You need to choose the right extrusion heat sink to keep your machines safe. Heat sinks help control heat and stop machines from getting too hot. When you choose heat sinks that fit your needs, your machines work better and last longer.

Good heat dissipation helps machines work well.

Safe temperatures stop machines from getting too hot and breaking.

Managing heat well saves energy and stops surprise breakdowns.

Choosing the right heat sink prevents heat damage and keeps your machines working well.

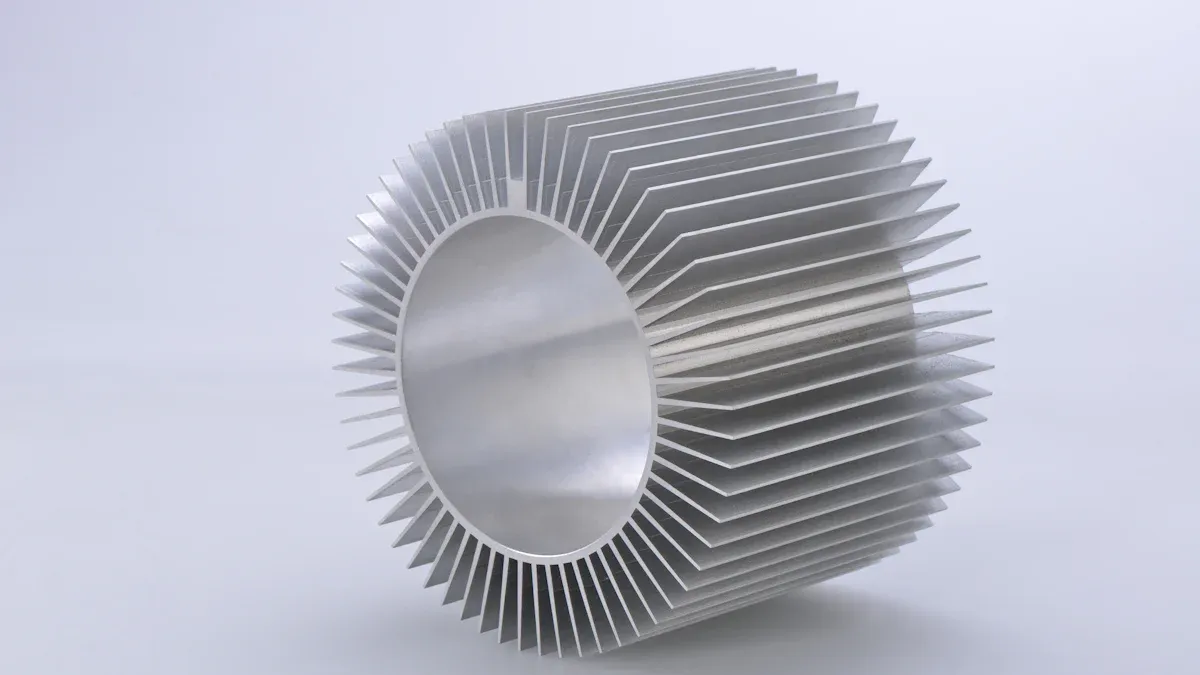

Pick a heat sink that matches your machine’s heat output. This helps stop overheating and keeps things working well. - Think about what the heat sink is made of. Aluminum is usually best for factories. It is not too heavy, not too costly, and cools well. - Look at the shape and style of the heat sink. Some shapes cool better and fit better in your machine. - Check the size and how much surface it has. Bigger surfaces cool better. The right thickness helps move heat away. - Think about how air moves around the heat sink. Good airflow cools things faster. Pick a shape that lets air move easily.

You need to know how much heat your equipment makes before picking an extrusion heat sink. Different industries need different ways to cool things down. For example, automotive systems must cool power electronics. Renewable energy systems need to keep inverters and controllers cool. The table below shows what each sector needs for heat dissipation:

|

Sector |

Heat Dissipation Requirements |

|---|---|

|

Automotive |

Cooling power electronics in electric and hybrid vehicles, and traditional combustion systems. |

|

Industrial Equipment |

Maintaining optimal operating temperatures for motor drives, power supplies, and automation. |

|

Renewable Energy |

Efficient heat dissipation for solar inverters and wind turbine controllers. |

|

Consumer Electronics |

Preventing overheating in devices like gaming consoles and audio amplifiers. |

You should also think about how much heat your application usually makes. High-performance computing and industrial machines make a lot of heat. The table below gives more information:

|

Application |

Description |

|---|---|

|

High-Performance Computing |

Servers and gaming rigs generate significant heat; heat sinks maintain optimal temperatures. |

|

Automotive Electronics |

Manages thermal loads of electronic systems in vehicles, enhancing reliability and safety. |

|

Industrial Machinery and Equipment |

Provides efficient cooling for heavy-duty equipment, reducing thermal-related failures. |

|

LED Lighting Systems |

Ensures effective heat dissipation for LEDs, maintaining performance and extending lifespan. |

|

Telecommunications Infrastructure |

Tailored cooling solutions for servers and networking devices to prevent overheating. |

When you pick the right heat sink, you match its cooling power to your equipment. This helps stop overheating and keeps machines working well.

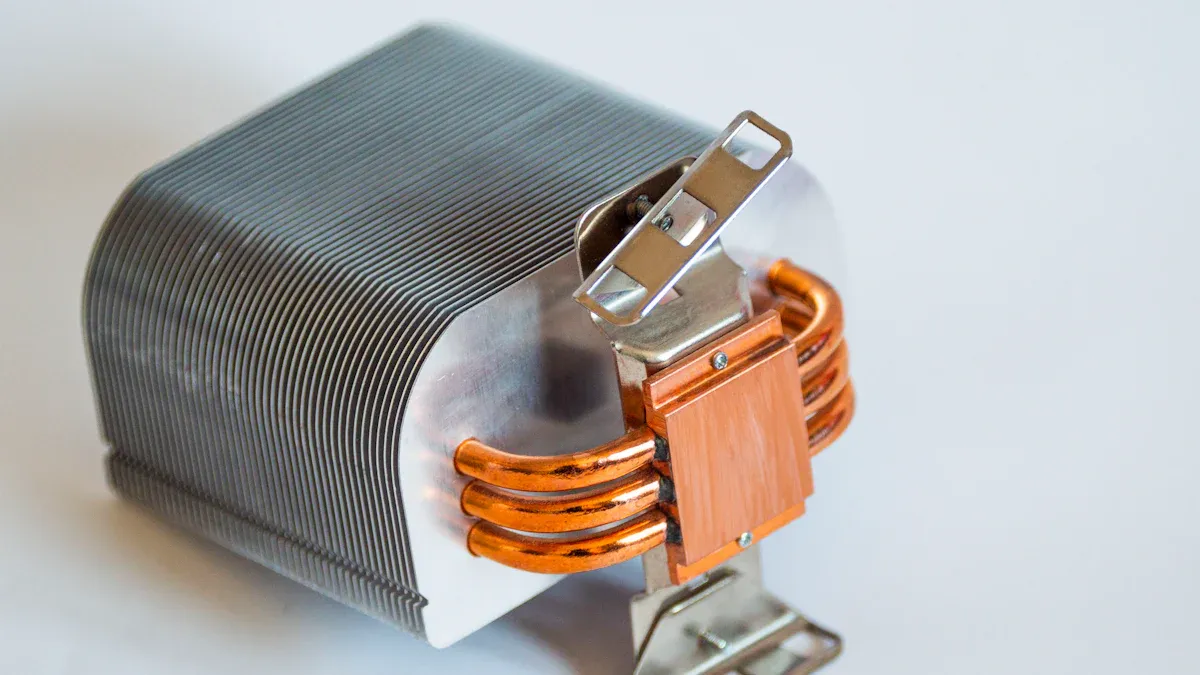

It is important to look at the material when picking an extrusion heat sink. The two main materials are aluminum and copper. Each one has different thermal conductivity and cost.

Pure aluminum has a thermal conductivity of about 237 W/(m·K).

Copper has a higher thermal conductivity, around 398 W/(m·K).

The table below compares some common aluminum alloys used in heat sinks:

|

Alloy |

Thermal Conductivity Values (W/m•K) |

|---|---|

|

1050 |

229 |

|

6061 |

166 |

|

6063 |

201 |

Copper moves heat better than aluminum, but it is heavier and costs more. Aluminum is lighter, easier to shape, and cheaper. Most industrial extrusion heat sinks use aluminum, especially the 6000 series alloys. These alloys are easy to form, machine, and finish. They have magnesium and silicon, which help them work better as heat sinks.

Tip: Using extruded heat sinks instead of machined ones can save about 40% in costs and still give good thermal performance. Aluminum is lighter, so it is easier to move and handle.

When you pick the right material, you balance heat performance, price, and weight. For most industrial jobs, 6000 series aluminum alloys are the best choice.

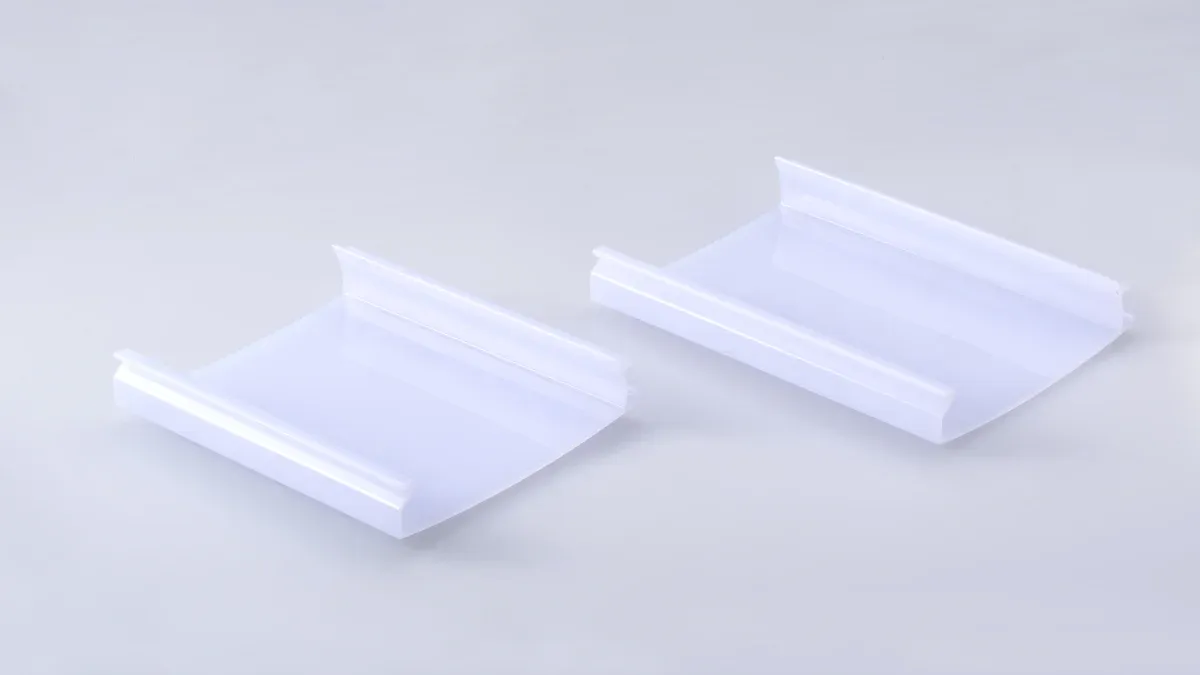

The profile and shape of your extrusion heat sink matter a lot for cooling. Different designs give different performance and cost. The table below lists common heat sink types and their good points:

|

Heat Sink Type |

Advantages |

Cost Level |

|---|---|---|

|

Stamped Heat Sinks |

Low cost, suitable for low-power devices, but lower performance. |

Low |

|

Folded Fin Heat Sinks |

High performance with large surface area, but more expensive to manufacture. |

High |

|

Machining Heat Sinks |

High performance, but expensive due to complex manufacturing process. |

High |

|

Pin-fin Heat Sink |

Effective in low airflow conditions, available in various shapes. |

Moderate |

|

Most popular, efficient, low cost, customizable based on requirements. |

Low |

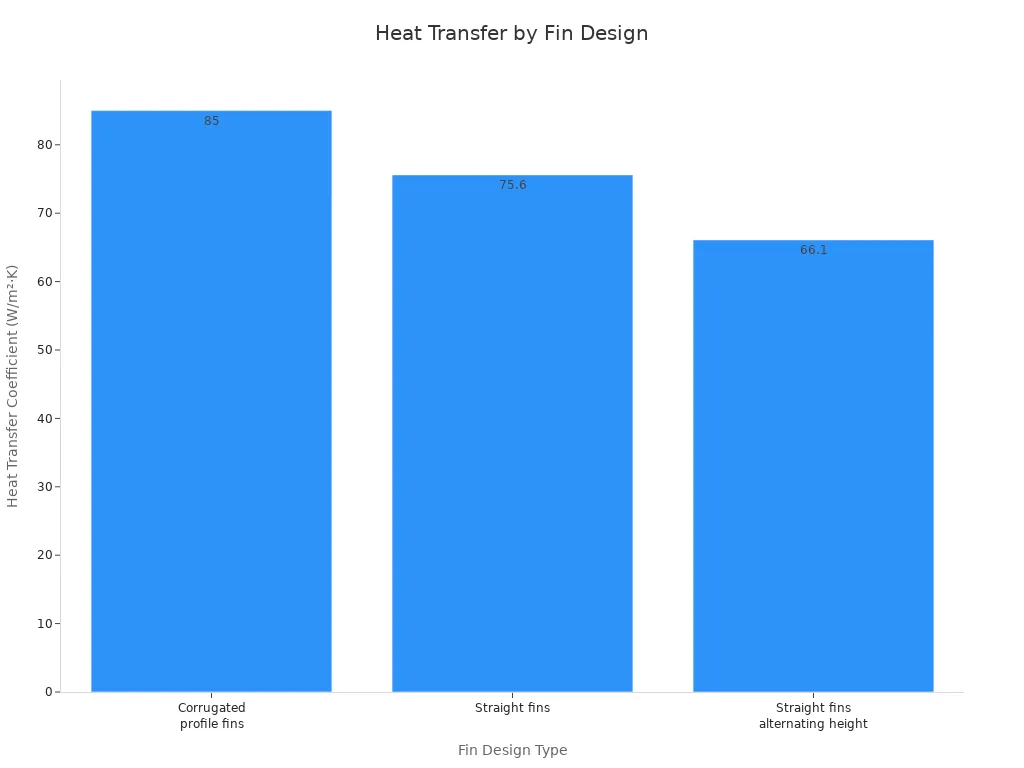

Extruded heat sinks are the most used in factories. You can change their shape to fit your needs. The fin design changes how much heat the sink can move away. The chart below shows how different fin designs compare in moving heat:

Corrugated profile fins move the most heat.

Straight fins and straight fins of different heights move less heat.

When you pick the right profile and shape, you help cooling and make sure the heat sink fits your space and airflow. Always think about what your equipment needs and where it will be used.

You need to look at the surface area when you choose the right extrusion heat sink for your machines. A larger surface area helps the heat sink cool better. More fins or bigger fins give more space for heat to move away from your equipment. Skived heat sinks can have thinner and closer fins, which means they cool even more. Extruded heat sinks have limits on how thin and close the fins can be. This can lower how well they cool.

More surface area means better cooling.

Skived heat sinks have more surface area than extruded ones.

Extruded heat sinks work well but have limits on fin size and spacing.

Thickness is important for both the base and the fins of your heat sink. The right thickness helps move heat away from your device. If the base is too thin, it cannot spread heat well. If it is too thick, it adds weight and cost.

You can find extrusion heat sinks with base thickness from 0.1 mm to 0.56 mm. You should match the thickness to your cooling needs and space.

Weight and mounting space matter when you install a heat sink. Lighter heat sinks, like those made from aluminum, are easier to handle and install. You need to make sure the heat sink fits inside your equipment enclosure. The table below shows standard size limits for industrial heat sinks:

|

Item Type |

Heat Sink Enclosure |

|---|---|

|

Material |

Aluminum, Copper |

|

Size |

Standard or customized size |

|

Thickness |

0.4mm-20mm or Customized |

|

Length |

Customized length |

|

Item Type |

Extruded Heat Sink Enclosure |

|---|---|

|

Material |

6000 series, 7000 series |

|

Thickness |

General profiles thickness: 0.8 – 5.0 mm; Anodized protection thickness: 8 – 25 um; Powder coating color thickness: 40 – 120 um. |

|

Length |

3m~6m or more per piece. Customized request available. |

You also need to think about how you will mount the heat sink. Some designs use adhesive tapes or clips. The heat sink must fit in the space you have and work with your mounting method. When you choose the right size and weight, you make installation easier and keep your machines safe.

It is important to think about airflow when you look at extrusion heat sinks. The way air moves and how fast it goes can change how well your heat sink cools things. If you set up the airflow correctly, your equipment stays cooler. Bad airflow makes heat build up and raises thermal resistance. You can make airflow better by picking a heat sink shape that lets air move easily. This helps air go faster and stops air from skipping the fins. Sometimes, you need a bigger heat sink if there is not much air moving past it.

Airflow direction and speed change how heat moves.

Good airflow helps cooling work better.

Bad airflow makes it harder for heat to leave.

The shape of the heat sink can help air move easier.

Bigger heat sinks are needed if airflow is low.

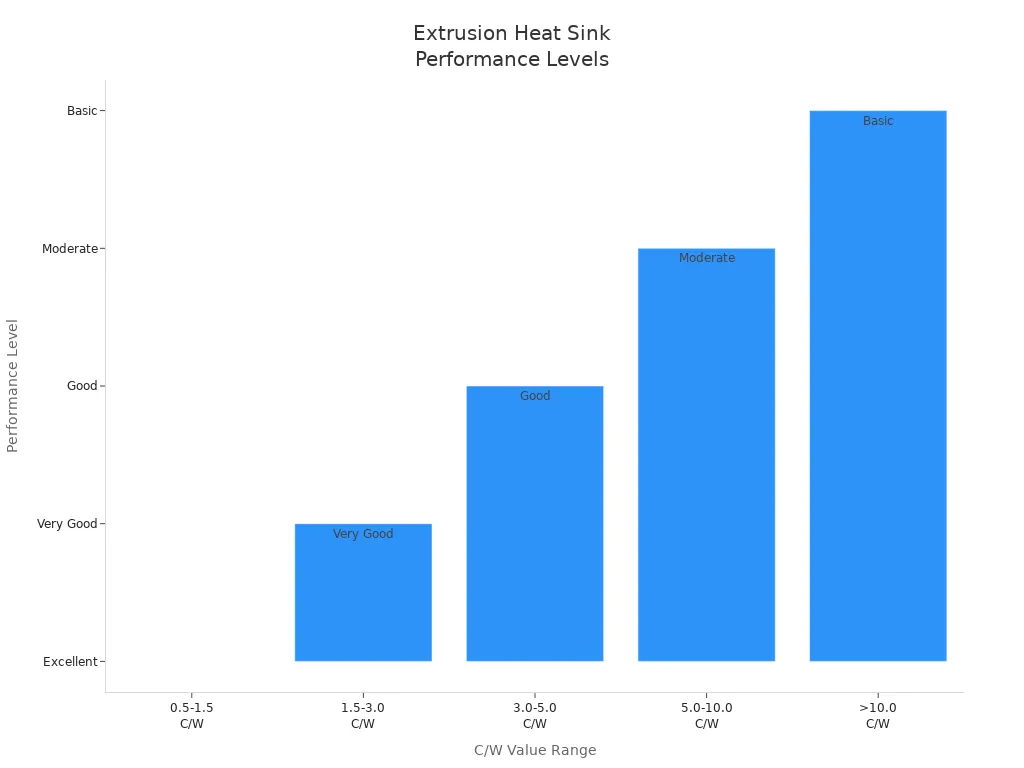

You can check how well a heat sink works by looking at some numbers. The C/W value tells you how good a heat sink is at moving heat away. Lower C/W values mean the heat sink cools better. The table below shows how different C/W values match up with performance:

|

C/W Value Range |

Performance Level |

Typical Applications |

|---|---|---|

|

0.5-1.5 C/W |

Excellent |

High-power computing, server components |

|

1.5-3.0 C/W |

Very Good |

Desktop computers, power electronics |

|

3.0-5.0 C/W |

Good |

Consumer electronics, LED lighting |

|

5.0-10.0 C/W |

Moderate |

Low-power components, signal processing |

|

>10.0 C/W |

Basic |

Simple electronics, minimal heat loads |

You should test heat sinks before you pick one. Some ways to test include looking for bent fins, checking the size, measuring how well it cools, testing airflow, and seeing how it works in tough conditions. These tests help you find problems and make sure the heat sink cools well.

|

Testing Method |

Description |

Tools Used |

|---|---|---|

|

Visual Inspection |

Finds problems like bent fins, bad coating, or dirt. |

Magnifying lamps, borescopes, optical comparators |

|

Dimensional Inspection |

Checks the size and shape for good cooling. |

CMMs, calipers, micrometers, laser scanners |

|

Thermal Resistance Measurement |

Measures how much the temperature changes between the heat source and the air. |

N/A |

|

Airflow Performance Testing |

Tests how well the heat sink cools with different air speeds. |

N/A |

|

Environmental Stress Testing |

Checks if the heat sink works well in tough conditions over time. |

N/A |

You need to think about price when you choose a heat sink. Extrusion heat sinks usually cost between $2 and $5 each. This makes them good for projects that do not have a lot of money. Cold forged heat sinks cost more, about $15 to $20 each. You might use these for jobs that need better cooling.

Tip: Always compare price with how much cooling you need. Buying a lot at once can make each heat sink cheaper. Try to get the best value for your project.

You should check how good the supplier is before you buy heat sinks. Good suppliers make heat sinks with the right size, even fins, and smooth surfaces. This helps your heat sink work better.

The best suppliers offer standard and custom shapes for different cooling needs.

They use strong aluminum alloys like 6063 and 6061 for better cooling and longer life.

Reliable suppliers have lots of experience making aluminum parts and stamping metal.

Their products are made to manage heat well in many types of machines.

You get better results when you pick a supplier with good materials and a strong history.

Picking the right extrusion heat sink means you need to think about how well it cools, how much it costs, if you can change its design, and what your machines need.

|

Decision Point |

Skived Heat Sink |

Extruded Heat Sink |

|---|---|---|

|

Thermal Performance |

High fin density for effective cooling |

Wide gaps may waste cooling potential |

|

Cost Considerations |

Higher per-unit price, no tooling costs |

Low piece price, expensive tooling |

|

Customization Options |

Unparalleled design freedom |

Limited customization |

|

Application Requirements |

Ideal for high-performance, custom needs |

Best for high-volume, standard designs |

You can make your machines work better if you follow some steps. First, pick a heat sink that matches how much heat your machine makes. Next, choose the right material and shape for your needs. Then, check the quality while the heat sink is being made.

When you balance cooling, price, and how well it works, your machines last longer and you spend less money. If you are not sure what to do, you can ask experts like Getec. They can help you with special designs and quick production.

You get better cooling for your machines. Extrusion heat sinks move heat away fast. This helps your equipment last longer and work safely.

Check how much heat your device makes. Look at the space you have. Pick a heat sink with enough surface area to cool your equipment. Always measure before you buy.

Yes, you can use copper. Copper moves heat better than aluminum. It costs more and weighs more. Most people use aluminum because it is lighter and cheaper.

You can check the temperature of your device when it runs. If it stays cool, the heat sink works. You can also look for bent fins or damage.

Sometimes you need a fan. If your equipment makes a lot of heat or has little airflow, a fan helps move air over the heat sink. This improves cooling.

By continuing to use the site you agree to our privacy policy Terms and Conditions.