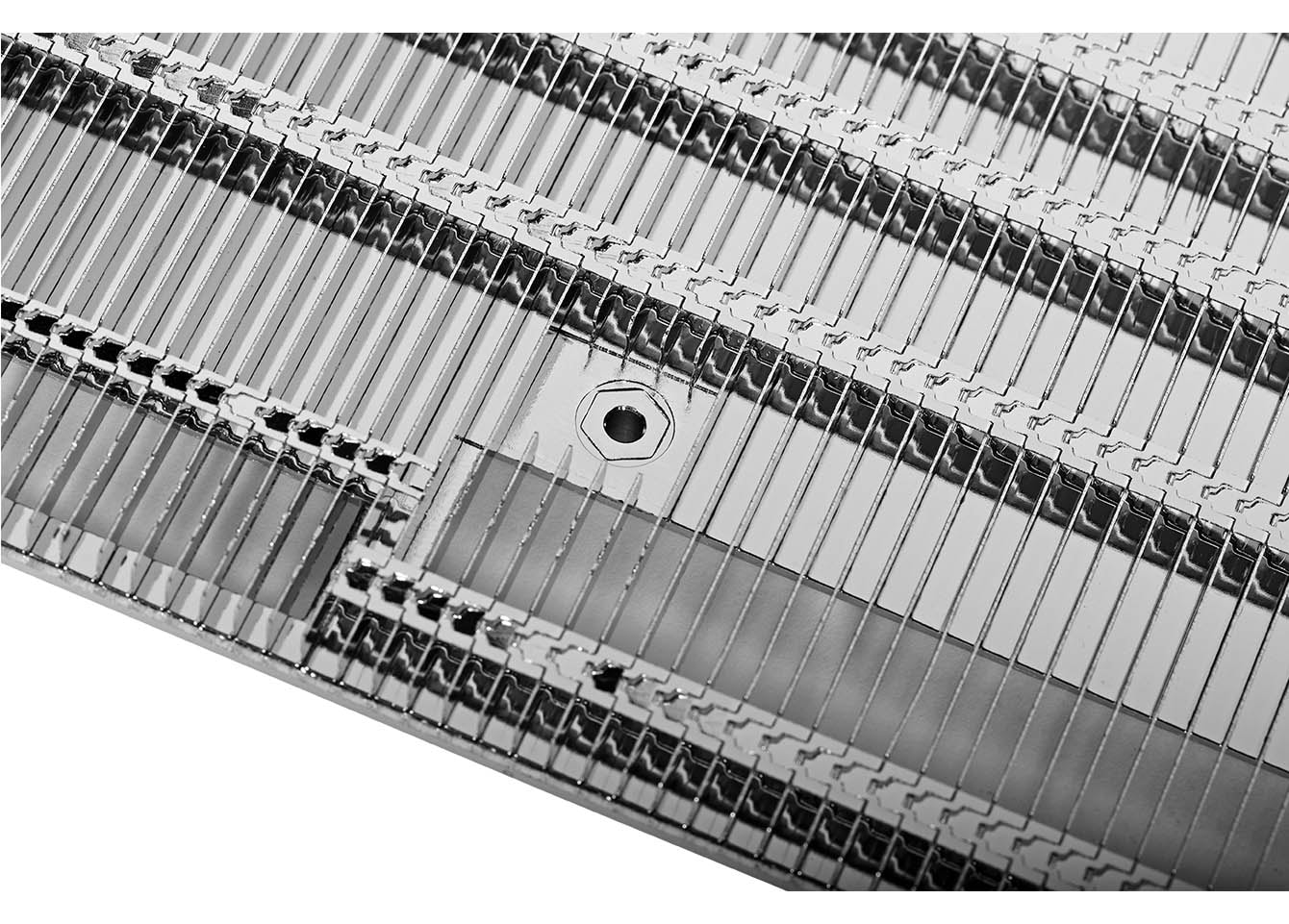

When heat is applied to one area of the vapor chamber, the liquid inside evaporates due to the increased temperature. The vapor then travels to cooler areas within the chamber, where it condenses back into liquid form, releasing the absorbed heat in the process. This cycle continues as long as there is a temperature difference across the vapor chamber, allowing for rapid and uniform heat distribution throughout the chamber.

The key innovation of vapor chamber heatsinks lies in their ability to effectively spread heat over a larger surface area compared to traditional heatsink designs. By utilizing the phase-change properties of the enclosed liquid, vapor chamber heatsinks can transport heat more efficiently, resulting in lower operating temperatures for electronic components.

Furthermore, vapor chamber heatsinks offer greater flexibility in design and integration due to their thin and flat profile, making them suitable for use in compact electronic devices where space is limited. Additionally, advancements in manufacturing techniques have led to the development of vapor chamber heatsinks with customized shapes and sizes, allowing for better compatibility with various hardware configurations and form factors.

vapor chamber heatsinks represent a significant innovation in thermal management technology, offering improved heat dissipation performance, versatility in design, and compatibility with modern electronic devices. Their ability to efficiently transfer heat makes them a preferred choice for applications requiring high-performance cooling solutions.

Why Choose Vapor Chamber Heatsinks?

Ennergroup is a company specializing in the design and manufacture of high-performance vapor chamber heat sinks. Vapor chamber technology offers exceptional thermal conductivity and uniform heat distribution, making it the ideal solution for high-performance applications, such as CPUs, GPUs, and power modules, where efficient cooling is critical to maintaining performance and preventing overheating. These heat sinks are particularly effective in compact systems with stringent space and heat dissipation requirements.

Vapor chambers provide fast heat transfer rates and improved thermal spreading, resulting in better cooling efficiency. The ability to distribute heat evenly across a large surface area ensures the longevity and optimal performance of sensitive electronics. These heatsinks are perfect for applications that require passive cooling without the need for active components, such as fans or pumps.

Ennergroup: Your Vapor Chamber Heatsinks Manufacturer

At Ennergroup, we specialize in the design and manufacture of high-performance vapor chamber heat sinks. Our vapor chambers are engineered to provide superior heat dissipation and optimal thermal management for high-powered electronics. We utilize advanced materials and precision manufacturing techniques to ensure uniform heat distribution and reliable performance. Whether you need standard or custom solutions, we offer efficient thermal management for industries including electronics, telecommunications, automotive, and industrial systems.

-

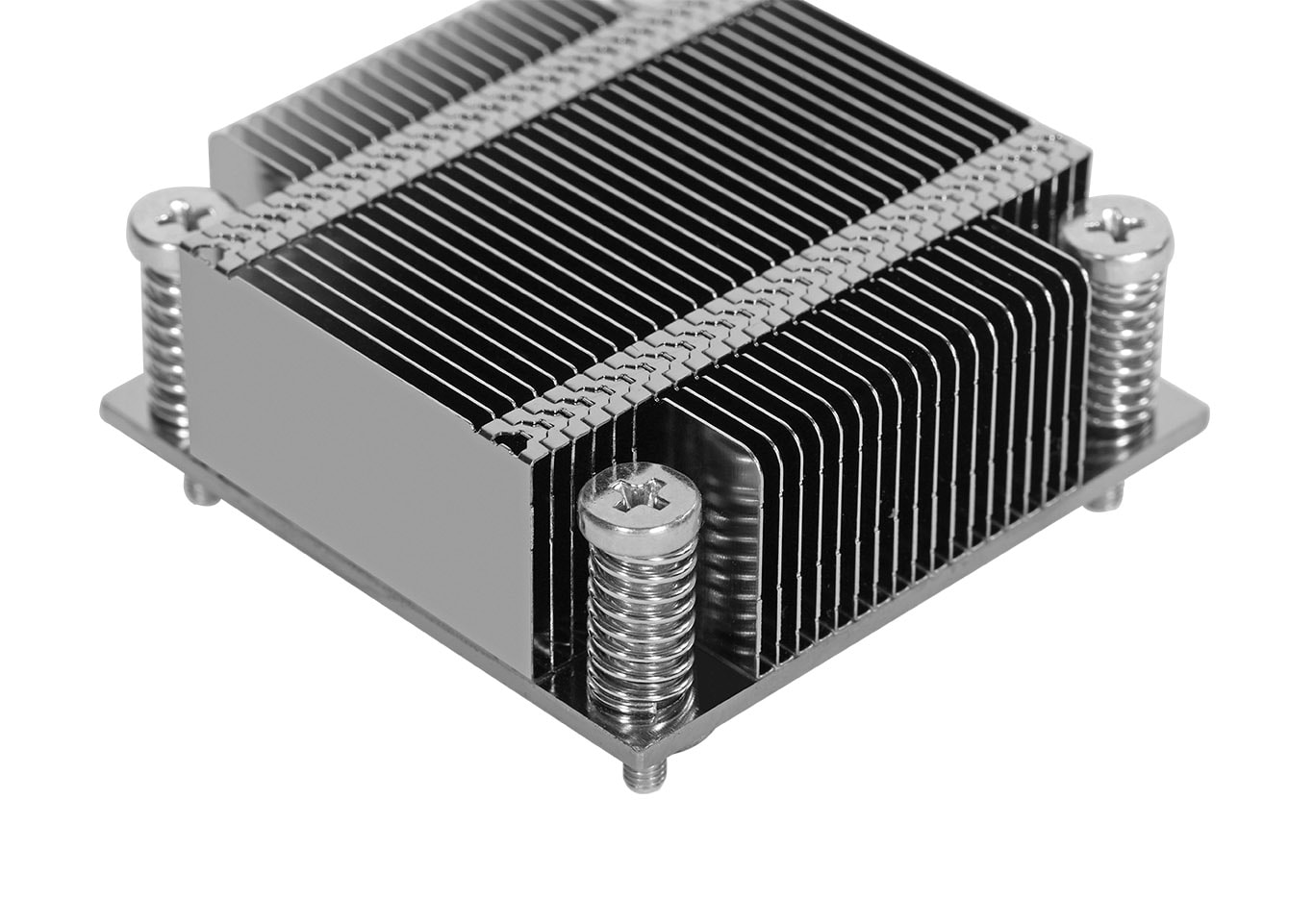

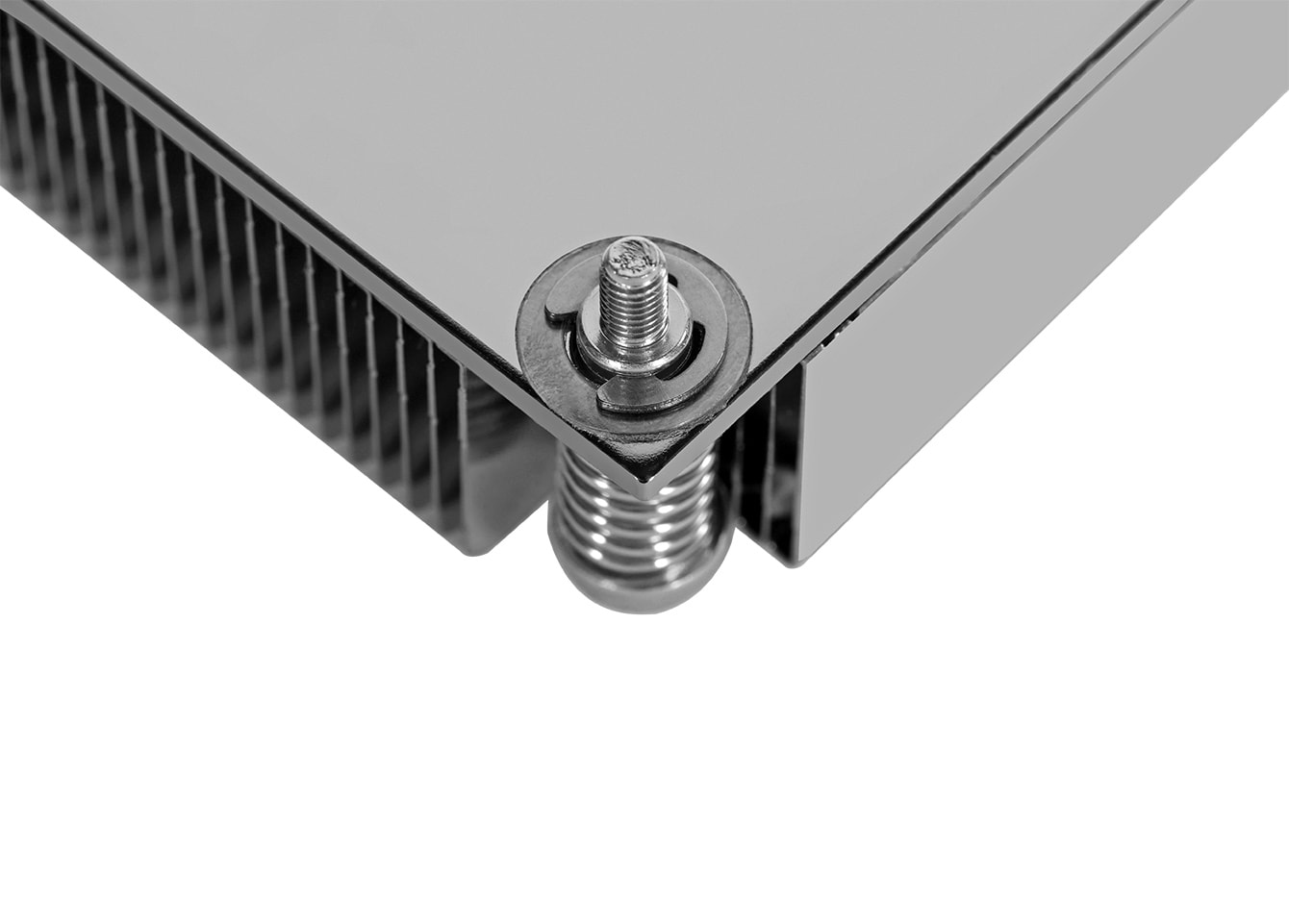

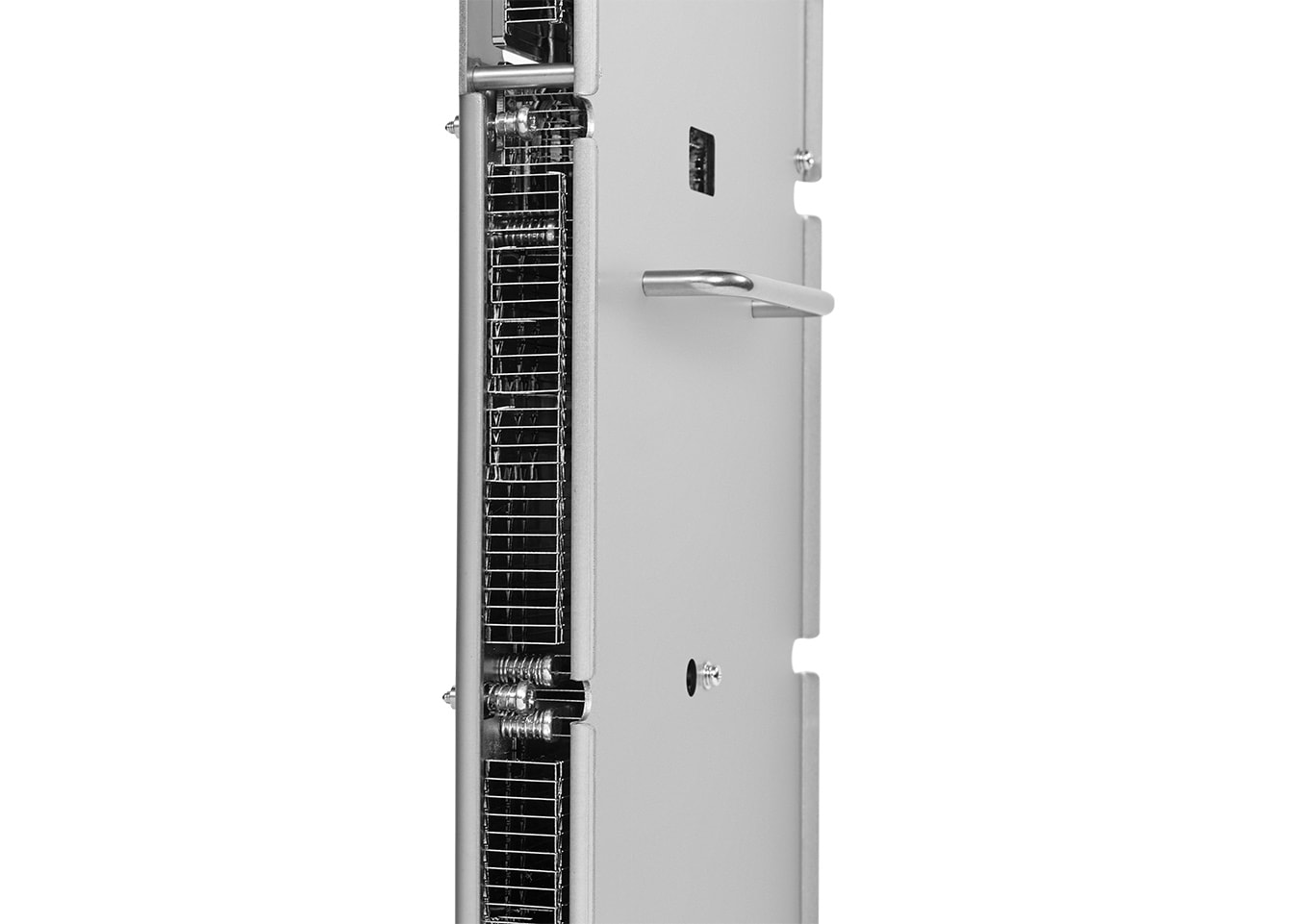

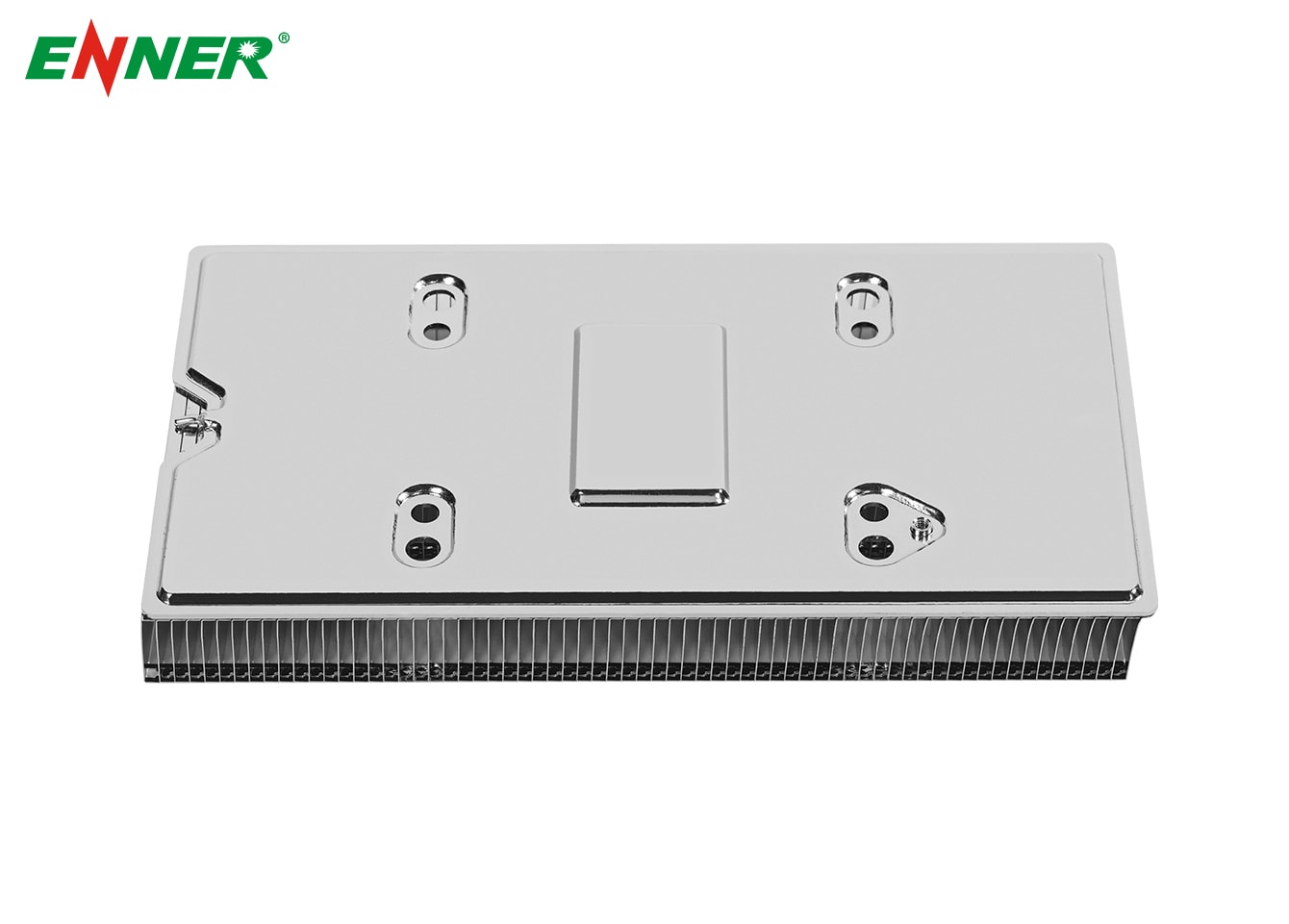

Vapor Chamber Heat Sink For Premium Brewer

This Vapor Chamber Heat Sink for Premium Brewer is engineered for superior thermal performance, providing efficient heat dissipation with cutting-edge vapor chamber technology. Ideal for high-power applications, it features a compact, space-efficient design that optimizes airflow with precision-engineered fins. Built with high-quality materials, it ensures reliable, long-lasting thermal management, enhancing stability and performance. The sturdy mounting structure facilitates easy installation, making it an effective solution for maintaining consistent temperature control and optimal operation of premium brewing equipment.INQUIRE NOW -

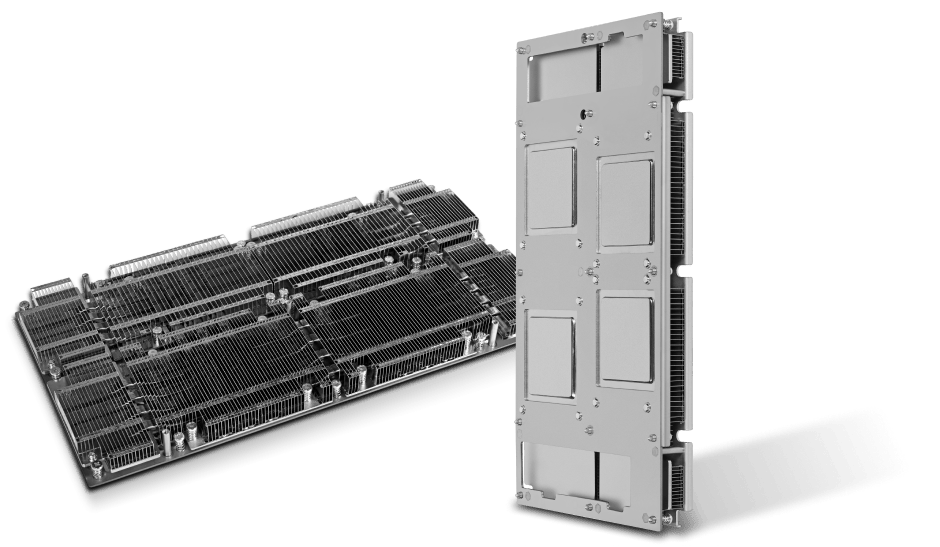

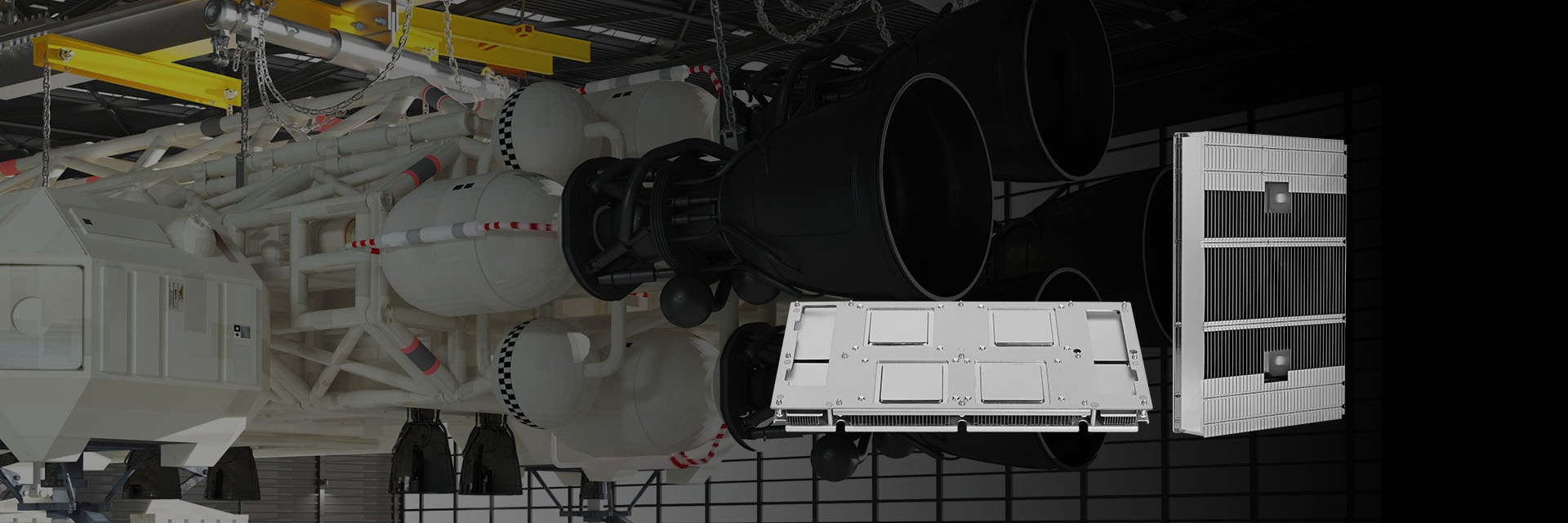

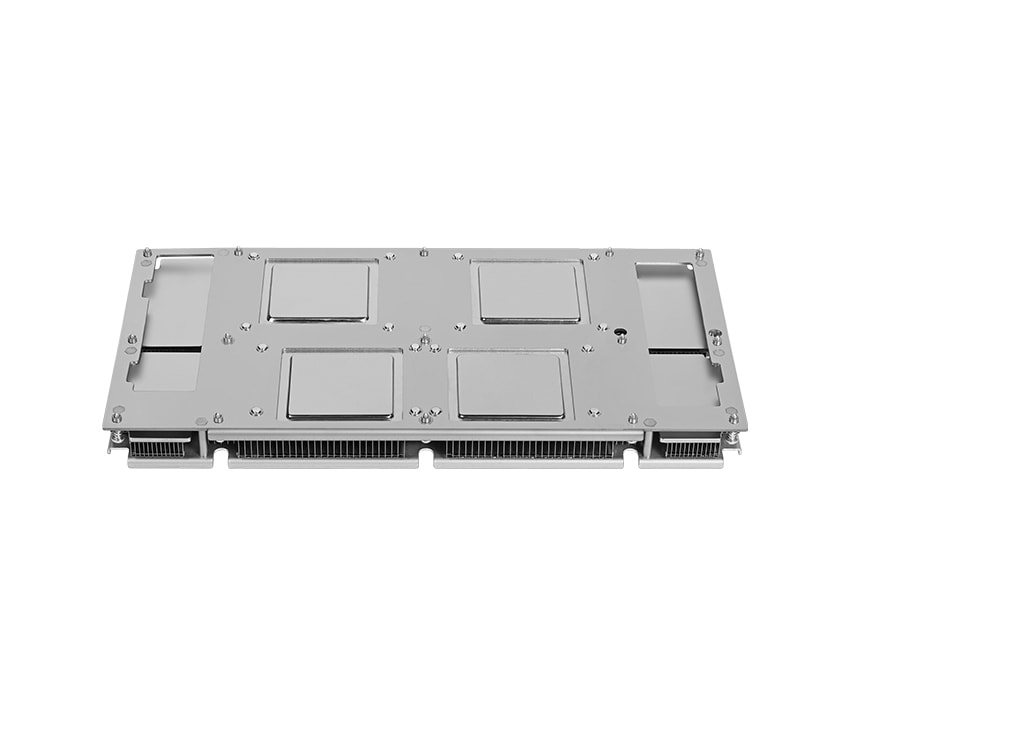

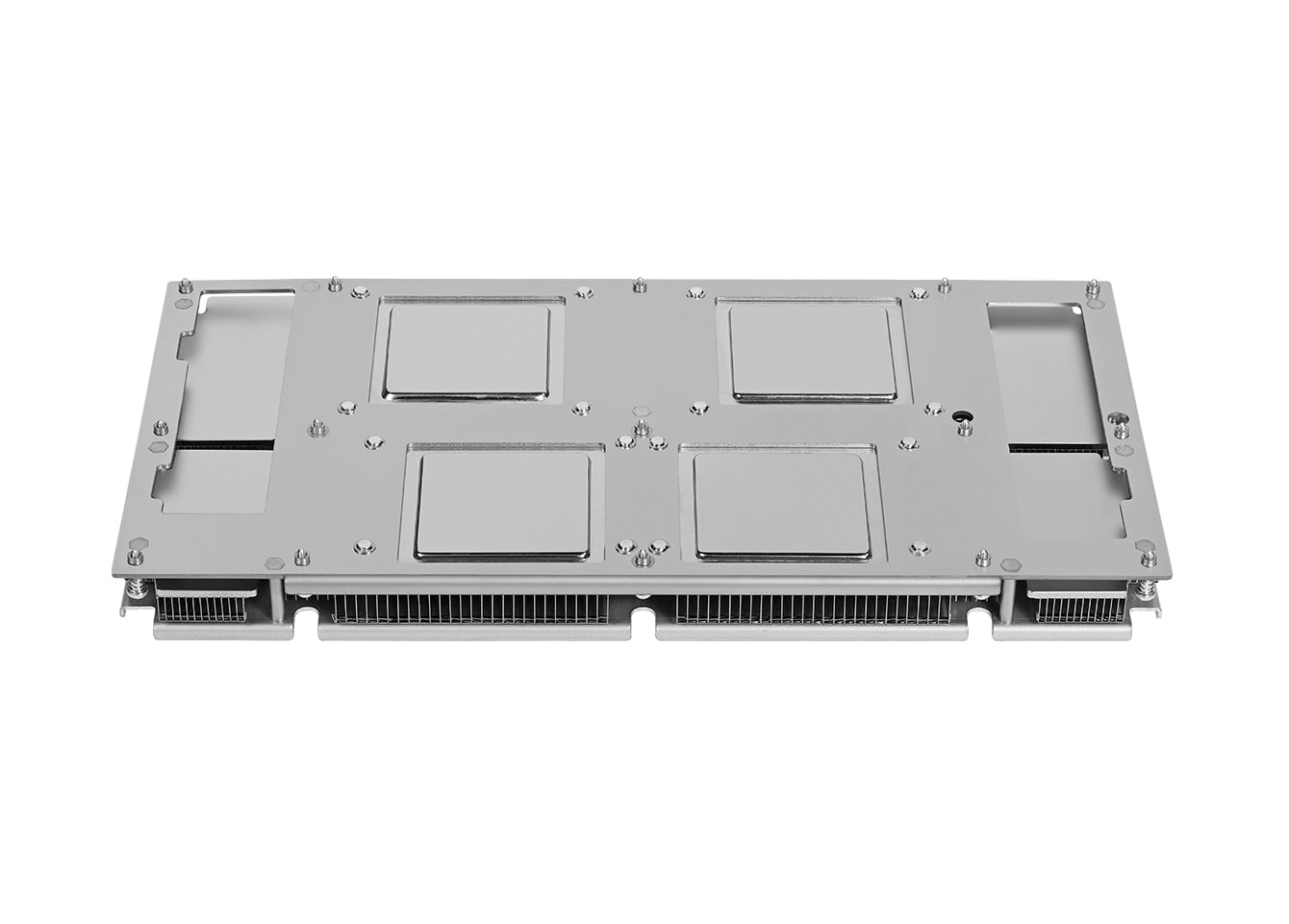

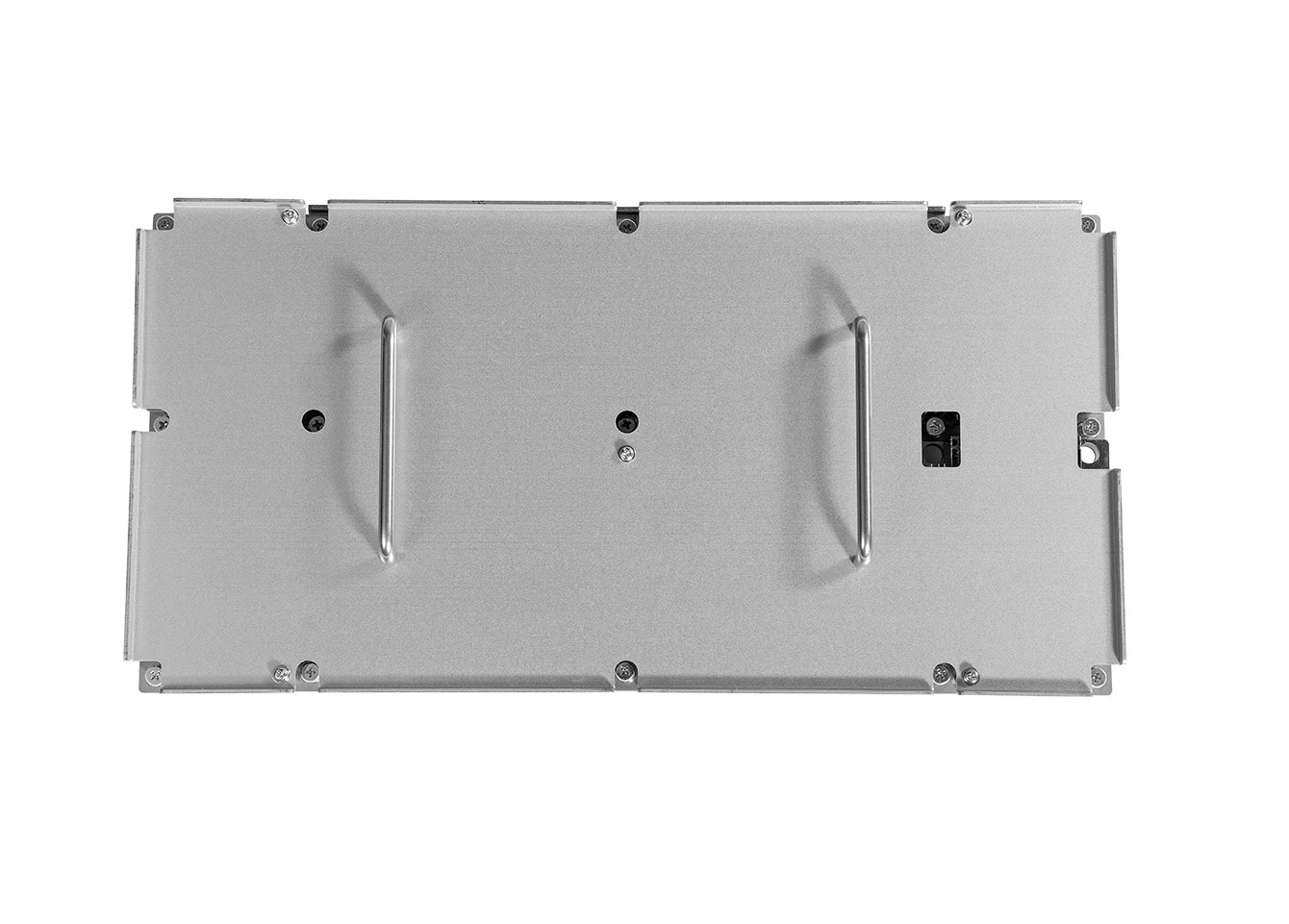

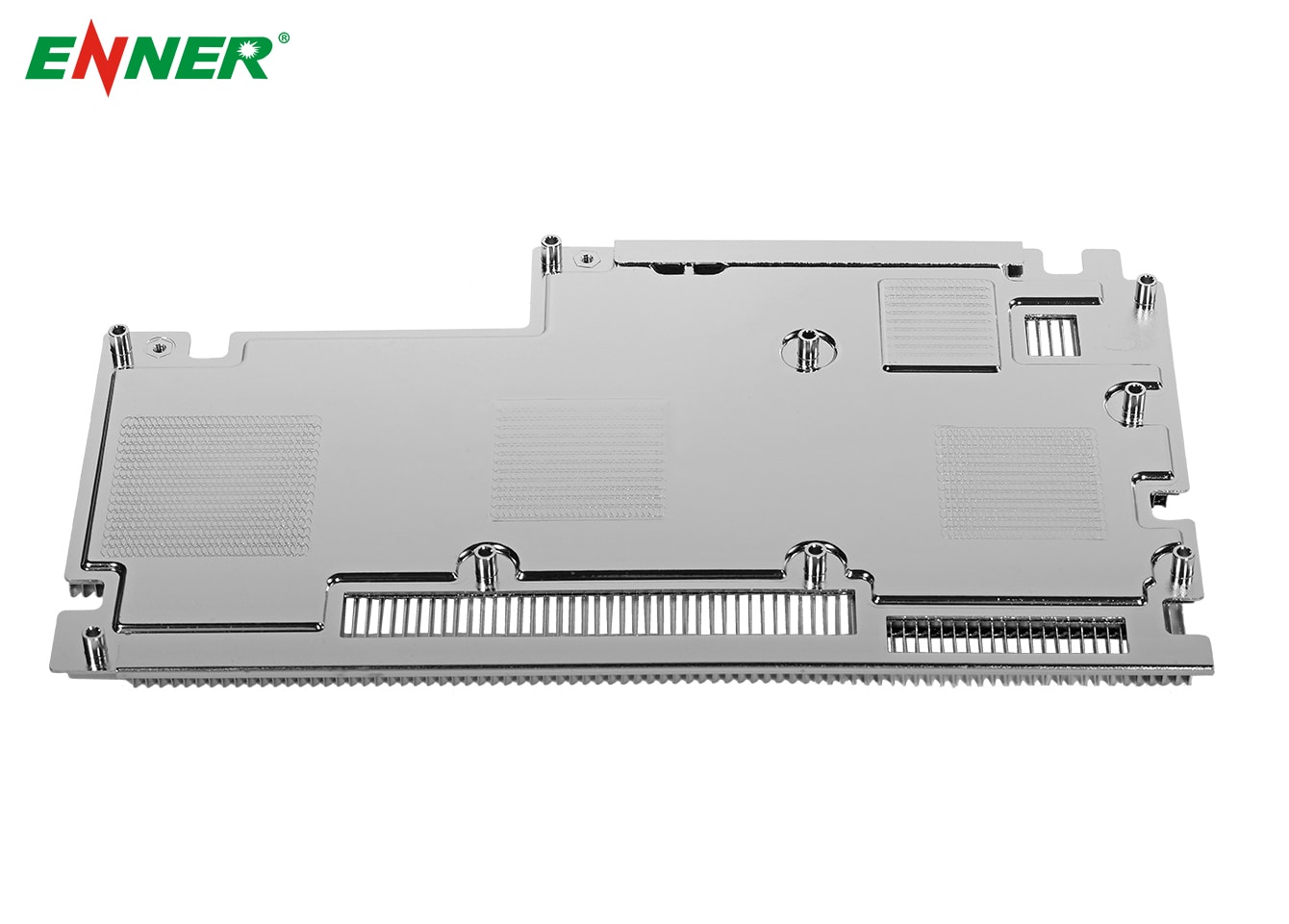

Vapor Chamber Heatsink For Communication

This Vapor Chamber Heatsink is specifically designed for communication equipment, offering efficient heat dissipation to maintain optimal performance in high-power environments. The vapor chamber technology ensures rapid heat transfer, reducing hotspots and enhancing cooling efficiency. Crafted with durable materials, this heatsink is ideal for servers, base stations, and other high-performance networking hardware, ensuring reliability and consistent operation under heavy workloads. Its slim profile allows for versatile installation, making it a perfect choice for space-constrained applications while effectively handling significant thermal loads.INQUIRE NOW -

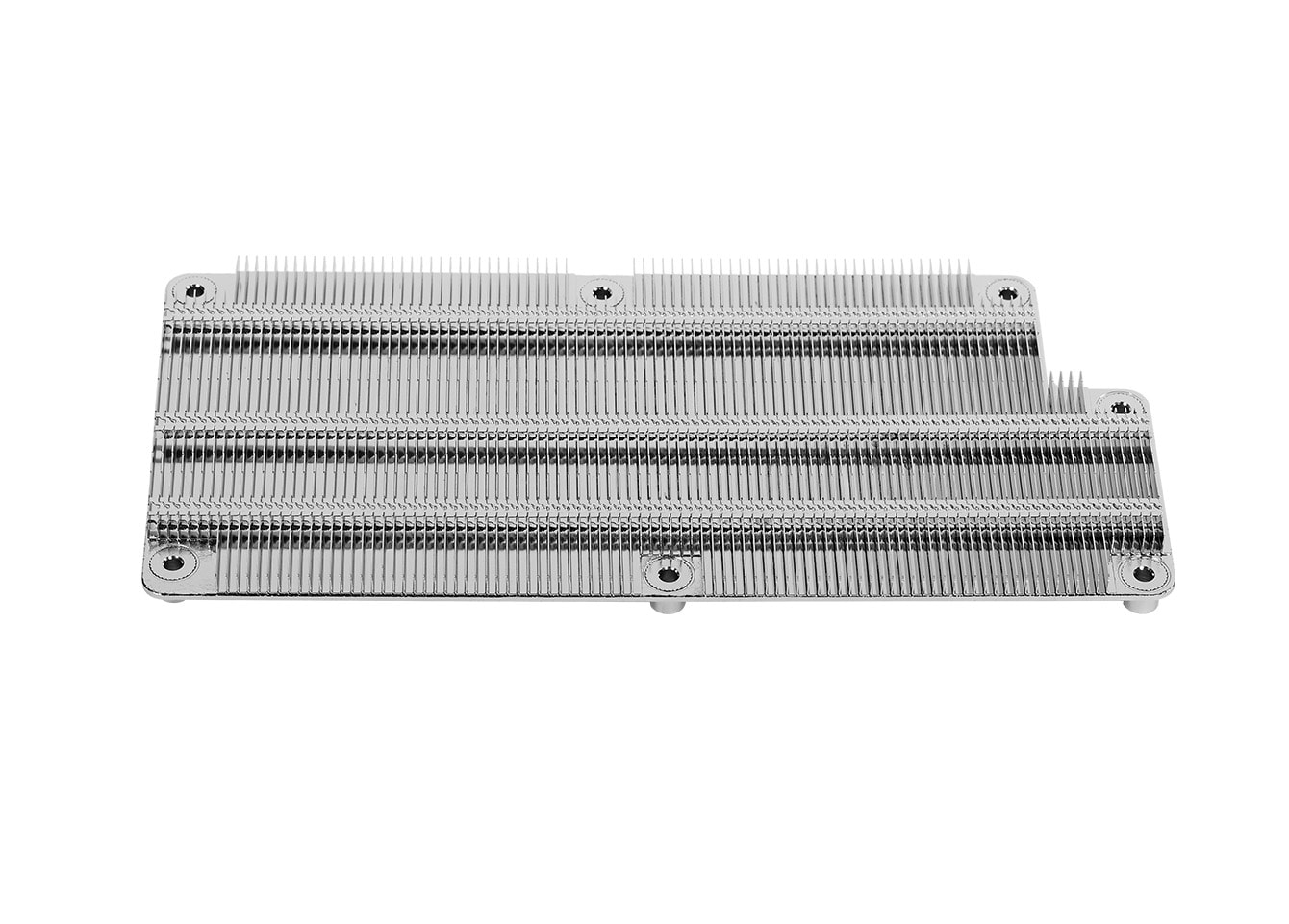

Vapor Chamber Heatsink For Premium Brewer

This Vapor Chamber Heatsink is designed specifically for premium brewing systems, ensuring exceptional thermal management to maintain the precise temperature required for optimal brewing performance. The vapor chamber technology efficiently spreads heat across the entire surface, enhancing stability and preventing overheating. Its compact design allows for easy integration into premium brewing machines, while the high-quality construction ensures durability and long-term reliability. Ideal for commercial and high-end home brewing, this heatsink provides the consistent thermal environment necessary for producing the perfect brew every time.INQUIRE NOW -

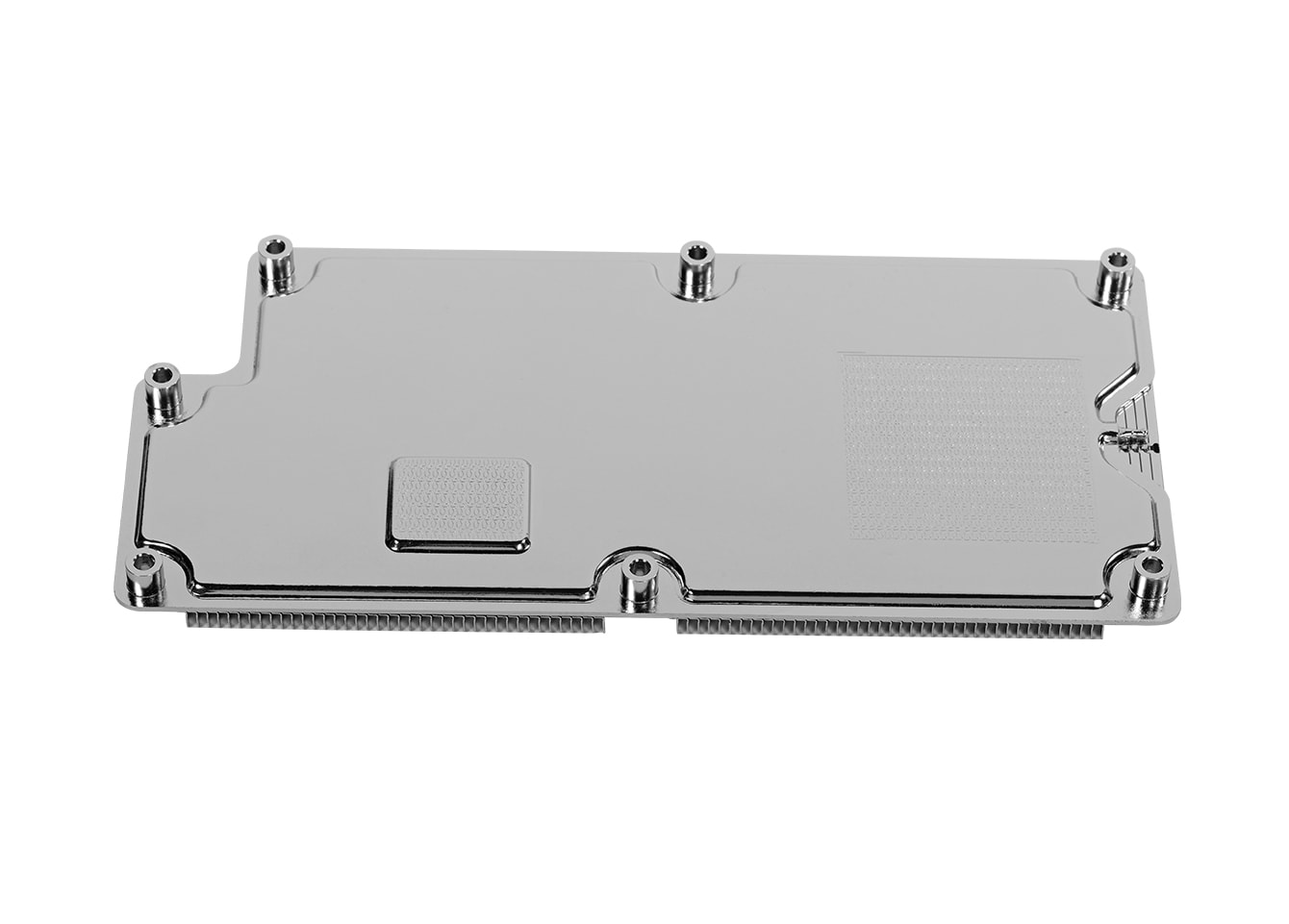

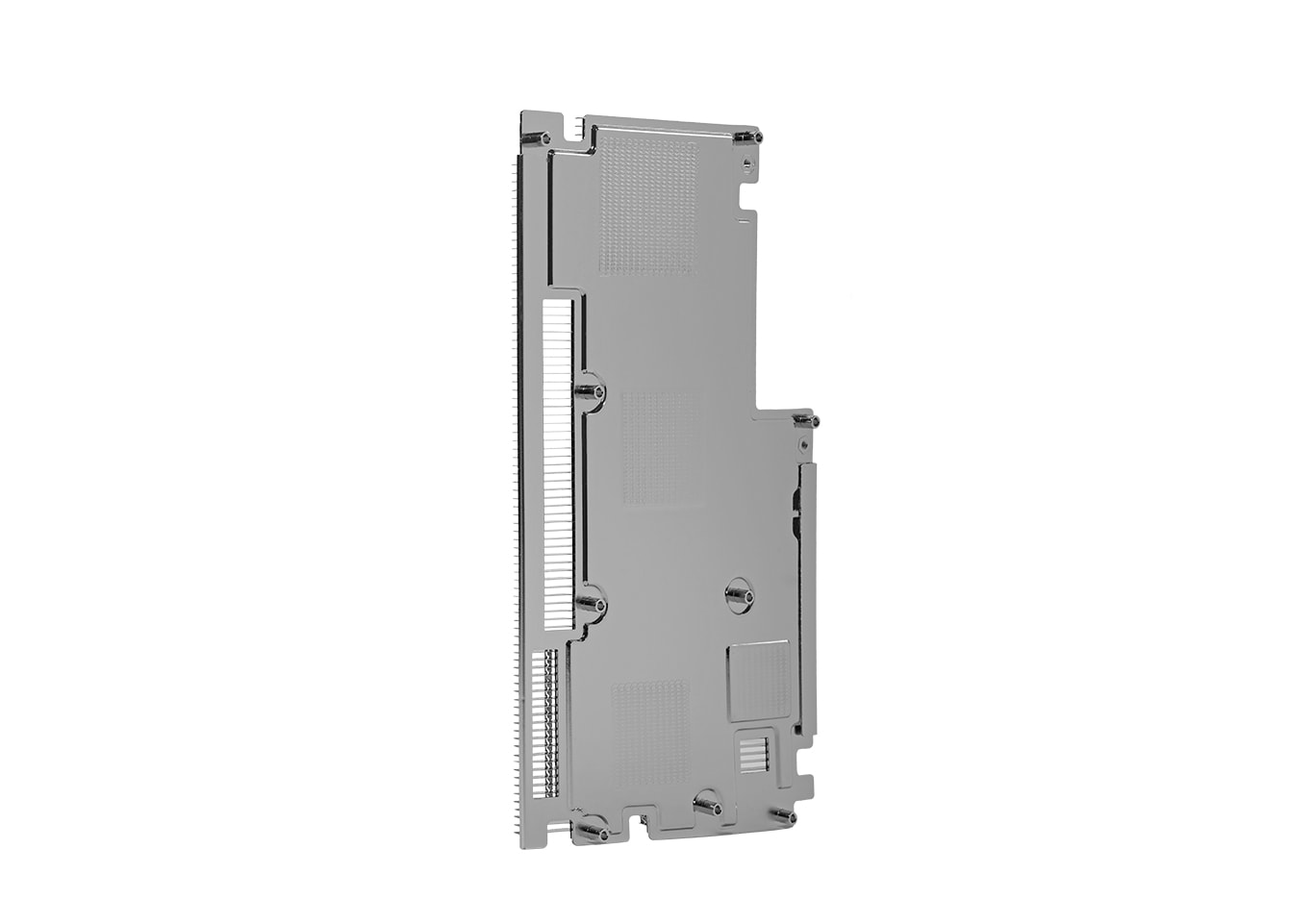

Vapor Chamber Heatsink For Communication

This Vapor Chamber Heatsink is tailored for communication systems, delivering superior thermal performance to meet the demanding cooling needs of networking and telecom equipment. Utilizing advanced vapor chamber technology, it ensures rapid and uniform heat distribution, effectively minimizing hot spots. The robust construction and compact form factor make it ideal for integration into confined spaces within communication infrastructure. This heatsink is engineered for long-term reliability, supporting consistent, high-performance operation of routers, switches, and base stations even under intensive workloads, thereby enhancing overall system efficiency and stability.INQUIRE NOW -

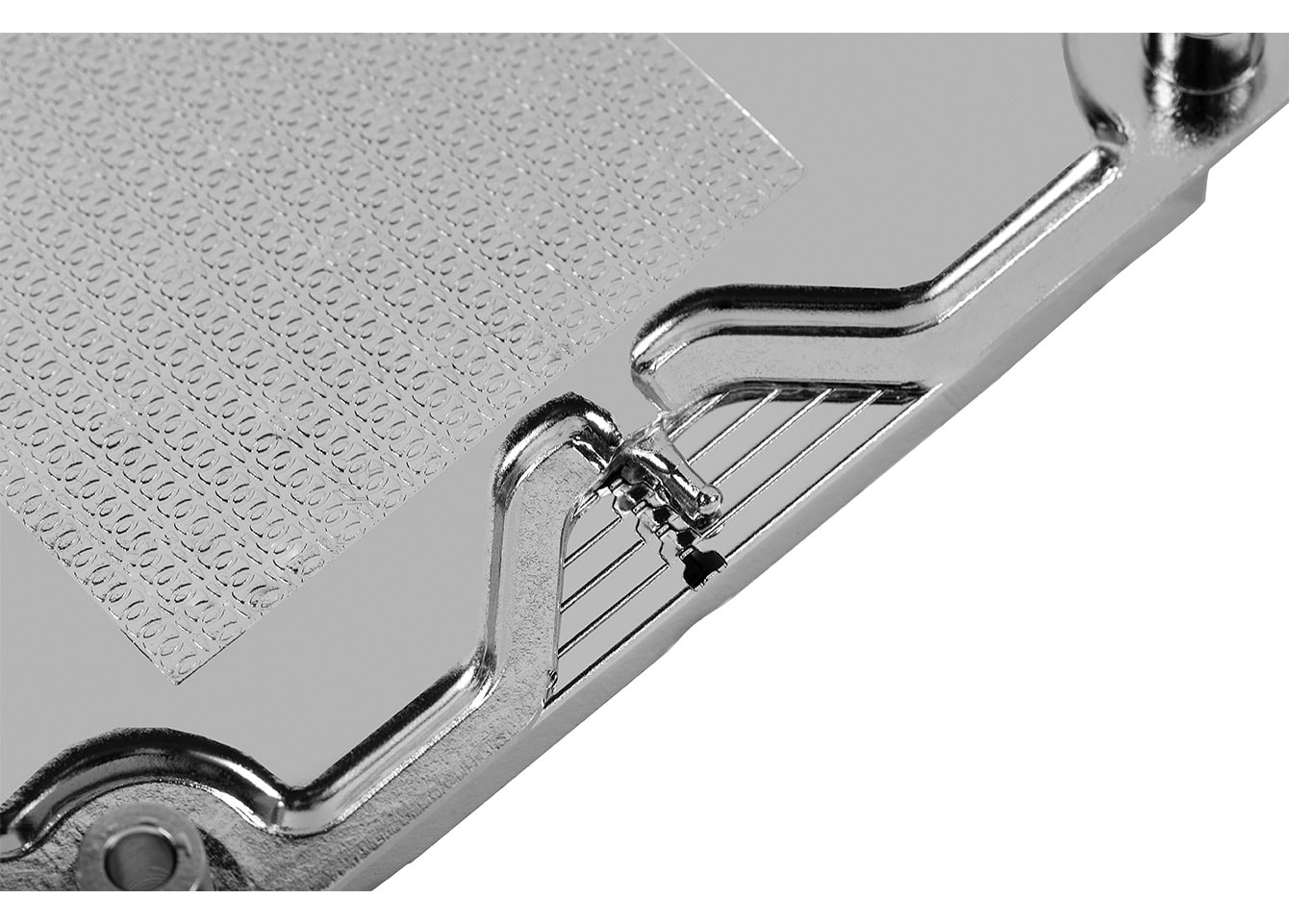

Vapor Chamber Heatsink For Communication

This Vapor Chamber Heatsink is engineered for communication equipment, providing advanced thermal management to optimize system performance. The vapor chamber design ensures effective heat dissipation by spreading heat evenly across the heatsink, thereby minimizing thermal resistance and preventing hotspots. Its durable construction and compact layout make it suitable for various networking devices, including servers, routers, and telecom infrastructure. With enhanced cooling capabilities, this heatsink ensures stable operation of communication systems, even in demanding environments, contributing to the overall efficiency and longevity of your equipment.INQUIRE NOW -

Vapor Chamber Heatsink For Communication

This Vapor Chamber Heatsink is designed for high-efficiency cooling in communication systems, ensuring stable performance and reliability. Featuring a vapor chamber core, it provides superior heat dissipation by spreading heat uniformly across the heatsink surface, minimizing thermal buildup. Its sleek design and durable construction make it ideal for telecom applications such as base stations, switches, and other networking equipment. With this advanced heatsink, communication devices can maintain optimal temperatures even under heavy data loads, ensuring uninterrupted and efficient operations in demanding environments.INQUIRE NOW

Vapor chamber technology is not limited to CPUs and GPUs. It is also utilized in vapor chamber laptops to provide efficient cooling in a slim form factor, as well as in high-performance gaming systems and data centers where gpu vapor chamber solutions are essential for maintaining optimal performance.

Advantages of Vapor Chamber Heatsinks:

-

High Thermal Conductivity:

Vapor chambers offer superior thermal conductivity compared to traditional solid heatsinks, making them highly efficient at transferring heat away from heat-generating components. -

Space-Efficiency:

The thin profile of vapor chamber heatsinks allows for their integration into compact devices, such as vapor chamber laptops, without compromising on cooling performance. -

Silent Operation:

Unlike traditional cooling fans, vapor chamber coolers operate silently, providing a noise-free environment for users. -

Durability:

The lack of moving parts in vapor chamber cooling systems enhances their reliability and longevity, as there is no mechanical wear and tear to consider.

Leave a message!

Our professional team will reach you within 24hrs!

Crystal Xi

Crystal Xi

Leave message

Leave message