5G technology promises speed, bandwidth, and seamless connectivity. But all that power generates something far less desirable—heat. From antennas to processors, 5G components run hotter and denser than ever before. The solution? Choosing the right heat sink materials. With effective thermal management, devices not only stay cool but maintain performance, reliability, and longevity. Let's break down which materials work best for 5G equipment cooling—and why your choice could be the difference between system success and failure.

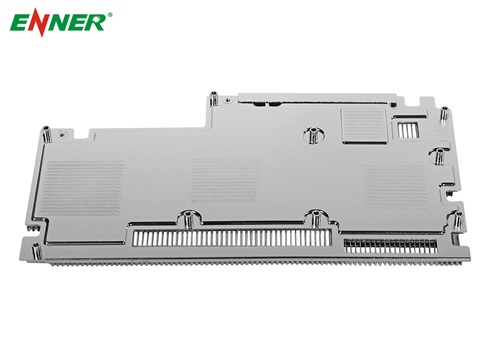

As 5G rolls out globally, it's clear that traditional cooling methods can't keep up. Base stations, small cells, and user equipment are now packed with high-frequency, high-power components in increasingly compact formats. These systems operate in challenging environments, from dense urban rooftops to enclosed equipment cabinets, where ambient airflow is limited.

Unlike 4G infrastructure, 5G involves beamforming antennas, massive MIMO arrays, and real-time data processing, all of which increase thermal load. Poor heat dissipation can lead to signal degradation, reduced power amplifier efficiency, or even total equipment failure. That's why selecting the right heat sink material is critical—it determines how efficiently thermal energy is conducted away from hot zones, ensuring signal quality and system durability.

Not all heat sink materials are created equal. When choosing a material for 5G thermal management, these performance factors come into play:

Thermal Conductivity: The higher, the better. This property defines how well a material can transfer heat. For example, copper exceeds 390 W/mK, while standard aluminum alloys average around 200 W/mK.

Density & Weight: In tower-mounted and mobile applications, lightweight materials reduce structural stress and make installation easier.

Manufacturability: Materials must be easy to extrude, machine, or form into fins, plates, and complex modules.

Corrosion Resistance: Outdoor environments demand materials that can endure humidity, temperature swings, and pollutants.

Cost: Budget plays a role, especially in large-scale deployments, so balancing performance and cost is essential

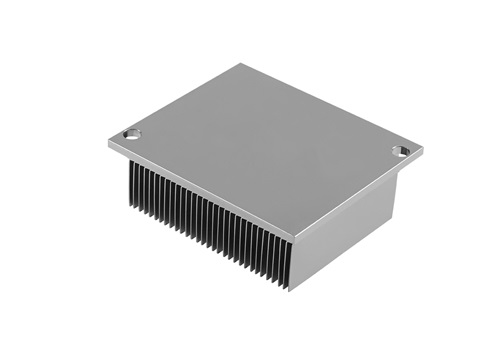

Aluminum is by far the most commonly used material in heat sinks—and for good reason. It strikes a balance between thermal conductivity, weight, and cost. Alloys like 6061 and 6063 are widely used due to their excellent machinability and strength.

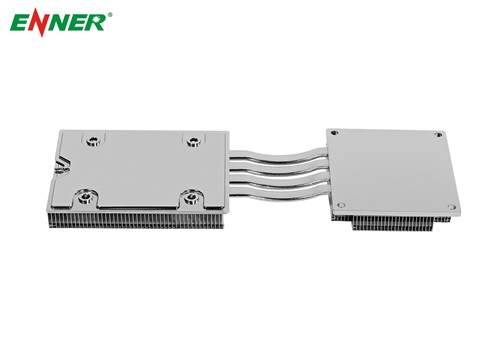

In 5G base stations, aluminum extrusion heat sinks help manage the heat from power supply units and backhaul equipment.

Lightweight aluminum skived fins offer high surface area for air or passive cooling.

For sealed enclosures, anodized aluminum also adds a corrosion-resistant layer.

Aluminum isn't the most conductive option, but it's good enough in most cases and far easier to work with than heavier materials.

When thermal conductivity is the top priority, copper is unbeatable. With a conductivity around 390–400 W/mK, copper is ideal for high-density 5G RF modules and chip-level cooling.

However, copper comes with trade-offs:

It's over twice as dense as aluminum.

It's more expensive and harder to machine.

It's prone to oxidation, requiring protective coatings.

That said, in applications where heat must be removed from a tiny footprint—such as power amplifiers or transceivers—copper's performance is worth the investment.

Advanced 5G systems, especially in mobile or portable units, benefit from graphite-based heat spreaders. These materials combine ultra-high thermal conductivity (up to 600 W/mK) with very low weight and flexibility.

Graphite composites can be layered into thin sheets and added to aluminum frames or PCBs.

They're excellent in space-constrained environments.

Their anisotropic properties (high conductivity in one plane) make them ideal for specific directional cooling.

While they can't fully replace metal heat sinks, graphite materials are perfect complements in hybrid cooling assemblies.

For hot spots with rapidly fluctuating loads, vapor chambers offer a unique advantage: uniform surface temperature. Vapor chambers are sealed, two-phase heat spreaders that use the evaporation and condensation of a working fluid to distribute heat evenly.

Ideal for chipsets or power modules with uneven heat distribution.

Often paired with copper or aluminum bases.

Require precise manufacturing and are more expensive than solid metals.

In 5G, where one side of a component might heat up faster than another, vapor chambers stabilize thermal gradients, preventing hotspots.

Materials like aluminum nitride (AlN) and silicon carbide (SiC) offer both thermal conductivity and electrical insulation. These properties are valuable in high-frequency or high-voltage 5G electronics.

AlN provides thermal conductivity of 140–180 W/mK and high dielectric strength.

Ceramics are inherently corrosion resistant and thermally stable.

Their cost and brittleness limit their use to specialized applications.

They're not commonly used in traditional heat sinks but appear in substrates, housings, and thermal interfaces in critical 5G hardware.

To make an informed decision when selecting heat sink materials for 5G applications, it's essential to weigh performance, weight, and cost side by side. The table below provides a comparative snapshot of the most widely used materials in the field, highlighting their thermal conductivity, density, cost level, and typical 5G use cases. This summary allows engineers and purchasing teams to quickly assess which material aligns best with their project's thermal requirements and budget constraints.

| Material | Thermal Conductivity (W/mK) | Relative Density | Cost Level | Typical 5G Use |

|---|---|---|---|---|

| Aluminum (6061/6063) | 180–210 | 1.0 (baseline) | Low | Base station housings, skived fins |

| Copper | 390–400 | ~2.2× | High | PA modules, chip-level heat sinks |

| Graphite Composites | 300–600 | ~0.5× | Medium | Mobile units, compact RF devices |

| Vapor Chambers | Effective 200–400 | Varies | High | Uneven load areas, chipsets |

| Aluminum Nitride (AlN) | 140–180 | ~1.3× | Very High | Substrate packaging, EMI-sensitive zones |

The ideal heat sink material depends heavily on the use case. For large outdoor base stations, extruded aluminum offers excellent airflow compatibility and structural support. In mobile basebands or edge units, skived or bonded fin heat sinks can deliver high surface area with low weight.

If your application involves thermal hotspots, consider integrating vapor chambers or copper inserts. And for sensitive RF areas, especially those exposed to EMI, ceramic substrates can act as both thermal and electrical barriers.

Cost also plays a role. Aluminum is perfect for large-scale production, while copper and ceramics are reserved for performance-critical modules. The increasing trend is toward composite assemblies, using multiple materials in layered or bonded structures.

The 5G era is still evolving, and so are thermal materials:

Nanomaterials: Researchers are exploring carbon nanotubes and graphene coatings to improve heat transfer.

Phase Change Materials (PCMs): Useful in buffering thermal spikes, particularly for intermittent data surges.

Recyclable Composites: With growing environmental awareness, some manufacturers are developing modular heat sinks with recyclable cores and removable covers.

Integrated Structural Cooling: Devices now incorporate cooling features into the chassis or enclosure, eliminating the need for standalone heat sinks in some scenarios.

Material innovation is becoming just as important as system design in the race for thermal efficiency.

Whether you're designing macro base stations or compact 5G modules, selecting the right heat sink material is a decision that directly impacts cooling efficiency, system life, and performance stability. Each material—aluminum, copper, graphite, vapor chamber, or ceramic—has its strengths depending on your cooling goals. For professional thermal management across 5G applications, Enner offers tailored solutions, from skived and extruded aluminum heat sinks to bonded-fin and vapor chamber designs, ensuring your equipment stays cool and dependable under the most demanding conditions.

Have questions? Reach out via [email protected] or explore our solutions at www.ennergroup.com.

By continuing to use the site you agree to our privacy policy Terms and Conditions.