Every computer runs on a processor that generates heat. Whether you're browsing the web or rendering 4K video, your CPU is always working—and that work creates thermal energy. Without an effective way to manage this heat, performance suffers. Components overheat, systems throttle, and in some cases, damage occurs. That's where the heat sink comes in. It's one of the most essential parts of thermal management in any computing device, especially when it comes to the CPU.

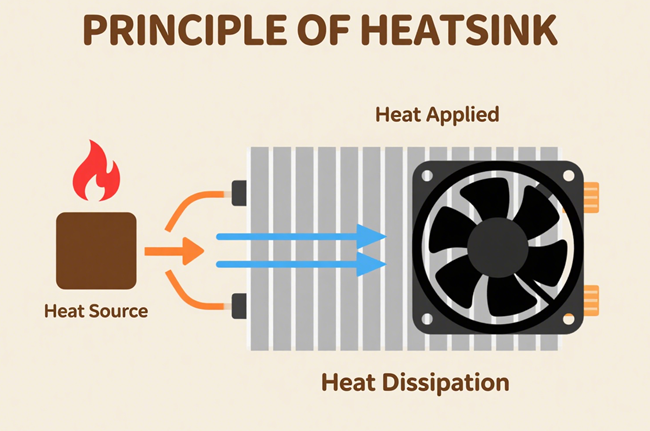

A heat sink is a thermal management device that helps draw heat away from a hot component, typically an integrated circuit like a CPU or GPU. It's usually made of metal—most often aluminum or copper—and is designed with a large surface area to maximize heat dissipation.

The role of a heat sink is to maintain a safe operating temperature. It doesn't cool a component by itself, but it transfers heat to the surrounding air where it can be dispersed more easily. Combined with other cooling methods like fans or thermal interface materials, it becomes the core of an air-based cooling system.

CPUs are the brains of modern computers. They execute millions of operations per second. These operations require electrical current, which naturally produces heat. Without temperature regulation, the CPU can quickly reach unsafe thermal levels.

Excess heat leads to thermal throttling, where the processor slows itself down to prevent damage. Over time, consistently high temperatures can degrade the lifespan of the CPU and other nearby components. Heat sinks provide a passive pathway for thermal energy to move away from the chip, keeping it within its optimal temperature range.

Not all heat sinks are created equal. Their designs vary based on application, performance needs, and budget. Here are the most common types:

Passive Heat Sinks

These rely entirely on natural convection. No fans, no moving parts. They're silent but less effective, usually reserved for low-power CPUs or specialized embedded systems.

Active Air-Cooled Heat Sinks

These include a fan attached to the heat sink to increase airflow and improve heat dissipation. They're the most common solution in desktops and laptops.

Heat Pipe Heat Sinks

These integrate one or more heat pipes into the metal base and fins. Heat pipes move heat quickly from the CPU to the fins using phase-change principles.

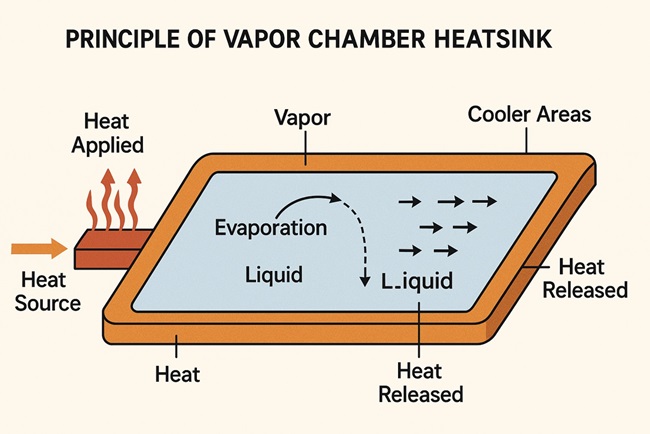

Vapor Chamber Heat Sinks

A step up from heat pipes, vapor chambers spread heat more evenly across the base, offering better performance in compact or high-density designs.

Hybrid Solutions

Some high-end cooling modules combine vapor chambers, heat pipes, and large fans to manage powerful CPUs, especially in gaming PCs and workstations.

The process begins at the interface between the CPU and the heat sink. Thermal paste or a thermal pad is used to fill microscopic gaps and ensure maximum contact.

Once heat enters the base of the heat sink—usually copper or aluminum—it spreads across the surface. From there, it travels into the fins, which offer more surface area for heat to escape. If a fan is present, it pushes or pulls air across these fins, accelerating the cooling process through forced convection.

In more advanced designs, heat pipes or vapor chambers rapidly transfer heat across the base, ensuring hot spots are minimized and the cooling is uniform.

A CPU heat sink might look simple at first glance, but it's an engineered structure made up of several key components:

Each of these parts works together to reduce thermal resistance. Skimping on any single element—like using a weak mounting system or poorly aligned fins—can drastically lower overall cooling efficiency.

The main difference lies in whether or not a fan is involved. Here's a simple comparison:

| Feature | Passive Heat Sink | Active Heat Sink |

|---|---|---|

| Cooling Method | Natural Convection | Fan-Assisted Convection |

| Noise Level | Silent | Audible |

| Maintenance | Low | May require cleaning |

| Cooling Performance | Limited | Moderate to High |

| Use Case | Low-power CPUs | Mainstream and high-performance CPUs |

While passive heat sinks are often used in industrial or embedded systems where silence and durability matter more than raw performance, active heat sinks dominate the consumer market. They're particularly effective in mid- to high-power desktop CPUs, gaming PCs, and laptops. The addition of a fan greatly improves thermal transfer but comes with increased noise and occasional dust buildup. Nevertheless, active solutions strike a strong balance between size, cost, and performance.

Material choice greatly affects thermal conductivity:

Copper has high thermal conductivity (~400 W/m·K), which allows it to absorb and spread heat quickly. It's used in high-end sinks but is heavy and expensive. Some designs use a full copper base for maximum heat absorption and then attach aluminum fins to reduce overall weight.

Aluminum is lighter and cheaper, with good (though lower) conductivity (~200 W/m·K). It's easier to machine and often used in budget or mid-range coolers. Despite its lower conductivity, aluminum performs well when designed with optimized fin structures and sufficient airflow.

Composite Designs use a copper baseplate combined with aluminum fins. This hybrid approach leverages copper's heat absorption and aluminum's lightweight dissipation, making it a common structure in modern tower coolers.

Surface Treatments such as black anodizing or nickel plating are often applied to enhance corrosion resistance, durability, and in some cases, heat radiation. While these coatings don't drastically change conductivity, they improve long-term stability, especially in harsh environments.

Material decisions often depend not just on thermal performance, but also on manufacturing cost, product weight, corrosion resistance, and form factor constraints. For example, laptops may favor full-aluminum designs to reduce weight, while servers might tolerate heavier copper-based modules for thermal stability.

Heat pipes and vapor chambers are advanced thermal technologies that enhance heat transfer.

Heat pipes are sealed metal tubes filled with a small amount of working fluid. When heat from the CPU reaches the pipe, the liquid inside vaporizes, travels to the cooler end of the pipe, condenses, and returns via capillary action. This continuous cycle rapidly moves heat from the CPU base to the fins for dissipation.

Vapor chambers use the same principle but are flat and wider. They spread heat laterally across the entire baseplate. This is especially beneficial for CPUs with multiple cores or large heat-producing zones. Vapor chambers eliminate hot spots more effectively than individual heat pipes.

You'll often find vapor chambers in thin laptops, GPUs, and compact servers, where even thermal distribution matters more than airflow volume. Some large tower-style CPU coolers also include vapor chambers to handle 200W+ thermal loads efficiently.

Using either of these technologies can significantly improve heat sink performance. However, they also add to cost and design complexity, which is why they're usually reserved for high-performance or space-constrained builds.

Heat sinks and liquid cooling each have their place. Here's a quick comparison:

| Aspect | Heat Sinks (Air Cooling) | Liquid Cooling |

|---|---|---|

| Installation | Easier | More complex |

| Maintenance | Minimal | May require refilling, cleaning |

| Noise Level | Moderate | Potentially lower |

| Performance Potential | Good | Excellent |

| Risk of Failure | Low | Leaks, pump failure |

For most users, a high-quality air-based heat sink is more than enough. It's affordable, easy to install, and highly reliable. Liquid cooling, while often associated with lower temperatures and better aesthetics, requires more planning, more parts, and more risk. Unless you're overclocking, running a high-core-count CPU, or optimizing for appearance, a premium heat sink will do the job just fine.

Choosing the right heat sink depends on several factors:

For casual users, a stock cooler might be enough. For gamers, content creators, or engineers running simulations, a high-end tower cooler or hybrid vapor chamber design is worth the investment.

Even the best heat sink won't help if installed incorrectly. Common errors include:

Avoiding these mistakes doesn't require technical expertise—just attention to detail and following instructions carefully. A properly installed cooler will reward you with years of stable performance.

CPU heat sinks are simple in concept, but they play a critical role in ensuring stability and performance in computers of all kinds. From passive aluminum blocks to complex vapor chamber assemblies, they help manage one of the most persistent challenges in electronics: heat. For manufacturers and system integrators seeking high-efficiency, customized heat sink solutions, Enner provides professional-grade thermal components tailored to modern computing needs.

Reach us at [email protected] https://www.ennergroup.com

By continuing to use the site you agree to our privacy policy Terms and Conditions.