Good battery cooling keeps devices safe and helps them work better. You can use Heatpipe Cooling to control heat in electronics and electric car batteries.

Heat pipes help control temperature better and keep battery heat even. This makes batteries safer.

Finned heat pipes can lower battery heat to 35.6 °C when discharging at 1 C.

Some systems keep battery heat below 50 °C. This shows they manage heat well.

Micro heat pipe arrays help stop batteries from getting too hot or uneven during fast charging.

Heatpipe Cooling helps batteries stay safe and work better. It keeps the temperature even and can lower heat by up to 35%.

Pick the right heatpipe type and working fluid for your battery. This helps make cooling work well.

Make sure heatpipes touch the battery surfaces well. This helps move heat away and stops the battery from getting too hot.

Check heatpipes often for leaks or damage. This keeps cooling working its best.

You can use hybrid cooling systems in small spaces. These use heatpipes and liquid cooling together for better heat control.

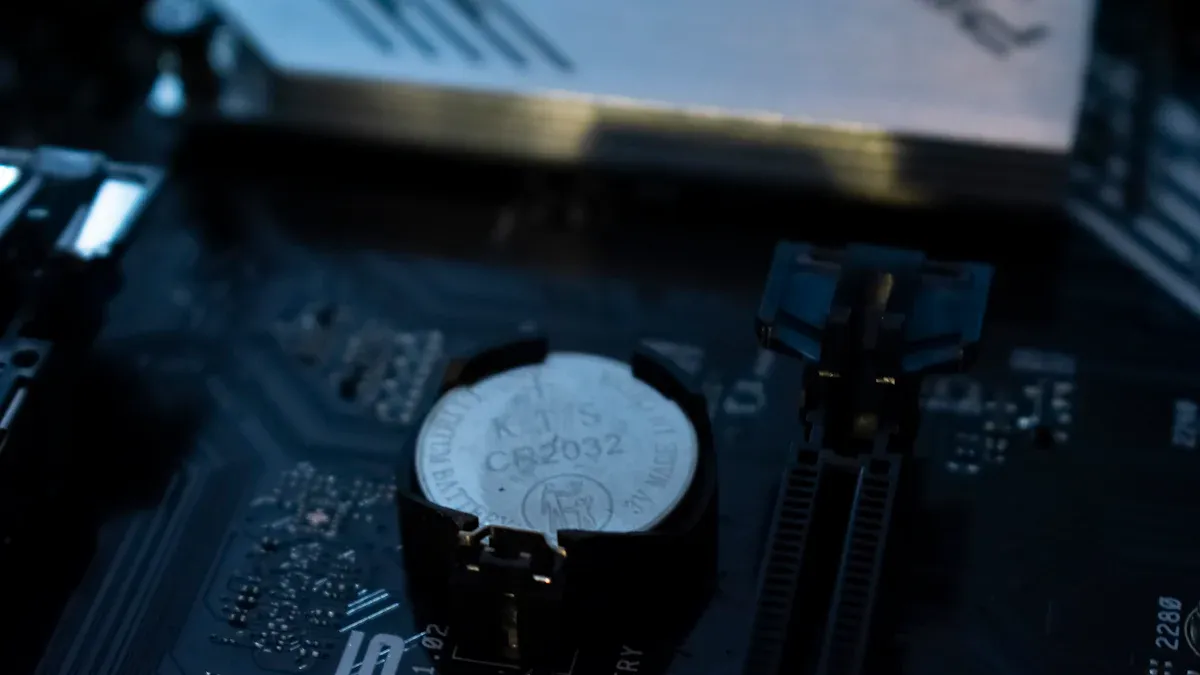

A heatpipe is a special tube that moves heat fast. Most heatpipes have a metal shell that is closed. Inside, there is a little liquid and a spongy material. The pipe gets air and dirt taken out to make a vacuum. This setup helps the liquid move and carry heat well.

Main Body: Closed metal tube shell

Working Medium: Small amount of liquid

Capillary Structure: Porous material for liquid movement

Vacuum State: Air and debris removed

Heatpipes are used in battery cooling systems. They move heat better than many other things.

Heatpipe Cooling uses a simple process. When the battery gets hot, the liquid inside the heatpipe takes in the heat and turns into vapor. The vapor goes to the cooler end of the pipe. There, it lets go of the heat and becomes liquid again. The spongy material helps the liquid go back to the hot end. This cycle keeps happening.

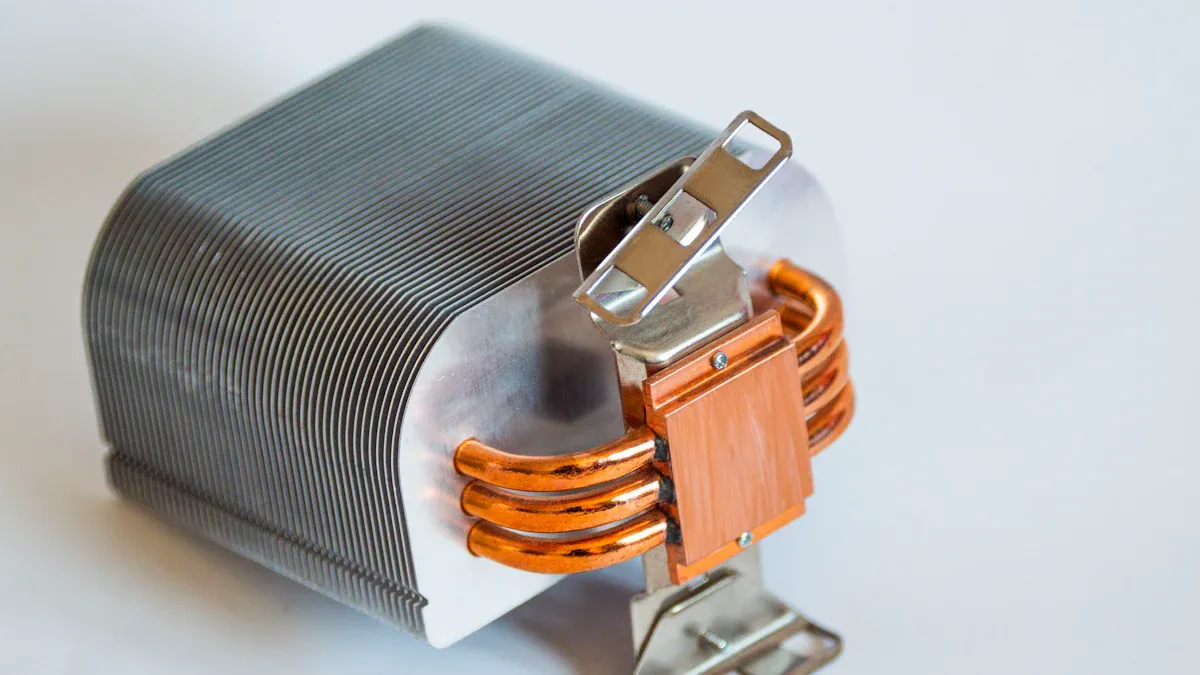

You can pick from different heatpipes for battery systems. Flat single-channel heatpipes fit in small spaces. Oscillating heatpipes move heat with special shapes. Flexible heatpipes bend around corners but need good sealing. Microchannel heatpipes cool small spots very well.

Here is how heatpipe cooling compares to other ways:

|

Technology |

Efficiency Description |

|---|---|

|

Heat Pipes |

High thermal conductivity, transferring heat with minimal temperature difference. |

|

Liquid Channels |

Effective but dependent on flow rate and coolant properties, excelling in managing larger heat loads. |

Heatpipe Cooling has many good points. You can lower battery heat by up to 35%. This helps batteries last longer and work better. Lower heat means safer charging and discharging. You also get less voltage imbalance, so batteries live longer.

|

Configuration |

Max Temperature (°C) |

Temperature Reduction (%) |

Impact on Performance |

|---|---|---|---|

|

Natural Convection |

55.3 |

N/A |

Higher temperatures lead to reduced performance |

|

Heat Pipe TMS |

46.8 |

15% |

Improved temperature management enhances performance |

|

Hybrid TMS |

35.8 |

35% |

Significant heat rejection improves battery life |

New ideas, like the Pulsating Heat Pipe from Hyundai Mobis, help batteries cool faster when charging. These new heatpipes fit in small spaces and spread heat evenly. Using passive cooling systems with heatpipes helps the environment. These systems are easier to recycle and have less impact on climate change.

Tip: Heatpipe Cooling may cost more at first, but you save money later because batteries work better and need less fixing.

Before you use Heatpipe Cooling, learn about your battery. Each battery needs a different way to cool down. You should check how much heat your battery makes. Also, see how fast it needs to cool. Some batteries get hot fast when charging or discharging. Others do not get hot very often.

Use this table to help you know what your battery needs:

|

Decision Attribute |

Description |

|---|---|

|

Thermal Conductivity |

How well the fluid moves heat. |

|

Specific Heat Capacity |

How much heat the fluid can hold. |

|

Compatibility with Heat Pipe Material |

If the fluid works with the pipe material. |

|

Phase Change Temperature |

The temperature when the fluid changes from liquid to vapor. |

|

Latent Heat of Vaporization (LHV) |

How much heat the fluid takes in or gives off during phase change. |

|

Density |

How heavy the fluid is for its size. |

|

Viscosity |

How easily the fluid flows. |

|

Surface Tension |

How well the fluid spreads and fills the pipe. |

|

Cost |

How much money you need for the fluid. |

There are many ways to cool batteries, but not all work well. You should pick a system that is ready to use and fits your battery. Heat pumps and thermally driven systems do not work as well. The coefficient of performance (COP) shows how good a cooling system is. A high COP means your battery will cool better.

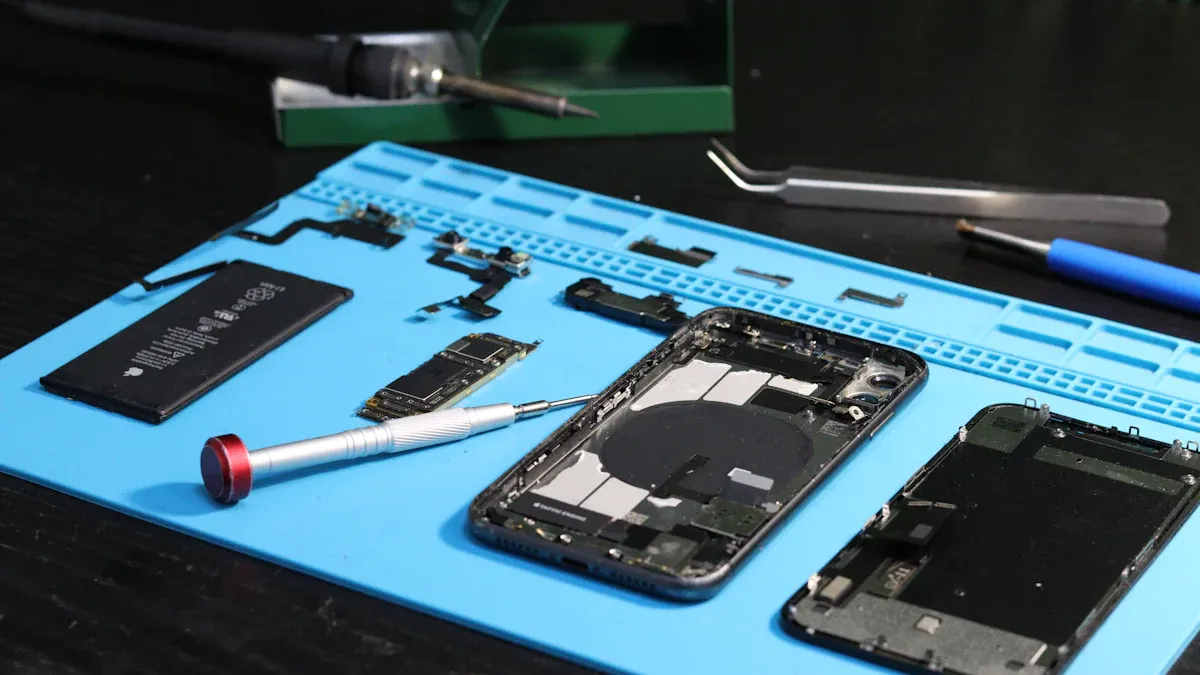

You need the right things to put in Heatpipe Cooling. Here is a list to help you get ready:

Heatpipes (pick the right size and type for your battery)

Thermal paste or thermal epoxy

Press fitting tools

Soldering iron and solder

Insulation materials

Mounting brackets or clamps

Cleaning supplies (alcohol wipes, lint-free cloths)

Safety gloves and goggles

Tip: Always check your battery’s size and shape before you buy heatpipes. This helps you make sure they fit.

Safety is very important when working with batteries and cooling. Wear gloves and goggles to keep your hands and eyes safe. Make sure the battery is turned off before you start. Keep your work area clean and dry. Do not touch battery ends with metal tools. If you use soldering, open a window or use a fan.

Never use heatpipes that are broken.

Do not mix different thermal pastes.

Look for leaks after you put in heatpipes.

Keep things that can burn away from your work area.

Note: If you are not sure about a step, ask an expert for help. Battery safety matters a lot.

You need to pick the right heatpipes for your battery system. First, check the working fluid inside the heatpipe. The fluid must match the shell and wick materials. It should be safe and not harm the environment. The fluid needs to work well at your battery’s temperature. Look for fluids with good vapor pressure and thermal stability.

The working fluid must fit the shell and wick material.

Pick a fluid that is safe and does not pollute.

Make sure the fluid stays stable at high temperatures.

The fluid should work in your battery’s temperature range.

Choose a fluid with the right vapor pressure.

Think about the battery chemistry and the heatpipe material. Some batteries need special heatpipes for their temperature range. The table below shows how different fluids and materials work for different battery types.

|

Working Fluid |

Wick Material |

Temperature Range |

|---|---|---|

|

Helium |

Stainless Steel |

Cryogenic (-271°C) |

|

Water |

Copper |

Electronics (30°C to 150°C) |

|

Lithium |

Stainless Steel/Refractory Metals |

High-Temperature (>1000°C) |

Tip: Always check your battery’s temperature range before you choose a heatpipe. This helps you avoid damage and keeps your system safe.

You must put heatpipes in the right spot for good cooling. Good placement spreads heat evenly and keeps battery cells safe. If you use Heatpipe Cooling with liquid cooling, you can remove more heat and keep temperatures steady. A hybrid system with heatpipes and cooling plates works well in small spaces.

Combine heatpipes with liquid cooling for better heat removal.

Use hybrid cooling structures in small battery packs.

Place heatpipes close to the hottest battery cells.

Make sure heatpipes touch the battery surface for good heat transfer.

Putting heatpipes in the best place lowers the highest temperature. It also reduces temperature differences between cells. This helps your battery last longer and work better.

Note: The number of batteries and their spacing matter. Horizontal and vertical gaps help control heat. You can use computer models to find the best setup.

There are different ways to attach heatpipes to battery modules. Each way has its own good points and problems.

Press Fitting: You press fins over the heatpipes. This gives good thermal contact. You can add soldering for better results, but it is not always needed.

Soldering: You need to plate aluminum with nickel before soldering heatpipes into grooves. Watch the temperature so you do not harm the heatpipes.

Thermal Epoxies: You can use these for prototypes. They make a thin bond and have fair thermal conductivity. You may see a small temperature difference compared to soldering.

The table below shows how cooling setups affect battery temperature.

|

Cooling Configuration |

Heat Output (W) |

Average Cell Temperature |

|---|---|---|

|

SIDO |

0.9028 |

Lower than other methods |

Liquid cooling removes more heat than air cooling. It also keeps battery temperatures even, which helps batteries last longer. You can handle higher power loads with liquid cooling.

The number of batteries and their spacing affect cooling.

You need to check both horizontal and vertical gaps.

Computer models can help you find the best layout.

Alert: Installing Heatpipe Cooling can be hard. You may face high costs and tricky designs. Space can be tight, especially in electric vehicles. Watch for leaks in liquid cooling systems. Air cooling may not keep temperatures steady.

If you follow these steps, you can install Heatpipe Cooling in your battery system. You will improve safety and performance.

You need good thermal contact for Heatpipe Cooling to work. Put heatpipes so they touch the battery surface. Use thermal paste or epoxy to fill small gaps. Clean both surfaces before you attach them together. Dirt or oil can stop heat from moving. Press fitting makes a tight bond. Soldering gives better contact, but watch the temperature. If you see hot spots, check the contact points. Good thermal contact keeps battery temperatures even. It helps the system last longer.

Tip: Use a thin layer of thermal paste. Too much paste can trap heat.

People sometimes make mistakes when installing heatpipes. You might pick the wrong size or type. Always match the heatpipe to your battery’s needs. Do not mix different thermal pastes. Mixing pastes can cause poor heat transfer. Never ignore leaks or cracks in the heatpipe. These problems lower cooling power. If you use liquid cooling, watch for leaks near joints. Air cooling works best when you control air flow and humidity. Put heatpipes close to the hottest cells. This helps spread heat and stops one cell from overheating.

Regular checks keep your cooling system working well. Look for signs of wear or damage on heatpipes. Clean dust and dirt from surfaces. Test the system for leaks every few months. Use a temperature sensor to watch for uneven cooling. If you notice performance drops, check the table below for troubleshooting ideas:

|

Cooling Method |

Description |

Impact on Temperature Uniformity |

|---|---|---|

|

Bar-type Heat Pipe |

Small surface area can cause uneven cooling. |

Bigger temperature difference inside the battery. |

|

Flat Heat Pipe |

Large surface area helps spread heat better. |

Keeps temperature difference within 1 °C. |

|

Air Cooling |

Simple method, light weight, and low cost. |

Lowers battery temperature and spreads heat evenly. |

|

Increased Air Velocity |

Faster air helps move heat away quickly. |

Lowers battery temperature and spreads heat evenly. |

|

Air Humidity Control |

Spraying changes air humidity for better cooling. |

Lowers battery temperature and spreads heat evenly. |

If you see uneven cooling, try flat heatpipes or increase air flow. Clean surfaces and check for leaks. These steps help keep your battery safe and working well.

You can use Heatpipe Cooling in battery systems by doing these things: First, learn what the heat pipe looks like inside. Next, take out air and dirt to make a vacuum. Then, pick the best fluid for your heatpipe. Last, find out how heat travels through the pipe.

If you follow good steps, batteries stay safe and work well. Strong insulation keeps heat from getting too high. Cooling that stays steady helps batteries last longer. You should use sensors to check if batteries get too hot.

If you want to know more, look at these resources:

|

Resource Type |

Description |

|---|---|

|

Advanced Thermal Solutions |

New ideas for managing heat. |

|

Engineering eBooks |

Learn about cooling servers, heat pipes, vapor chambers, and liquid cooling. |

|

Engineering White Papers |

Read about liquid cooling and Peltier coolers. |

|

Energy Storage |

Find out about cold plates and heat pipe coolers. |

|

Vapor Compression Coolers |

See ways to cool things in tough places. |

A heatpipe moves heat away from battery cells. You use it to keep batteries cool and safe. This helps your battery last longer and work better.

You can reuse heatpipes if they stay clean and undamaged. Always check for dents, leaks, or corrosion before using them again. Replace any heatpipe that looks worn out.

You should check battery temperatures with sensors. If all cells stay close to the same temperature, your cooling works well. Hot spots or big differences mean you need to fix something.

Tip: Use a simple temperature chart to track changes over time.

No, heatpipes do not need electricity. They move heat using a special liquid inside. This makes them energy-efficient and easy to use.

Stop using the battery system right away. Leaks can lower cooling power and cause safety problems. Replace the damaged heatpipe before you use the system again.

By continuing to use the site you agree to our privacy policy Terms and Conditions.