You use power modules to change energy safely, but these modules get very hot when they work. If you do not control the heat well, your system can get too hot. This can make it work less well and not last as long. Good heat sink designs can make things cooler by 30%. They can also help energy work better by over 70%. This makes your system safer and helps it work better.

Custom heat sinks help cool power modules better. They fit the size and shape of each module. This makes the modules work well.

Good heat control helps power modules last longer. It lowers the chance of breaking and saves money on repairs.

Special design tools help make custom heat sinks. These tools check how heat moves. This helps pick the best cooling plan before making it.

Custom heat sinks keep things safe by stopping overheating. Overheating can cause electrical problems or fires.

Custom heat sinks cost more at first. But they save money later by working better and using less energy.

There are many power modules in cars and factories. Each one does a special job and deals with heat in its own way.

Automotive electronics power modules are used in cars and trucks. They work with big voltage changes and high heat. You find them in battery management, on-board chargers, and ADAS sensor power supplies.

Motor driver modules help control electric motors. People use them in robots, drones, and machines in factories.

Intelligent power modules have smart parts like IGBTs. These modules can protect themselves from getting too hot or from short circuits.

Power modules change electricity from one type to another. This change makes heat inside the module.

The Seebeck Effect changes heat differences into voltage.

The Peltier Effect makes heat at the places where current goes in or out.

The Thomson Effect adds or takes away heat, depending on which way the current flows.

Big temperature changes can make the materials inside stretch or shrink. If this happens over and over, the parts can get weak and break.

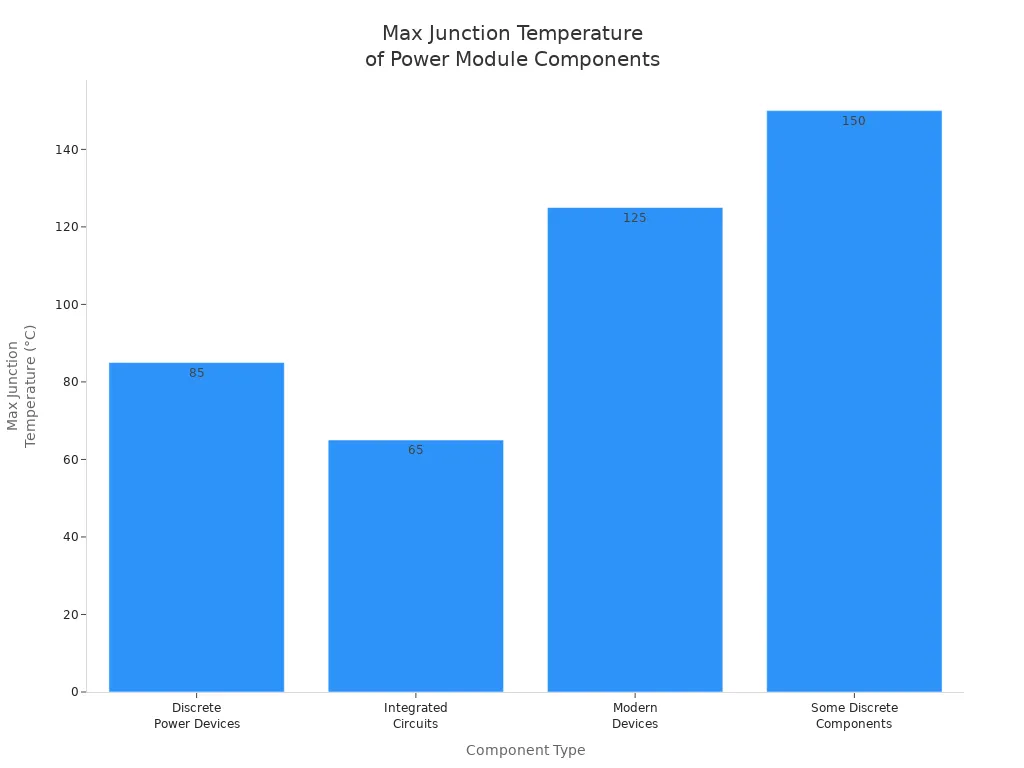

If you do not cool power modules, they can get too hot. Transistors and diodes can only handle certain temperatures.

|

Component Type |

Maximum Junction Temperature |

Reliability |

|---|---|---|

|

Discrete Power Devices |

85°C |

Good Reliability |

|

Integrated Circuits |

65°C |

Varies |

|

Modern Devices |

Up to 125°C |

Varies |

|

Some Discrete Components |

Up to 150°C |

Varies |

You should keep transistors and diodes between -40°C and 105°C. This keeps them safe and working well. If they get hotter, they can break or not last as long. You might need to lower the power if it gets too hot to keep things safe.

Tip: If you manage heat well, your power modules will last longer and stay safe.

Standard heat sinks have trouble keeping power modules cool. There are many problems when you use regular heat sinks.

Thermal resistance can be too high. This makes heat hard to leave the module.

Heat transfer drops if the sink does not fit the module.

High heat flux can make basic designs have hot spots.

You need a heat sink that matches how your module moves heat. If you use a regular design, cooling can be uneven. This can make temperatures go up.

Standard heat sinks do not always fit power modules well. Their shape and size may not match your parts. If the sink does not cover the whole module, some spots stay hotter. This can make weak spots and cause early failure.

|

Problem |

Impact on Cooling |

|---|---|

|

Poor fit |

Uneven temperature |

|

Wrong size |

Reduced heat transfer |

|

Limited contact area |

Higher thermal stress |

Note: A custom heat sink can fix these problems. It matches the size and shape of your module.

Generic heat sinks do not always cool power modules well. They use models that ignore uneven heat. These models think the whole device heats up the same. But real modules have hot spots and changing temperatures.

Makers give thermal resistance numbers, but these may not show how the sink works for you.

Devices using more than 0.5W need careful cooling. If you do not manage heat, your module can get too hot. This can make it less reliable.

Knowing thermal impedances helps keep safe temperatures. If heat cannot leave, your module may get too hot.

Custom heat sinks cool better by fitting airflow and heat patterns. They help keep the temperature even. This lowers thermal resistance and helps your module work well, even when used a lot.

You can use special computer tools to design heat sinks. These tools help you see how heat moves in power modules. You can test different shapes and materials on the computer. This helps you save time and money before building anything.

|

Feature |

Description |

|---|---|

|

Tool Name |

SimScale |

|

Type |

Cloud-based CAE software for heat sink design simulation |

|

Capabilities |

Offers thermal analysis, fluid dynamics, and structural mechanics for optimizing designs |

|

Efficiency |

Allows for virtual evaluation and optimization of designs, saving time and costs in production |

|

Analysis Focus |

Analyzes thermal resistance and conductivity of various heat sink types |

Thermal simulation lets you try many cooling ideas. You can change how solder connects or how air moves. Designers use CFD to see how air flows around fins and channels. You can check if your design will keep the module cool.

Tip: Using simulations helps you find problems early. You can make sure your heat sink works before you build it.

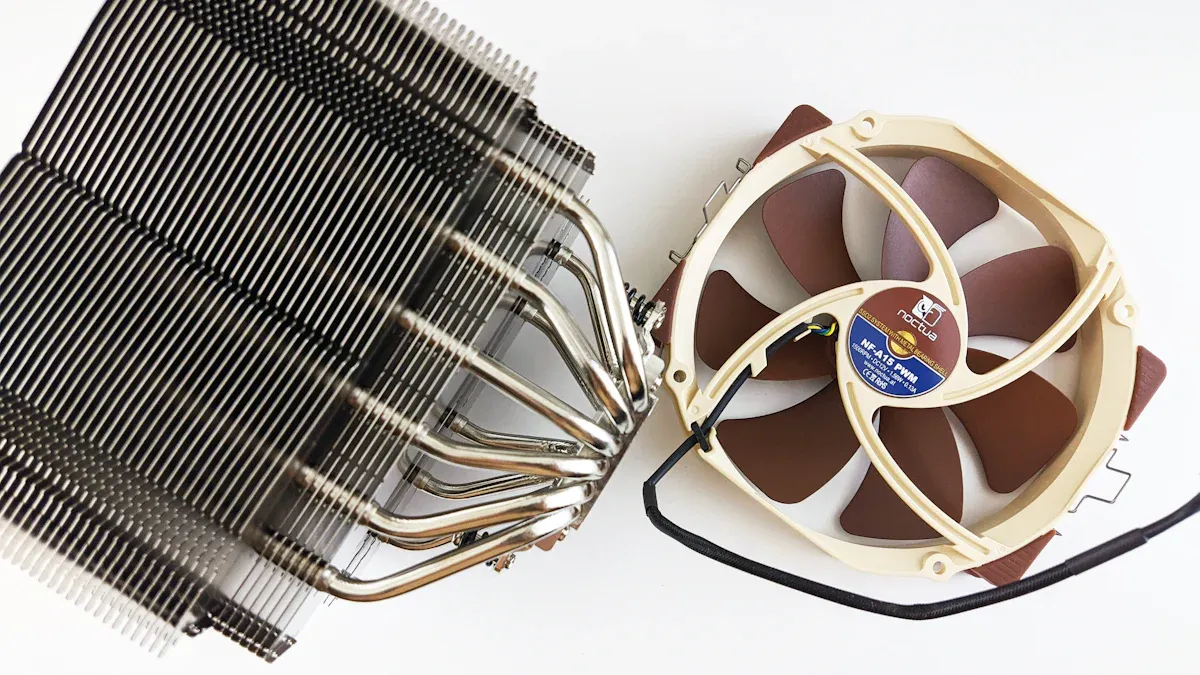

A heat sink needs enough surface area to cool well. More surface area lets more heat leave the module. You can change fin shapes and sizes for better cooling. CNC machining helps you make special shapes that fit your module. You can test different fin patterns and airflow paths to see what works best.

CNC machining lets you make unique shapes.

You can pick materials like copper or aluminum.

Rapid prototyping helps you test ideas fast.

Designers have problems when making custom heat sinks. High temperatures and small spaces make cooling tough. You must balance size, weight, and cost. Bigger heat sinks cool better but may not fit. You need to know how much heat your module makes and how much space you have.

|

Type of Heat Sink |

Cost Implications |

|---|---|

|

Standard Heat Sinks |

Usually cost less than $2.00, good for small projects |

|

Custom Heat Sinks |

Need special tools, cost more at first, cheaper if you make many at once |

Note: Custom heat sinks cost more at first. They work better for big projects and high-power modules.

Matching the heat sink to your power module makes your system safer. Custom heat sinks help control heat and keep modules at safe temperatures. Heat pipes move heat quickly and cool tough spots. Special designs like Z-axis coolers can double cooling for some parts.

|

Aspect |

Description |

|---|---|

|

Thermal Management |

Custom heat sinks keep modules at safe temperatures |

|

Heat Pipe Efficiency |

Heat pipes move heat fast and help cool tough spots |

|

Cooling Capabilities |

Custom designs work for high-power modules where regular sinks fail |

|

Fin Efficiency |

Better fin shapes mean more heat leaves the module |

|

Performance Improvement |

Z-axis coolers can double cooling for some modules |

Custom heat sinks help you follow rules like RoHS, UL, and ISO. You can use safe materials and designs that protect the environment. Good heat sinks help you pass safety tests and meet electronics standards.

Callout: Custom heat sinks give better cooling. They help you follow safety rules and make power modules last longer.

You may have problems with custom heat sinks. High heat flux and low temperature differences make cooling hard. Passive heat sinks may not work if your module gets very hot. You need to watch for high room temperatures and make sure your design fits. Complex designs cost more but give better results.

Custom heat sinks improve thermal performance.

They meet safety and quality standards.

CNC machining makes designs precise and flexible.

Custom heat sinks solve many cooling problems. They help your power modules work better, last longer, and stay safe.

You want your system to work well. Custom heat sinks help move heat away fast. They fit your power module and give better airflow. More surface area helps cool your module. Your module stays cool, even if you use it a lot. You notice your device works better. Cooler parts use less energy and waste less power.

Tip: Custom heat sinks help save energy. You spend less money and help the planet.

Custom designs let you use new cooling methods. You can add liquid cooling or special surfaces. These features help your system handle more power.

You want your power modules to last long. Custom heat sinks keep modules at safe temperatures. This protects the inside parts from heat damage. When you control heat, parts do not break down. Your modules work longer and stay strong.

Custom heat sinks use aluminum, which you can recycle. Makers use extrusion, so they waste less material. You help the earth by picking smart designs.

Using less material means less waste.

Aluminum sinks are easy to recycle.

Better cooling lowers energy use.

Tests show custom heat sinks help modules last longer. Stable heat stops problems. You spend less time and money fixing broken parts.

Safety is important in every system. Custom heat sinks keep power modules safe. A good fit stops hot spots. Even cooling keeps parts from getting too hot. You lower the chance of fire or electric trouble.

Custom heat sinks make your system easy to grow. You can add more parts as you need. Built-in mounts help you install modules fast. These designs work in edge AI, robots, and other systems. You keep processors cool, even when they work hard.

|

Safety Feature |

Benefit |

|---|---|

|

Even cooling |

Stops hot spots |

|

Modular assemblies |

Easy to make bigger systems |

|

Integrated mounting |

Simple to install |

|

Advanced surface finish |

Better heat leaves faster |

Callout: Custom heat sinks protect electronics and help meet safety rules.

Custom heat sinks give better efficiency, longer life, and more safety. Your system works well, lasts longer, and keeps you safe.

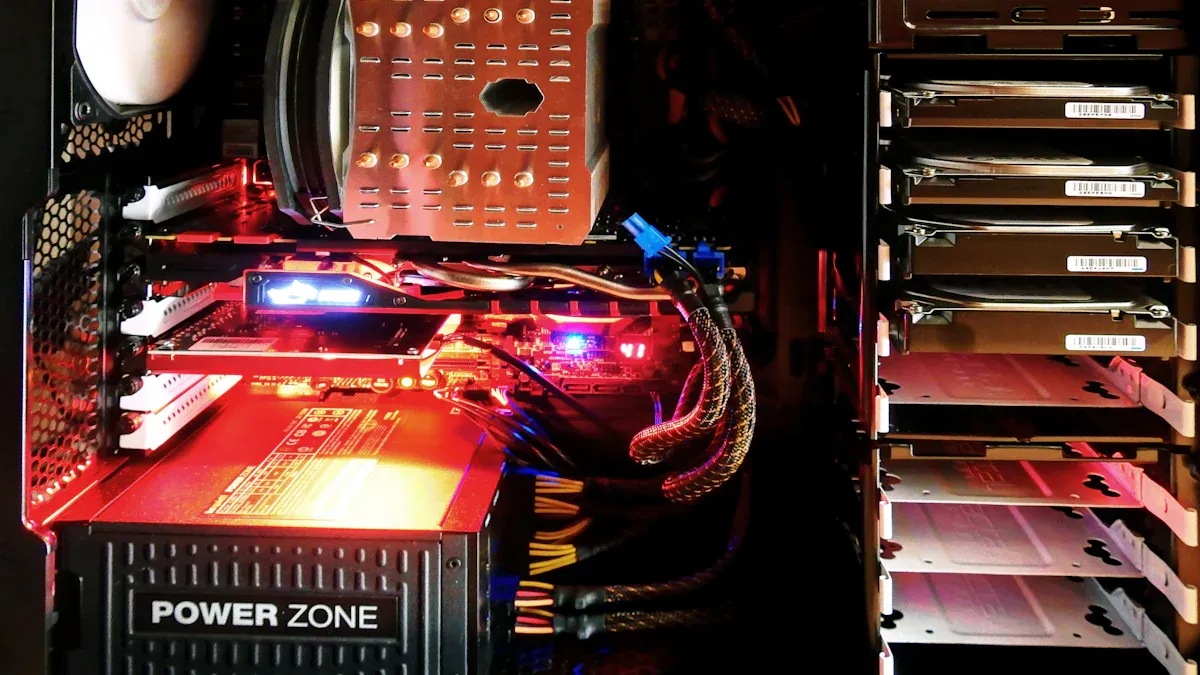

Custom heat sinks are used in many factories. They help machines stay cool and safe. When machines like robots or motor drives run, they get hot fast. Custom heat sinks pull heat away from key parts. This stops too much heat and keeps machines working longer.

Here are some places where custom heat sinks are helpful:

|

Application |

Description |

|---|---|

|

Computer Systems |

Heatsinks take heat away from CPUs, GPUs, and power regulators, especially in gaming computers. |

|

Automotive Electronics |

Heat sinks keep engine control units and other electronics cool in tough places. |

|

Industrial Machinery |

Custom heat sinks stop motor drives and robots from getting too hot. |

|

Audio Amplifiers |

Heat sinks help power transistors stay cool for clear sound. |

Tip: The right heat sink can stop breakdowns and save money on repairs.

Power modules help cars and trucks work safely and smoothly. Custom heat sinks are important for keeping these modules cool. Aluminum heat sinks work well in engines, control units, and lights. They help cars run better, even when it is hot.

|

Evidence |

Description |

|---|---|

|

Customizable Heat Sinks |

Heat sinks keep electronics cool and stop damage from too much heat. |

|

Aluminum Heat Sink |

In cars, heat sinks control heat in engines, control units, and lights, making sure everything works well. |

Callout: Custom heat sinks help car electronics last longer and work better, even in tough places.

You can learn from real custom heat sink designs. Engineers use special shapes to fix hard cooling problems. For example, Intel uses heat pipes and fins with thermal paste to cool CPUs. Tesla uses liquid cooling in battery packs for longer life and safety. NASA uses radiators and heat pipes to keep spacecraft electronics working in space.

|

Case Study |

Objective |

Design |

Outcome |

Impact |

|---|---|---|---|---|

|

Intel’s CPU Heat Sink Design |

Cool high-performance CPUs |

Heat pipes, fins, thermal paste |

Better cooling, no slowing |

Faster speeds, better performance |

|

Tesla’s EV Battery Cooling |

Keep battery packs safe |

Heat sinks with liquid cooling |

Longer battery life, safer |

High-performance EVs, longer driving range |

|

NASA’s Spacecraft Thermal Management |

Handle space temperatures |

Radiators and heat pipes |

Reliable operation |

Success in space missions |

|

Data Center Cooling |

Cool server racks |

Liquid cooling with advanced heat sinks |

More efficiency, reliable |

Growth in cloud computing and big data |

Note: You can make your projects safer and better by using ideas from these custom designs.

Custom heat sinks help keep power modules cool. They stop hot spots from forming. This helps the temperature stay even. When the temperature is even, things work better. Your system can last longer. This is very important for systems that must always work well.

You can listen to experts to get good results.

|

Recommendation |

Benefit |

|---|---|

|

Use metal additive manufacturing |

You get more design choices and better cooling |

|

Choose experienced suppliers |

They know how to solve heat problems |

|

Tailor heat sinks for your application |

Your system works better in hard places |

Think about using custom heat sinks for your next project. They help protect your devices and make them work better.

A custom heat sink matches your power module’s size, shape, and cooling needs. You get better fit and cooling than with a standard heat sink.

Usually, you cannot reuse a custom heat sink for different modules. Each design fits one module’s layout and heat needs. You get the best results with a perfect match.

You should check if your module gets hot or has hot spots. If standard heat sinks do not keep it cool, you need a custom solution.

|

Type |

Cost |

|---|---|

|

Standard Heat Sink |

Lower |

|

Custom Heat Sink |

Higher |

Custom heat sinks cost more at first. You save money later because your system lasts longer and works better.

You often see aluminum and copper used. Aluminum is light and easy to shape. Copper moves heat faster. You choose based on your cooling needs and budget.

By continuing to use the site you agree to our privacy policy Terms and Conditions.