| Position | Heat Transfer Rate | Cooling Efficiency | Error Range |

| Tilted (30°) | Higher | Better | ± 4.9% |

| Flat (0°) | Lower | Less | N/A |

| Research | Results |

| Prajapati and Bhandari [13,14] | Taller fins cool better; shorter fins are less effective. |

| Rahmani et al. [15] | Higher fins improve cooling performance. |

| Aziz et al. [17] | Fin height and density boost heat transfer. |

| Haghighi et al. [18] | Proper fin spacing lowers thermal resistance. |

| Joo and Kim [23] | Pin-fin designs cool better than plate-fin designs. |

| Study Focus | Key Results |

| High-Temperature Heat Pipes | Worked well under different conditions without startup issues. |

| Heat Pipes in Electronics | Moved heat from CPUs to fins better than copper . |

| Thermoelectric Integration | Improved heat transfer and lowered thermal resistance. |

| Measurement/Test | Value/Range | Accuracy |

| Thermal Impedance | > 0.01 °C-cm²/W | ±5% |

| Thermal Conductivity | < 20 W/m-°C | ±5% |

| Contact Impedance | N/A | N/A |

| Pad Deflection | N/A | N/A |

| Study Title | Focus | Key Findings |

| Outdoor performance evaluation of a novel photovoltaic heat sinks to enhance power conversion efficiency and temperature uniformity | Photovoltaic heat sinks | Lowered module temperature by 8.45 °C and increased power by 9.56%. Improved temperature uniformity by 14.8% at solar irradiance > 600 W/m². |

| Metric | Value |

| Cooling Capacity | 1046.3 W over 6.25 cm² |

| Cooling Water Flow Rate | 0.63 L/min |

| Lowest Thermal Resistance | 0.0675 °C/W |

| Hotspot Temperature Reduction | 40 °C |

| Total Thermal Resistance Reduction | 59.6 % |

| Required Pumping Power | 23 mW |

| Coefficient of Performance (COP) | 44,810 |

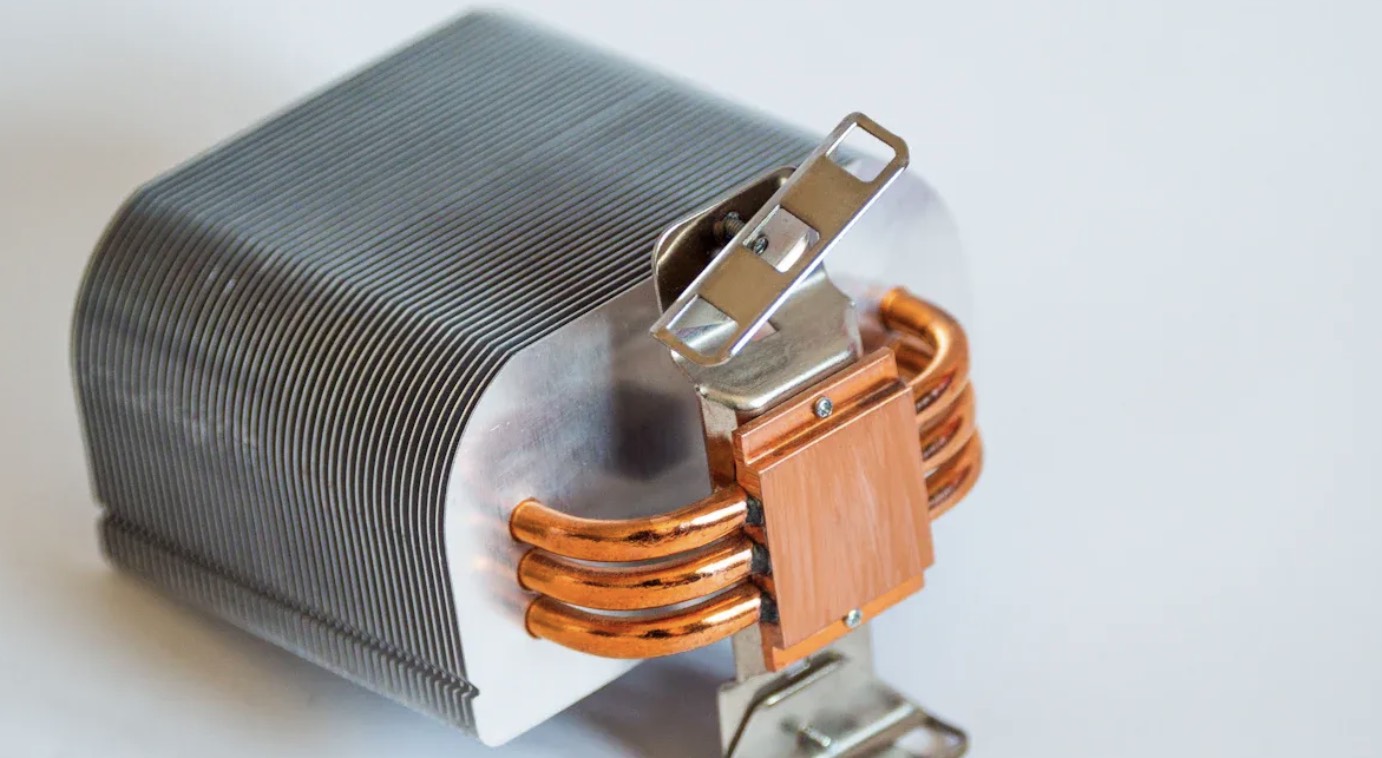

| Heat Sink Type | Cooling Mechanism | Material | Thermal Conductivity (W/mK) | Additional Features |

| Passive | Natural convection | Aluminum | ~235 | Fins for surface area |

| Active | Fan-assisted | Varies | N/A | RPM: 1000-3000, CFM: ~45 |

| Hybrid | Combination | Copper/Aluminum | ~300 | Optimized for weight and heat absorption |

| Study Title | Focus | Key Findings |

| Metal Matrix Composite in Heat Sink Application | Evaluates MMCs for heat sinks | Highlights the importance of material selection and interfacial bonding. |

| Thermal performance evaluation of PCM-MF composite heat sinks | Analyzes PCM-metal foam composites | Shows how material and ambient conditions affect thermal performance. |

| Presenting the Thermal Performance of a Metal Foam-PCM Composite Heat Sink | Examines heat transfer mechanisms | Emphasizes surface area and thermal contact for better heat transfer. |

| Material | Heat Transfer Ability (W/m-K) | Weight (g/cm³) | Price Comparison |

| Copper | 385-400 | 8.96 | 3-4 times pricier than aluminum |

| Aluminum | 167-237 | 2.70 | Affordable for common devices |

| Carbon Composites | 20-500 (design-based) | 1.5-2.0 | Cost depends on production methods |

| Innovation Type | What It Does | How It Helps Devices Last Longer |

| Nano-Coatings | Uses materials like graphene to move heat faster. | Stops overheating and protects parts. |

| Micro-Textured Anodizing | Adds a layer that prevents rust and increases surface area. | Keeps performance steady and avoids heat damage. |

| Composite Layers | Adds coatings with heat-moving particles for better cooling. | Helps parts stay cool and last longer. |

| Thermal Spraying | Adds ceramic or metal layers to improve cooling. | Makes devices more reliable by managing heat better. |

| Laser Surface Texturing | Creates tiny patterns to improve airflow and heat transfer. | Helps devices run smoothly and last longer. |

By continuing to use the site you agree to our privacy policy Terms and Conditions.