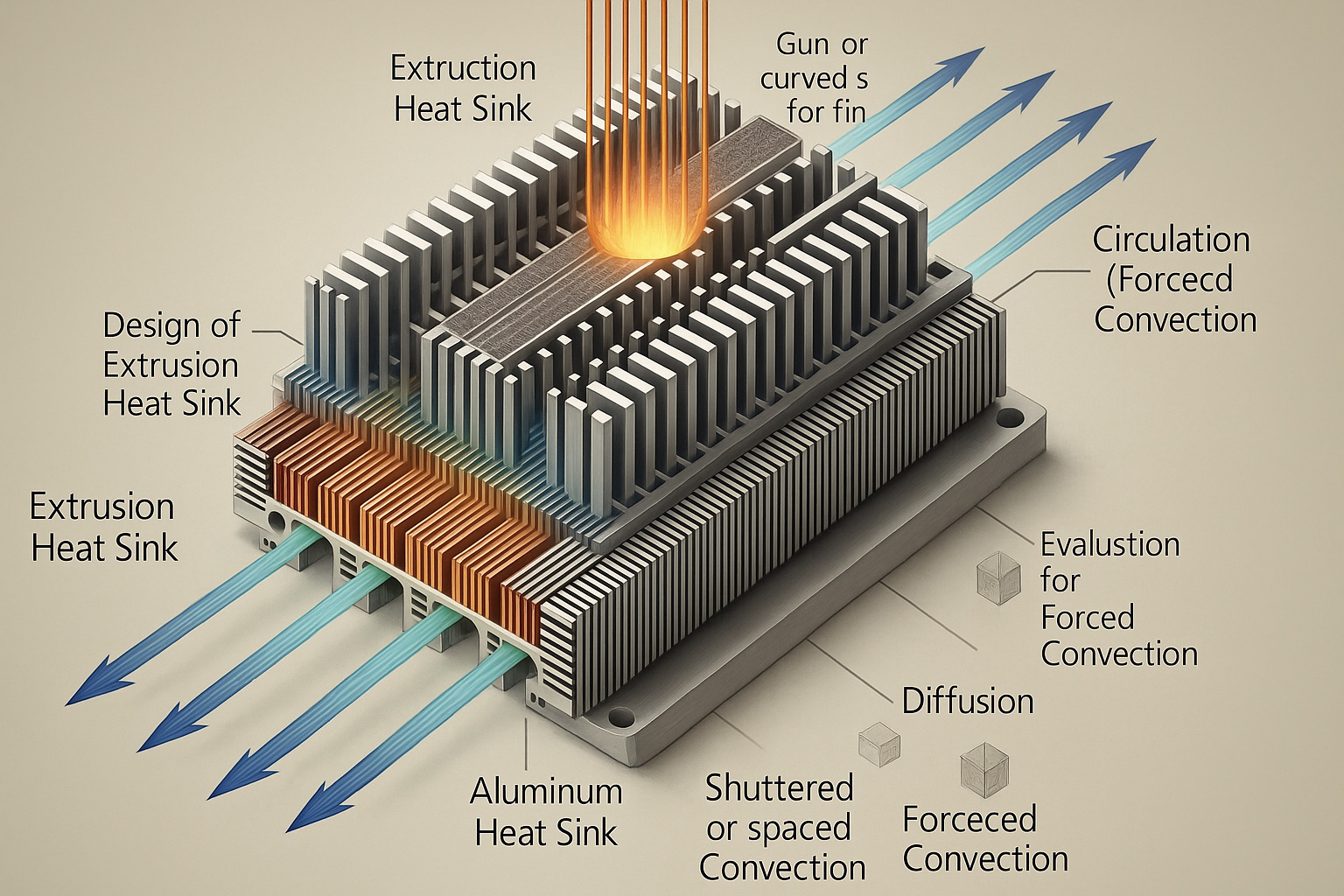

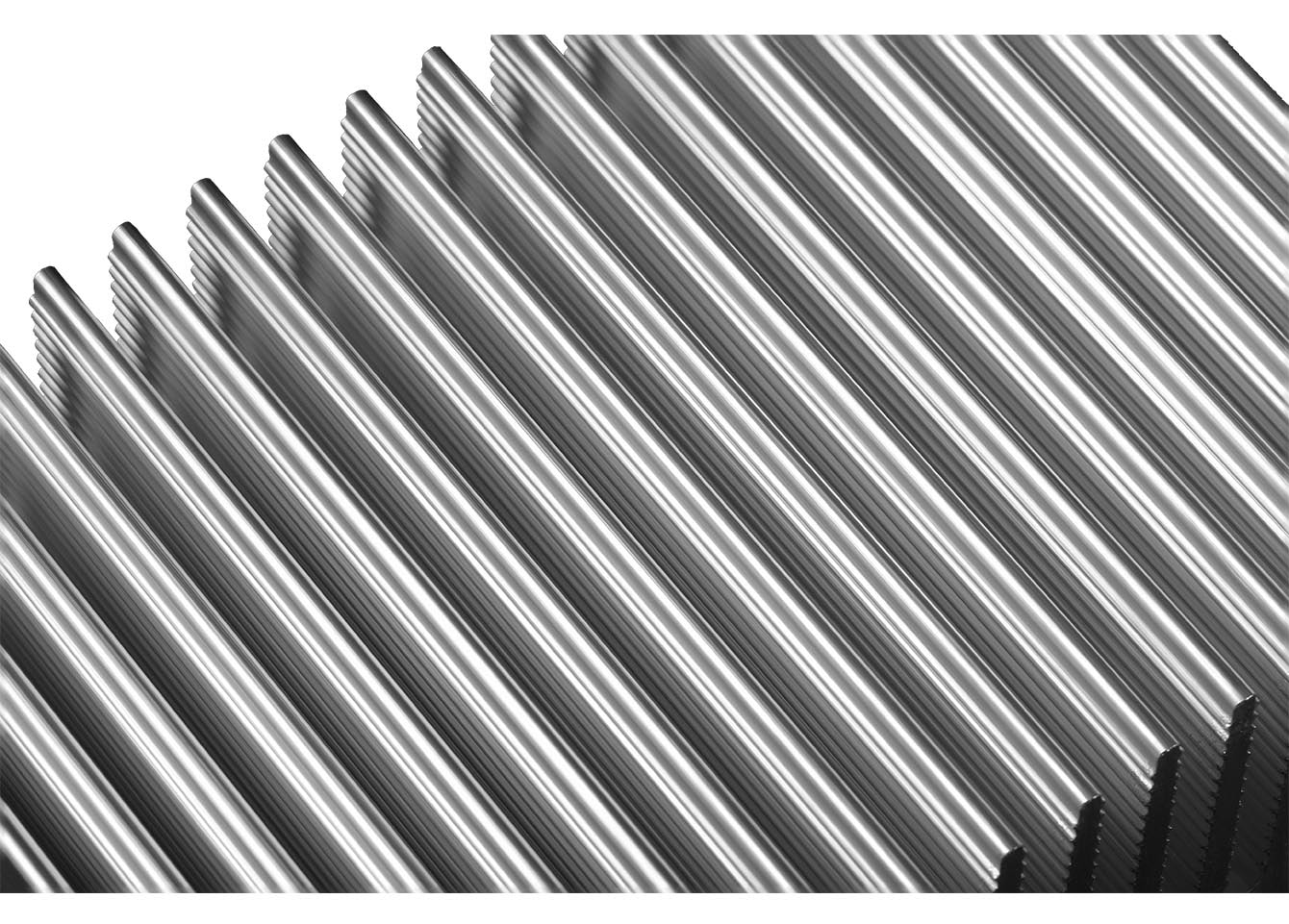

The principle of extruded heatsink

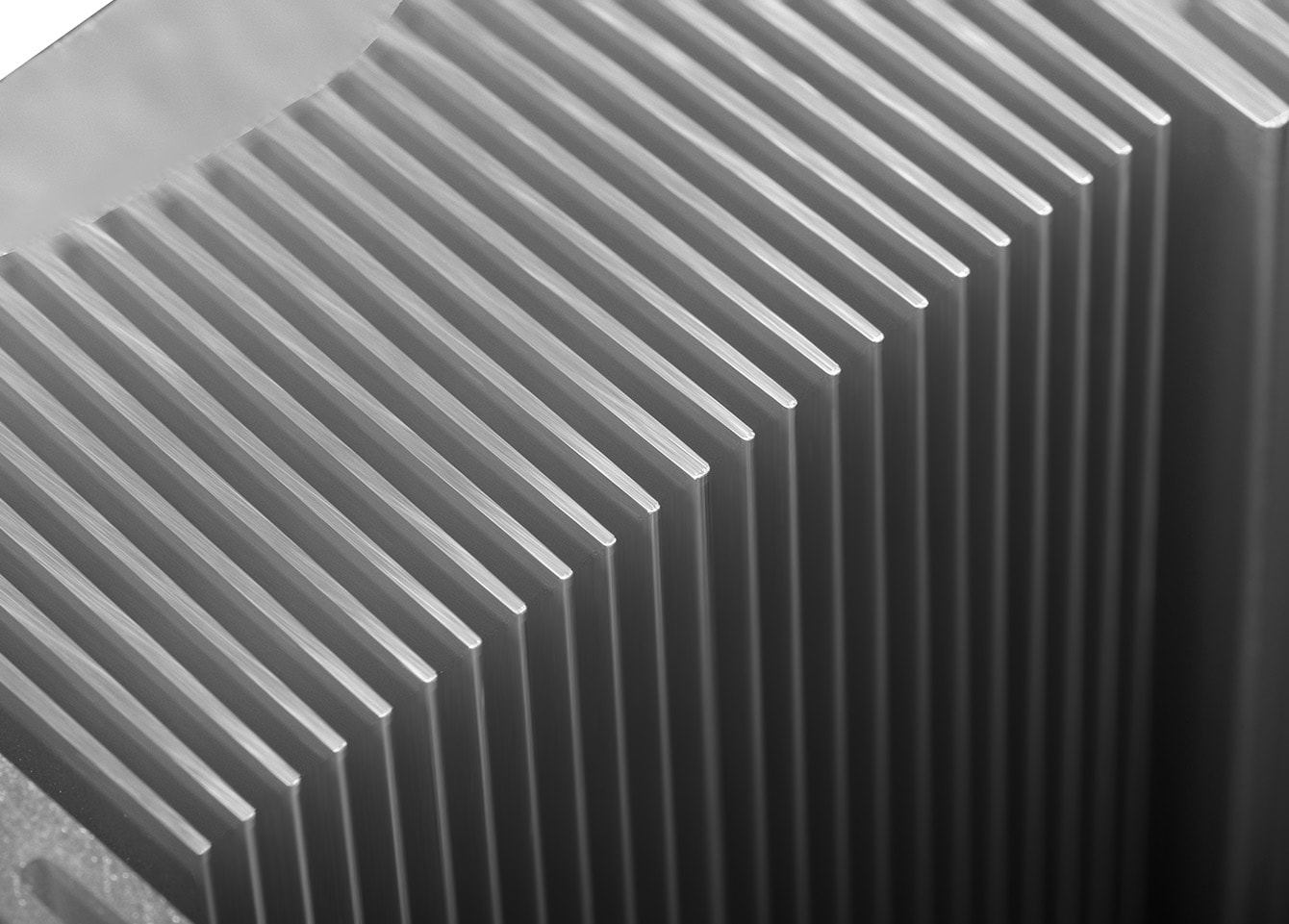

Extruded heatsinks efficiently dissipate heat generated by electronic components by maximizing surface area while maintaining a lightweight and compact design. Fins and channels on the heatsink's surface increase contact area with surrounding air, enhancing heat transfer through convection. Made of aluminum for its excellent thermal conductivity, the heatsink efficiently conducts heat away from components, preventing overheating.

The extrusion process allows for complex geometries tailored to cooling needs. Custom designs optimize shape and size for maximum heat dissipation while minimizing weight and space requirements. Surface treatments enhance corrosion resistance and aesthetics, ensuring longevity and reliability.

High-quality extruded heatsinks feature precise dimensions, uniform fin spacing, and consistent surface finish for optimal thermal performance. Manufacturers offer standard and custom profiles to accommodate diverse heat dissipation needs, enabling efficient thermal management in electronic devices.

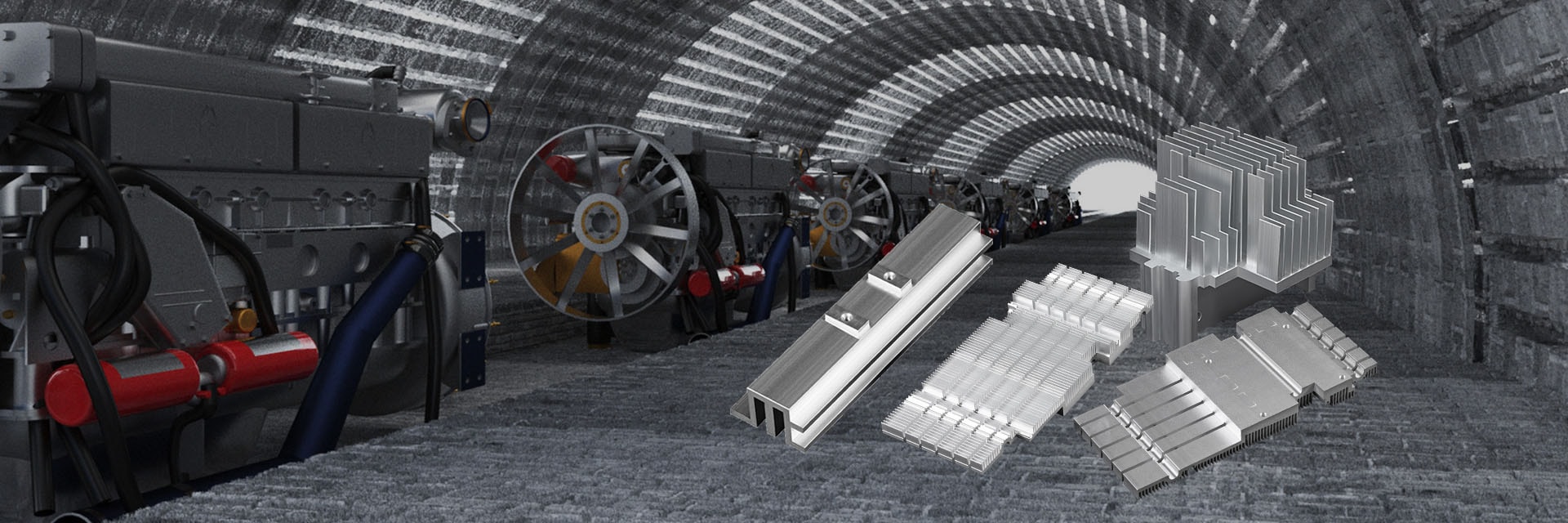

Why Choose Extruded Aluminum Heat Sinks?

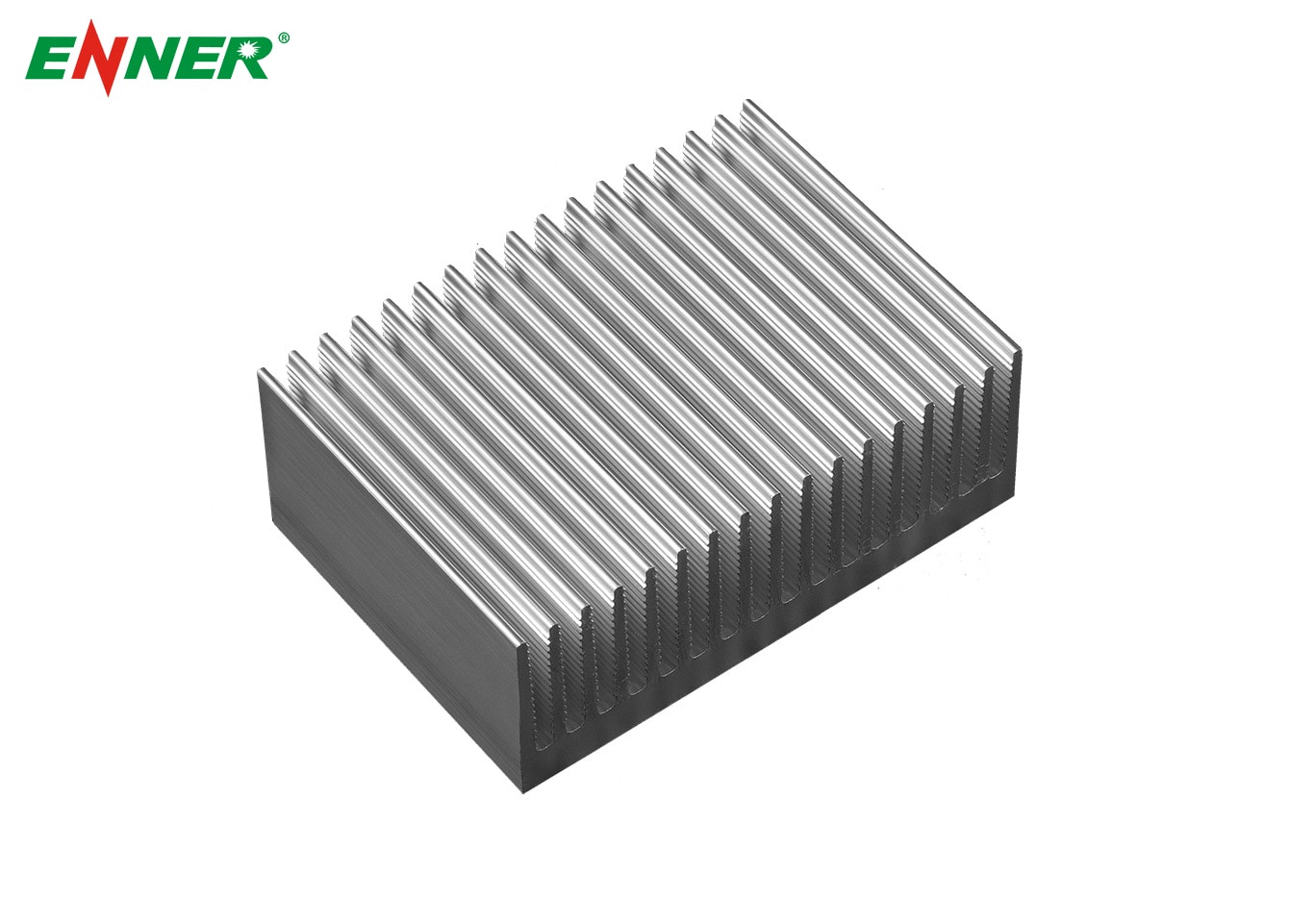

Extruded aluminum heat sinks Extruded aluminum heat sinks offer excellent thermal conductivity, cost-effectiveness, and design flexibility. Made from 6063 aluminum alloys, they efficiently dissipate heat in various electronic systems. The extrusion process allows for scalable production of both standard and custom profiles, making them ideal for industries like power electronics, LED lighting, telecommunications, and industrial automation. With lightweight yet durable construction, they are perfect for compact devices and outdoor installations, while optimized profiles improve airflow and thermal performance. Anodizing and other finishes enhance corrosion resistance for long-lasting use.

Ennergroup: Your Extrusion Heat Sinks Manufacturer

At Ennergroup, we specialize in manufacturing high-quality extruded aluminum heat sinks. Our 6063 aluminum alloys provide superior thermal conductivity for effective heat dissipation. Whether standard or custom profiles, our heat sinks are engineered for lightweight durability, optimized airflow, and corrosion resistance through anodizing and surface finishes. We offer cost-effective, long-lasting solutions for industries requiring reliable thermal management.

-

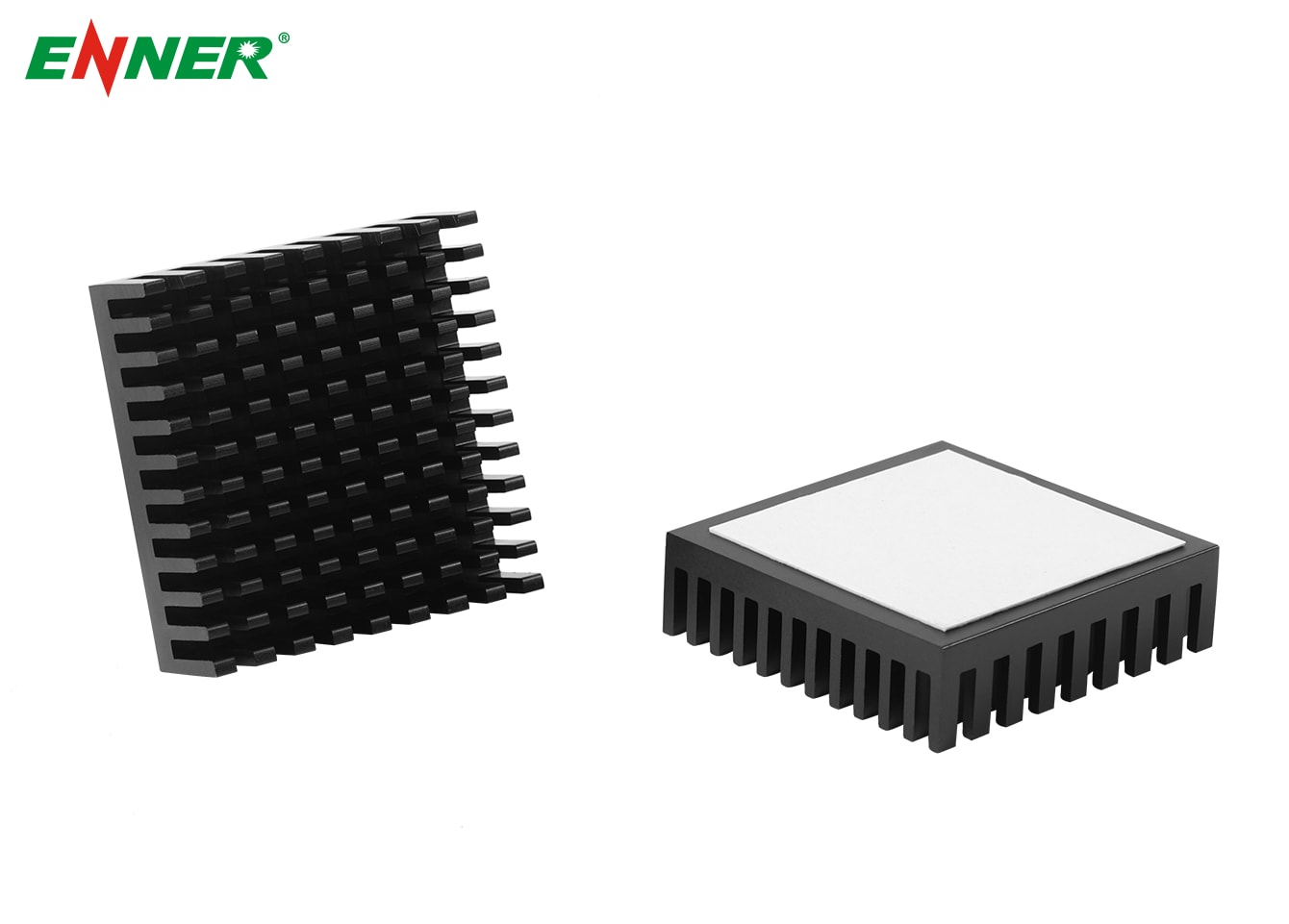

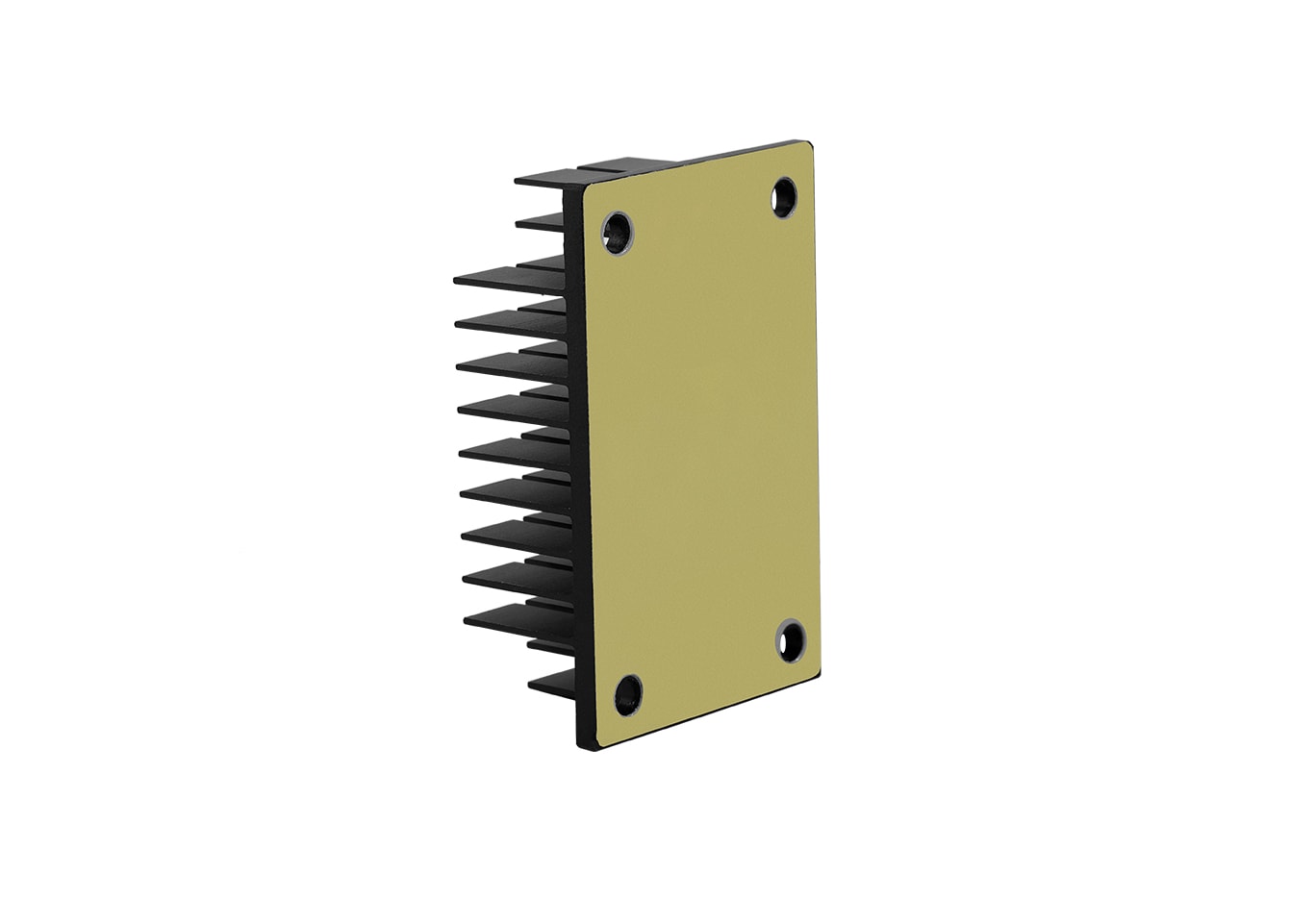

Heatsink With Adhesive Thermal Pad

The Heat Sink with Adhesive Thermal Pad is made of high-quality aluminum with a black anodized finish for efficient heat dissipation. It features an adhesive thermal pad for easy and secure installation, ensuring excellent surface contact. Its vertical fin design enhances airflow, providing effective cooling for electronic components. Ideal for compact electronics needing reliable thermal management.INQUIRE NOW -

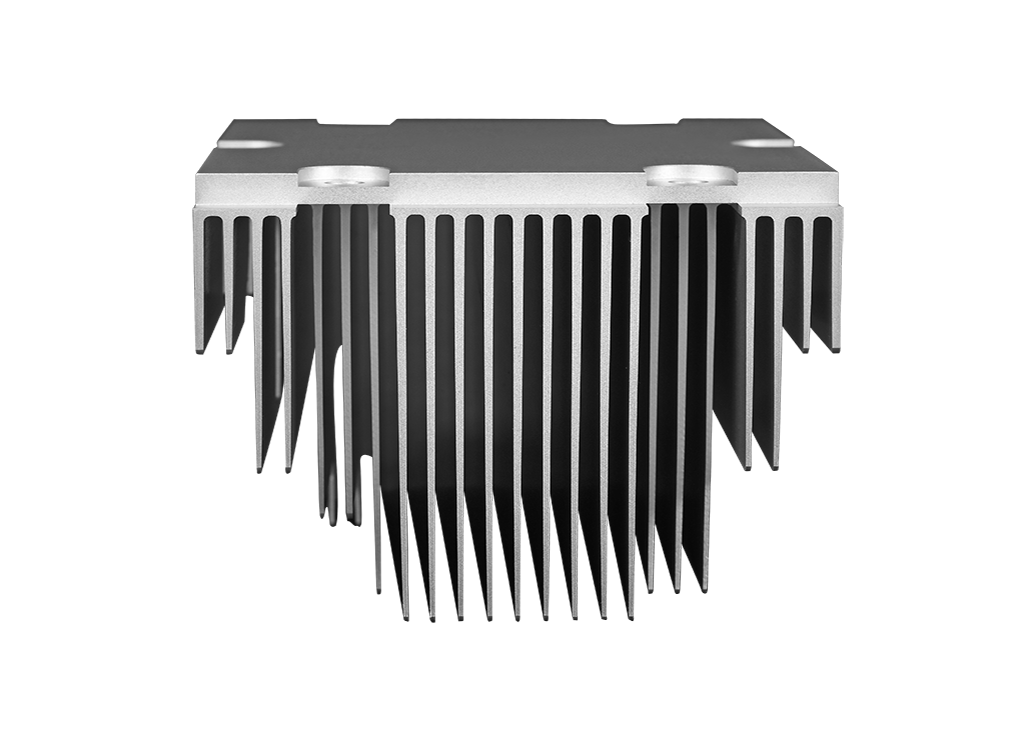

Heatsink With Adhesive Thermal Pad

The Heat Sink with Adhesive Thermal Pad is crafted from high-quality aluminum with a black anodized finish, providing efficient heat dissipation. Featuring a pre-applied adhesive thermal pad, it allows for easy and secure attachment, ensuring optimal contact. The vertical fin design maximizes airflow for improved cooling performance. Perfect for compact electronic devices requiring reliable and convenient thermal management.INQUIRE NOW -

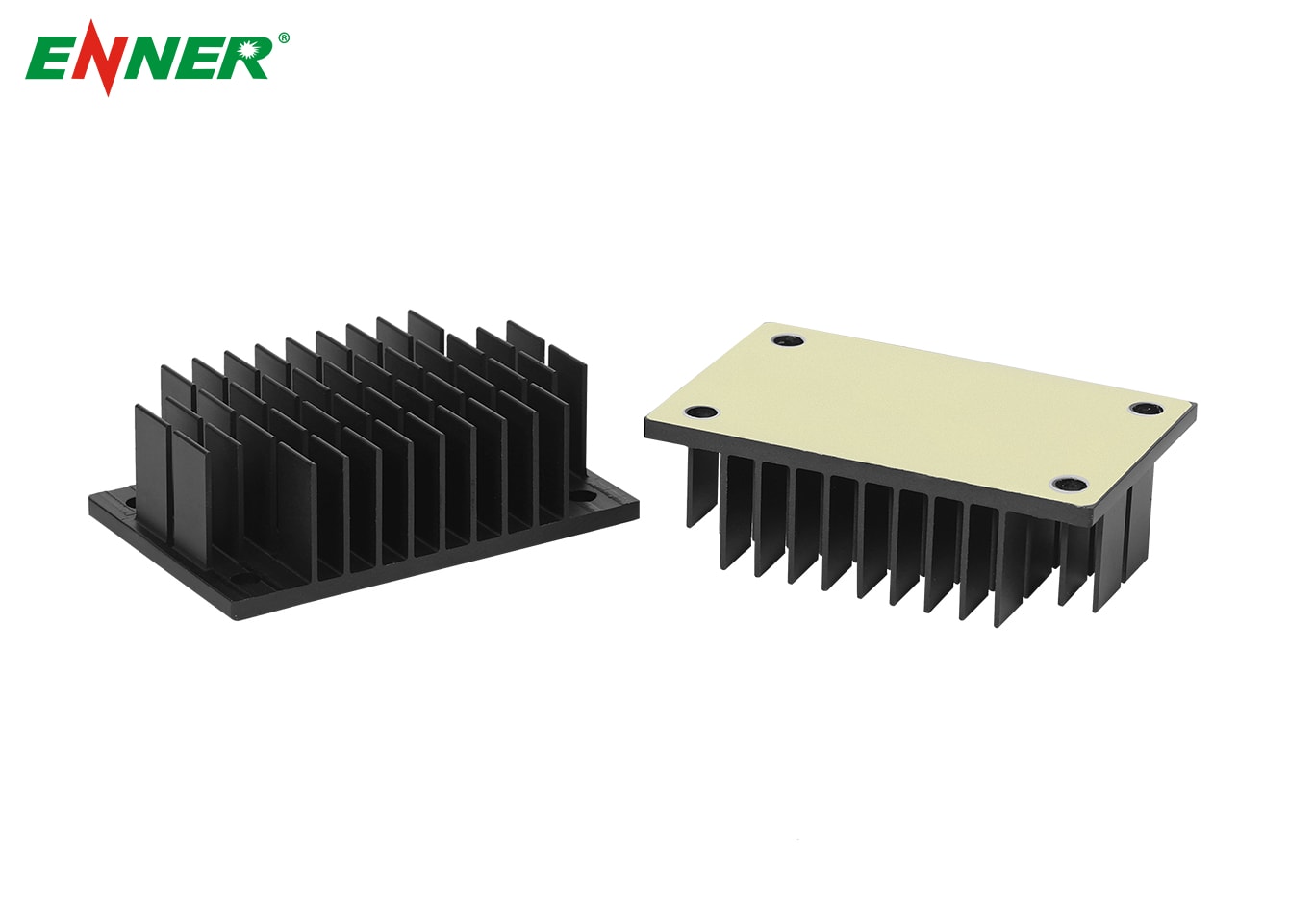

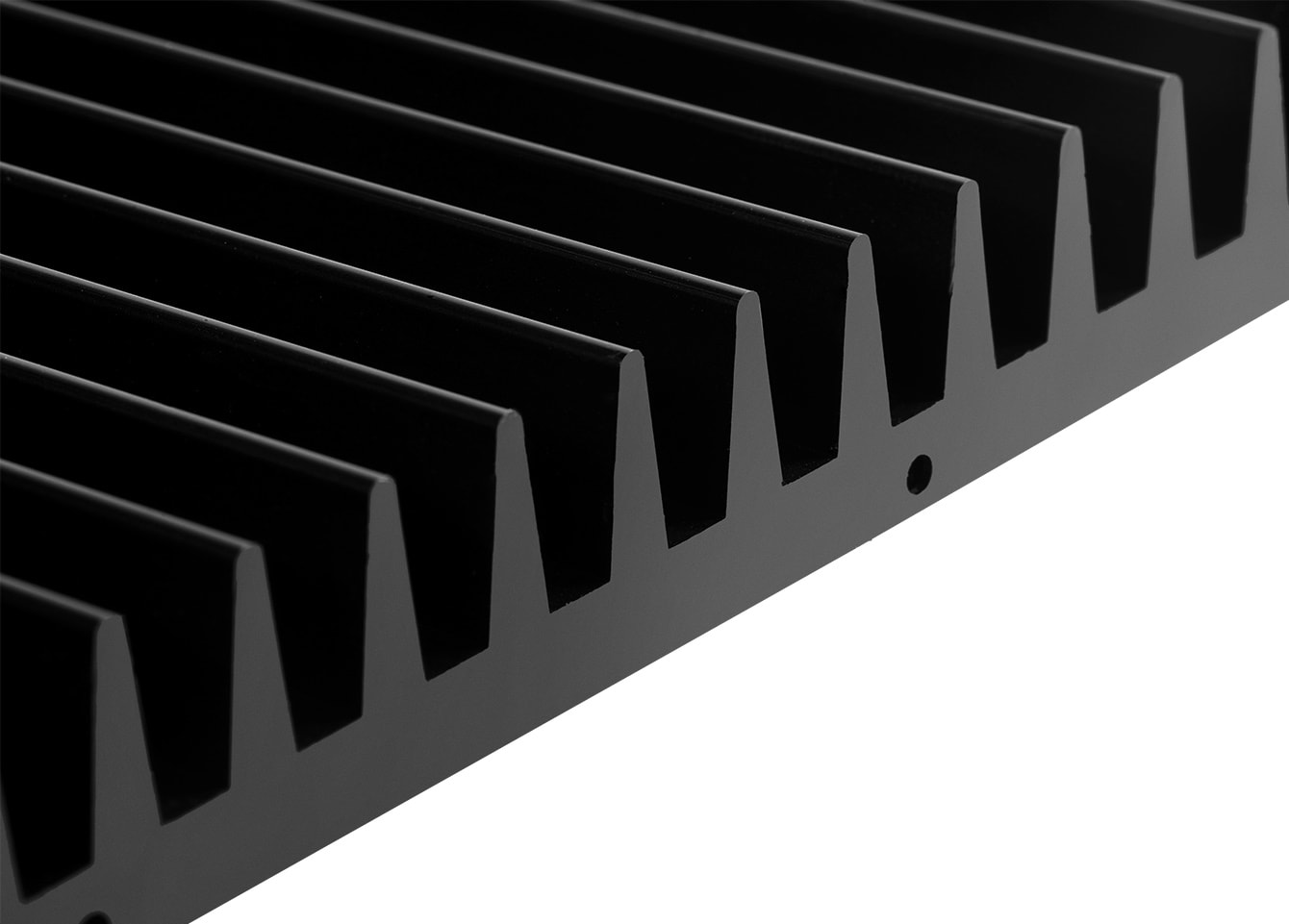

DSH Heatsink

The DSH Heat Sink is a premium aluminum heat sink designed to offer exceptional heat dissipation for large electronic components. Its extensive surface area, coupled with a horizontal fin design, maximizes airflow and ensures efficient cooling performance. The durable black anodized finish enhances both thermal conductivity and corrosion resistance, making it ideal for high-power applications that require reliable heat management. Perfect for industrial and commercial electronic systems that demand robust thermal solutions.INQUIRE NOW -

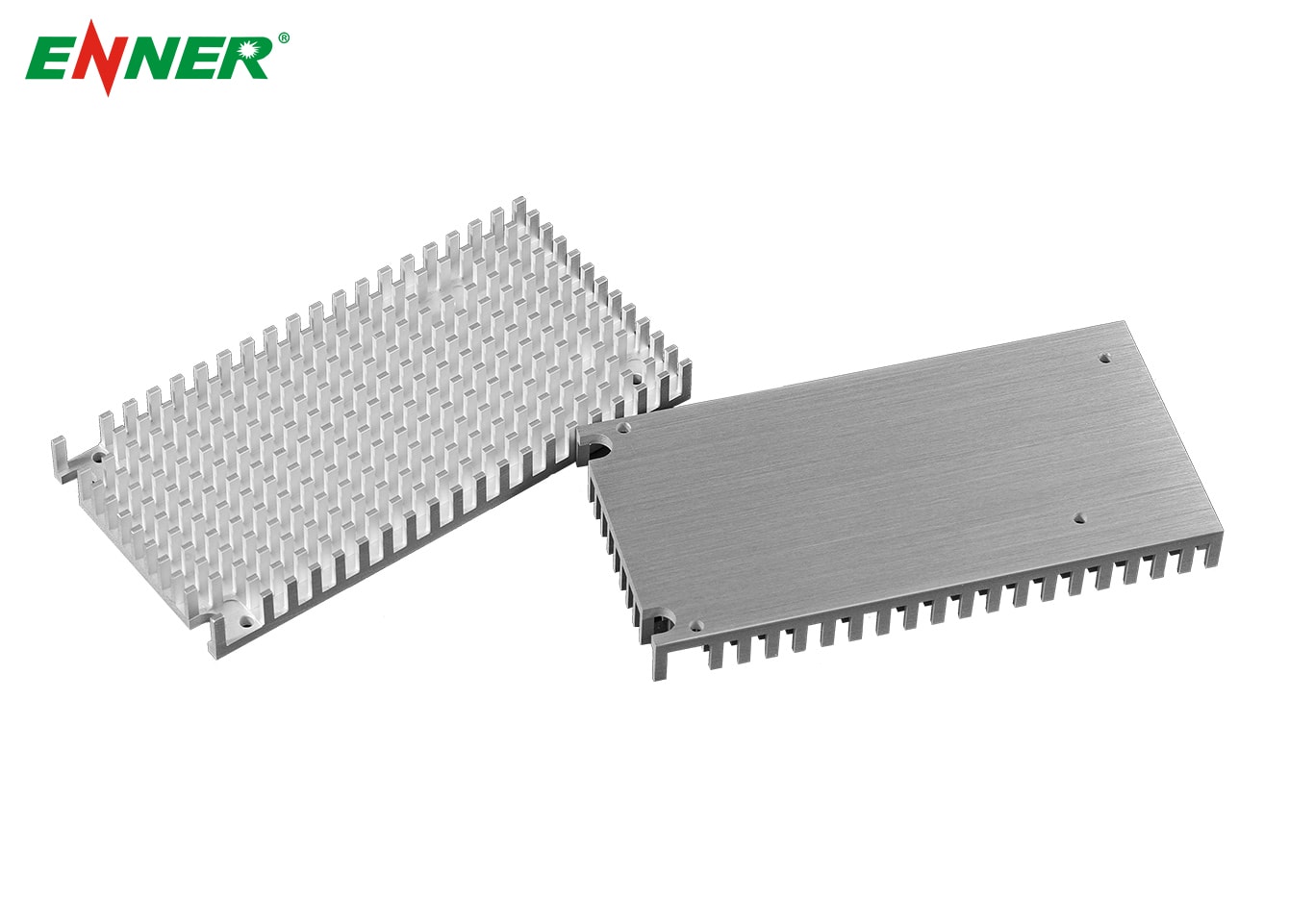

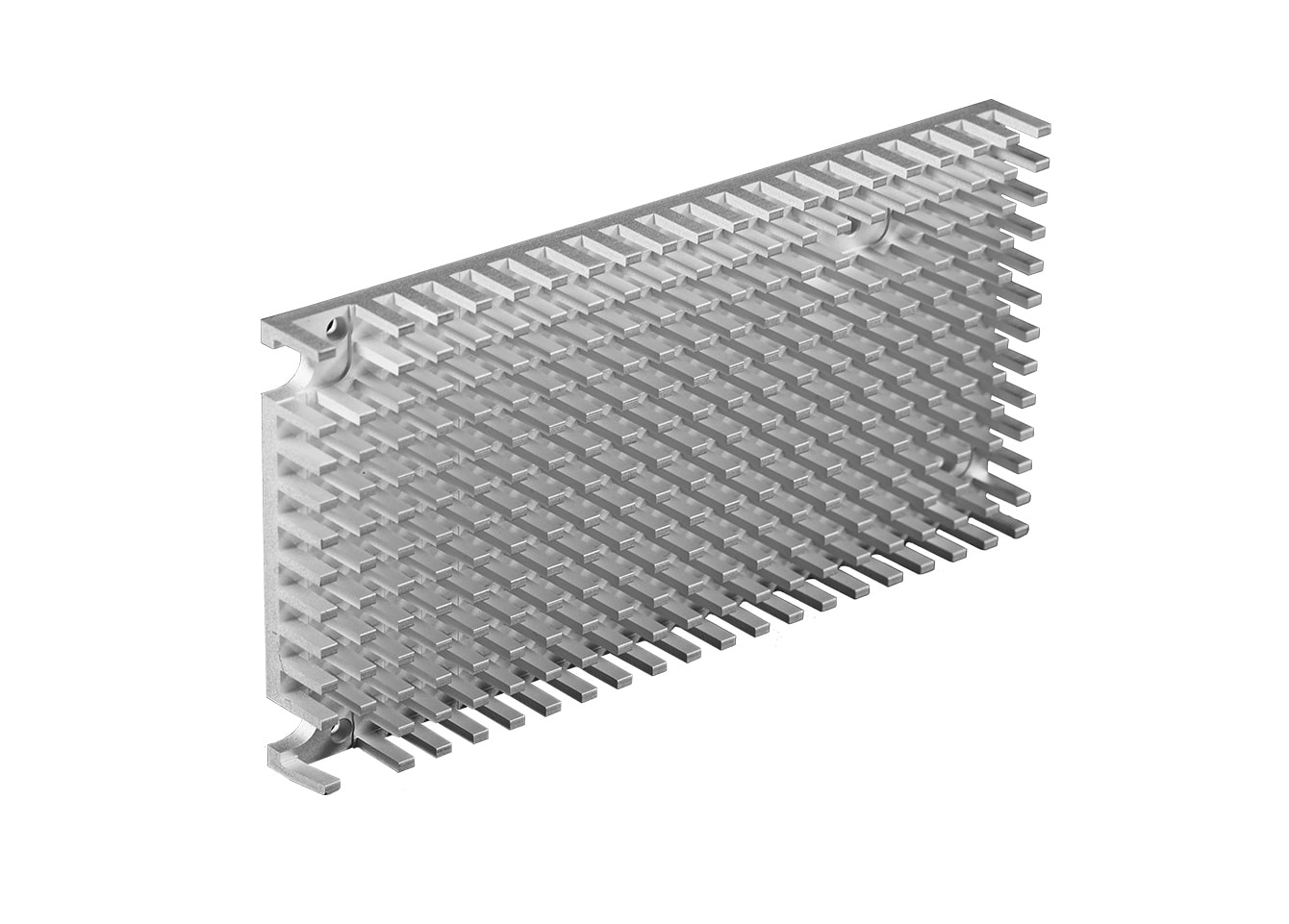

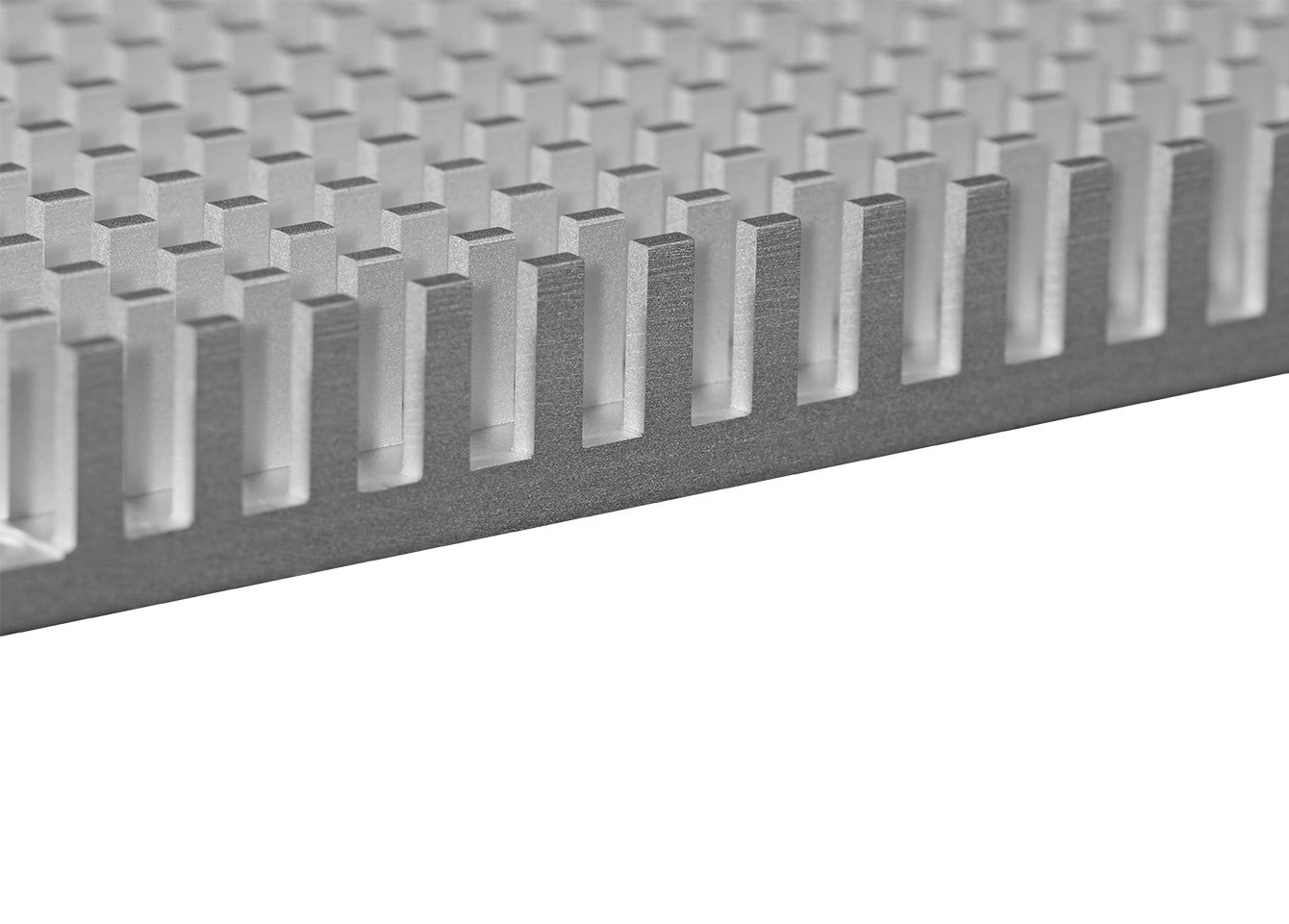

BGA Heatsink

The BGA Heat Sink is made from high-quality aluminum with a natural finish, designed for efficient cooling of Ball Grid Array (BGA) components. Its rectangular shape with precision-engineered pins maximizes surface area for improved airflow and heat dissipation. Lightweight yet robust, this heat sink is perfect for applications requiring effective thermal management to ensure stable performance and extend the lifespan of electronic components. Ideal for use in compact electronics where efficient cooling is essential.INQUIRE NOW -

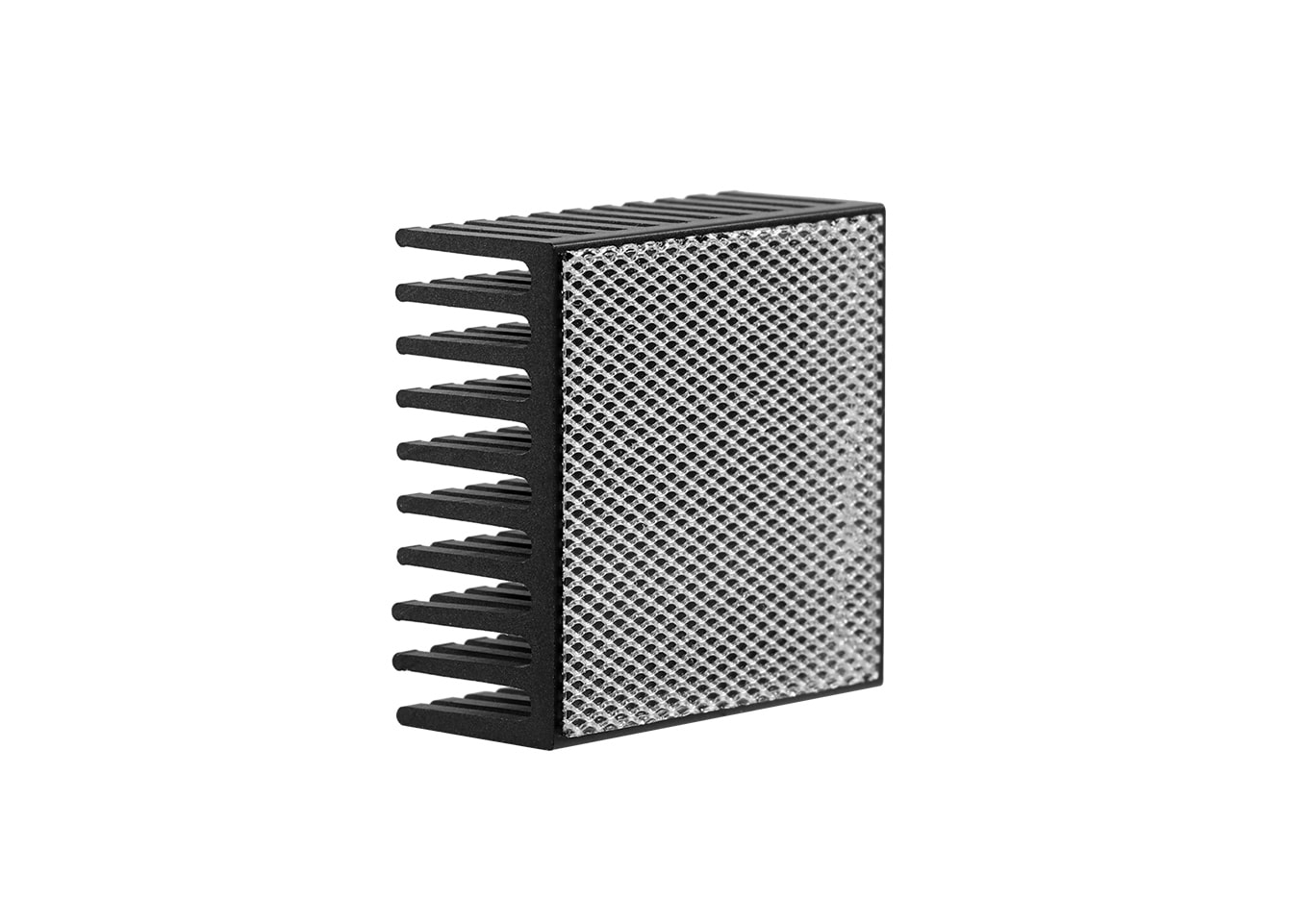

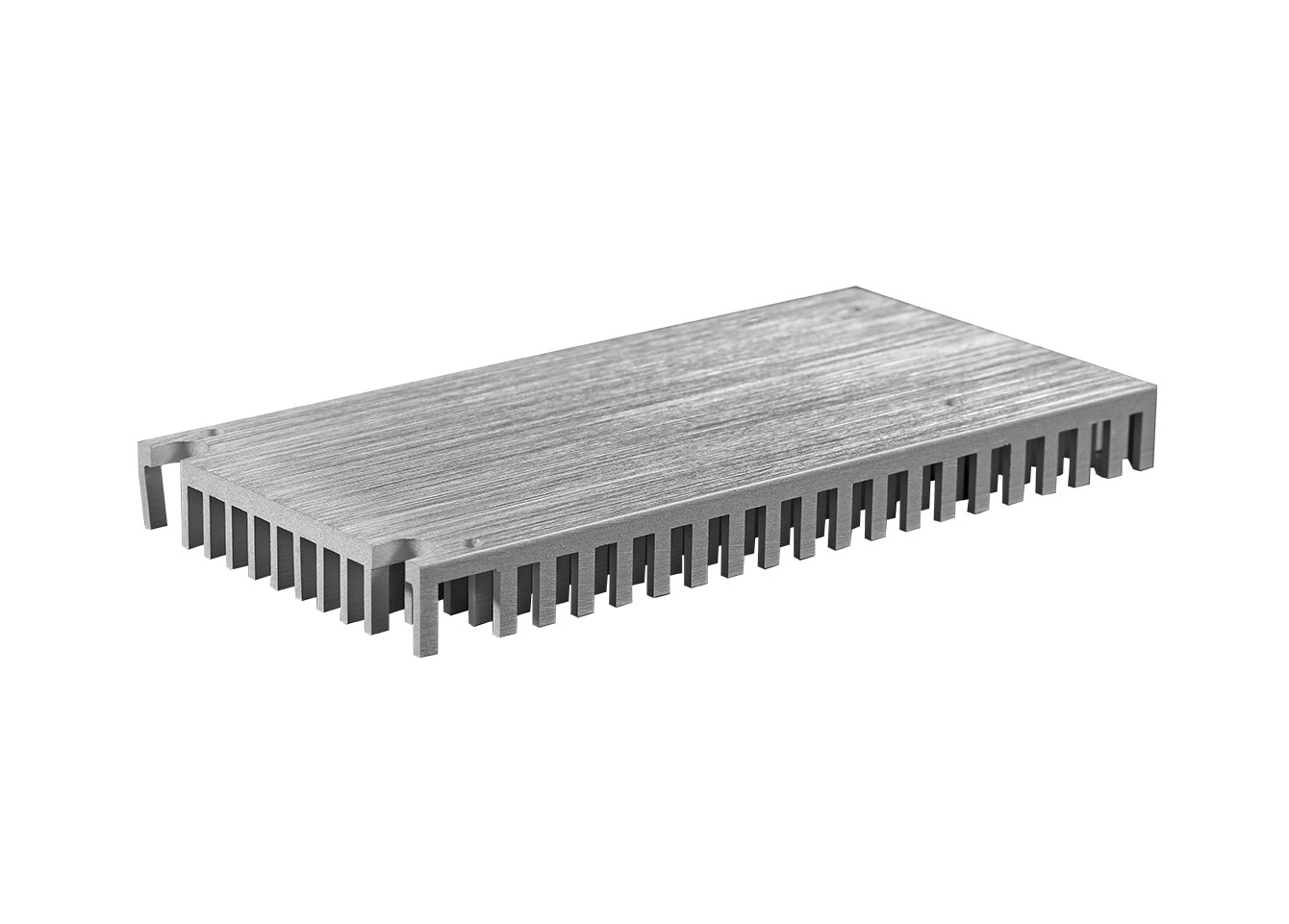

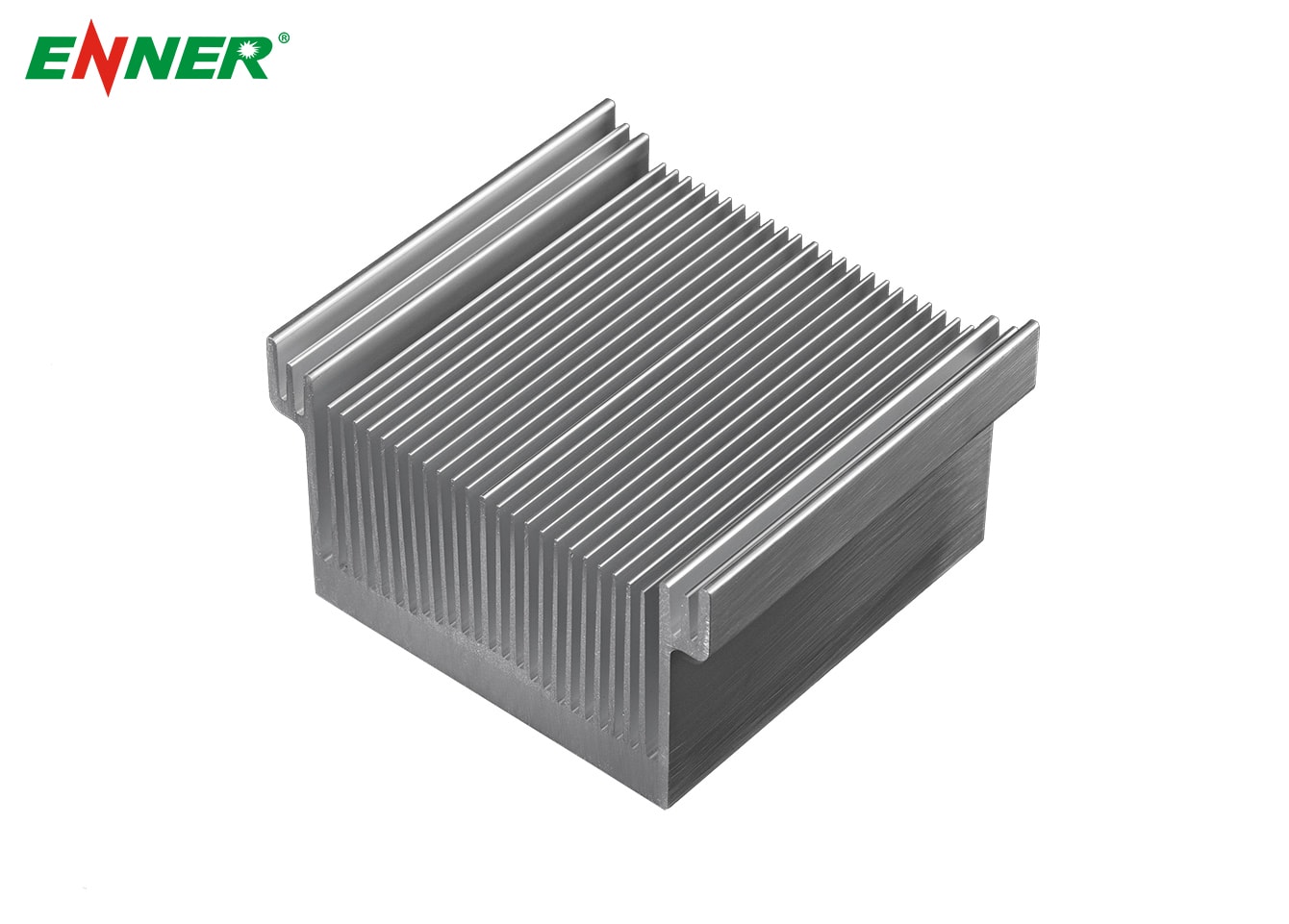

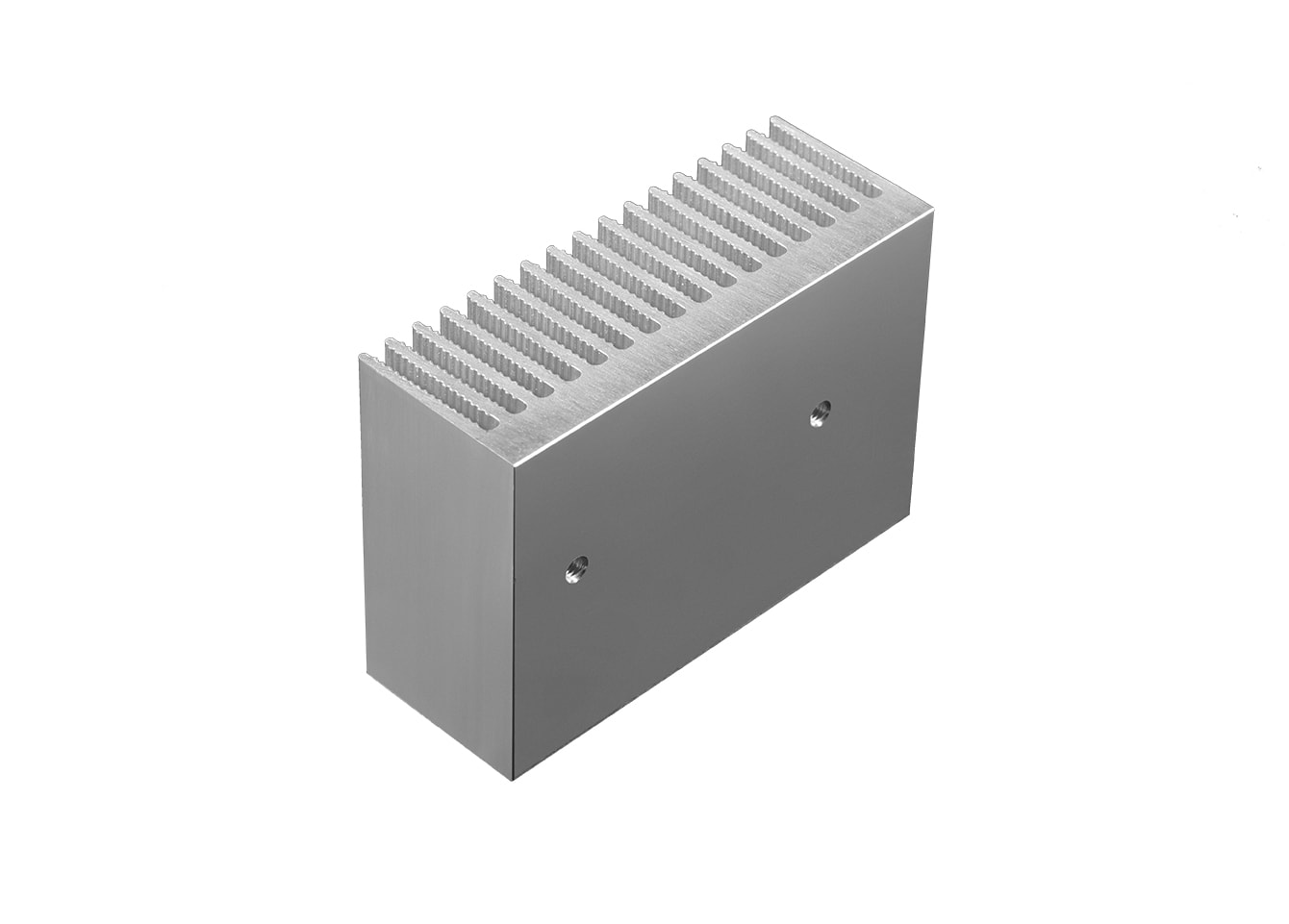

AL 6063 Extrusion Heatsink

The AL 6063 Extrusion Heat Sink is made from high-quality aluminum alloy 6063, designed for superior thermal conductivity and efficient heat dissipation. Its precision-extruded fins maximize surface area, optimizing airflow for effective cooling. The natural finish provides both durability and enhanced thermal performance. Ideal for applications in high-power electronics, this heat sink offers reliable thermal management, ensuring stable operation and extended lifespan for your components. Suitable for industrial and consumer electronics requiring robust and efficient heat dissipation.INQUIRE NOW -

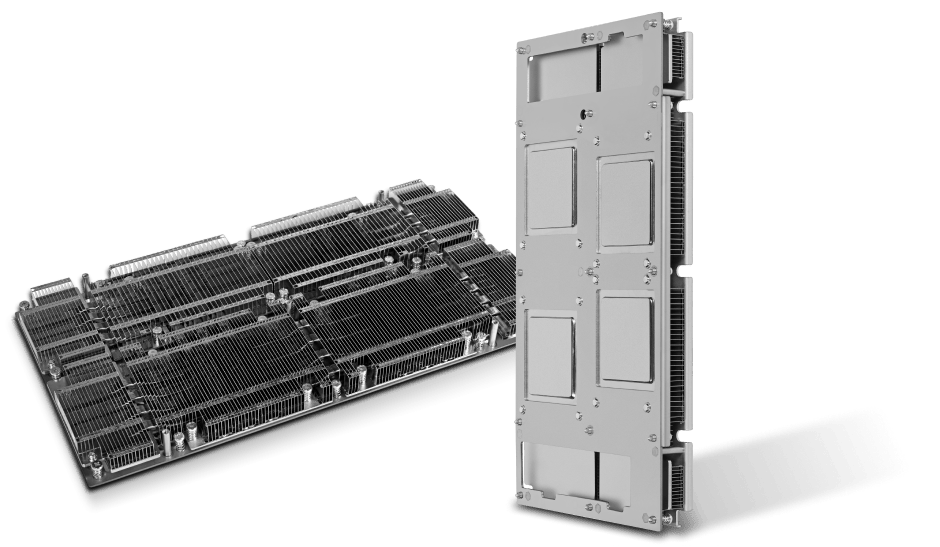

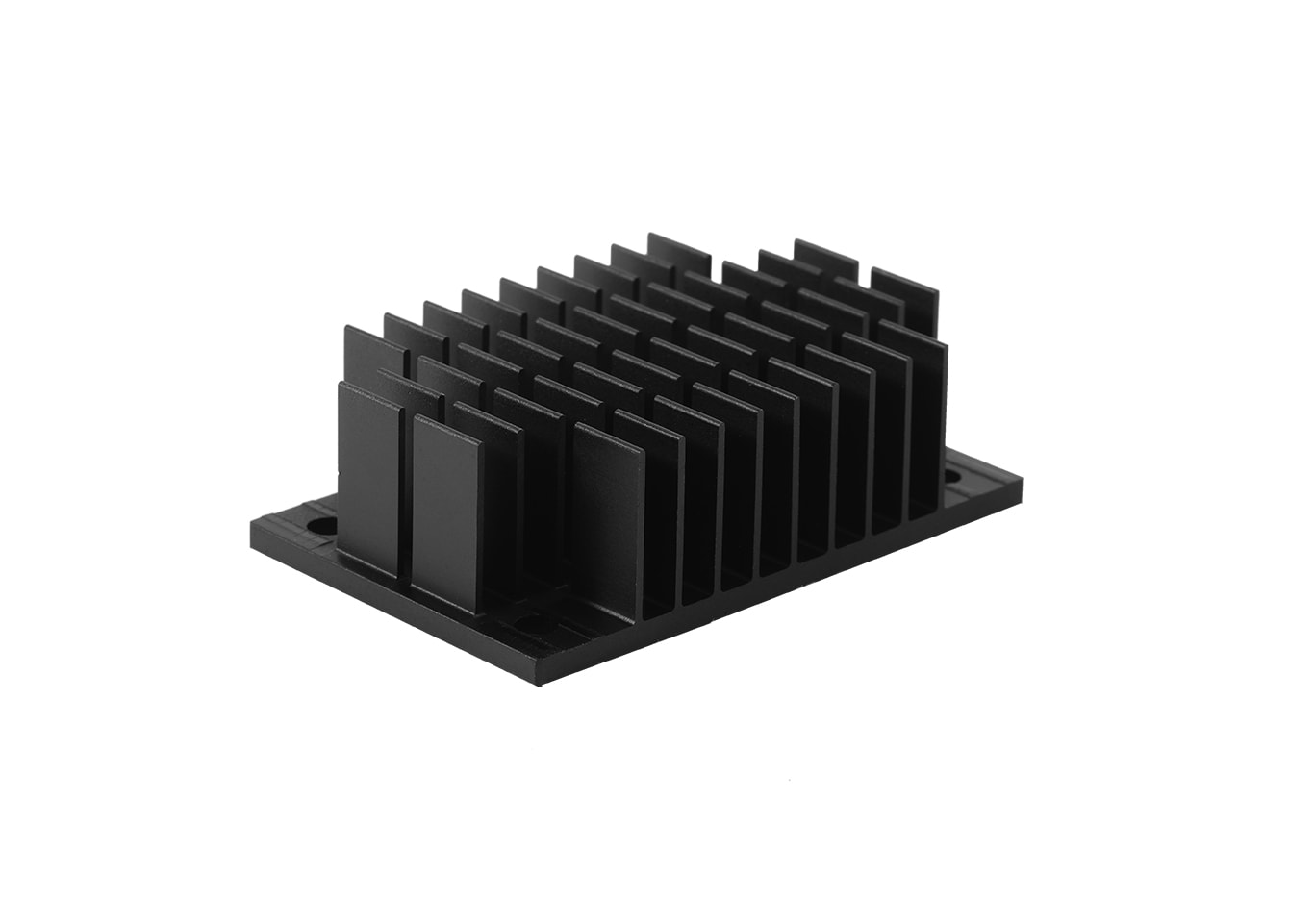

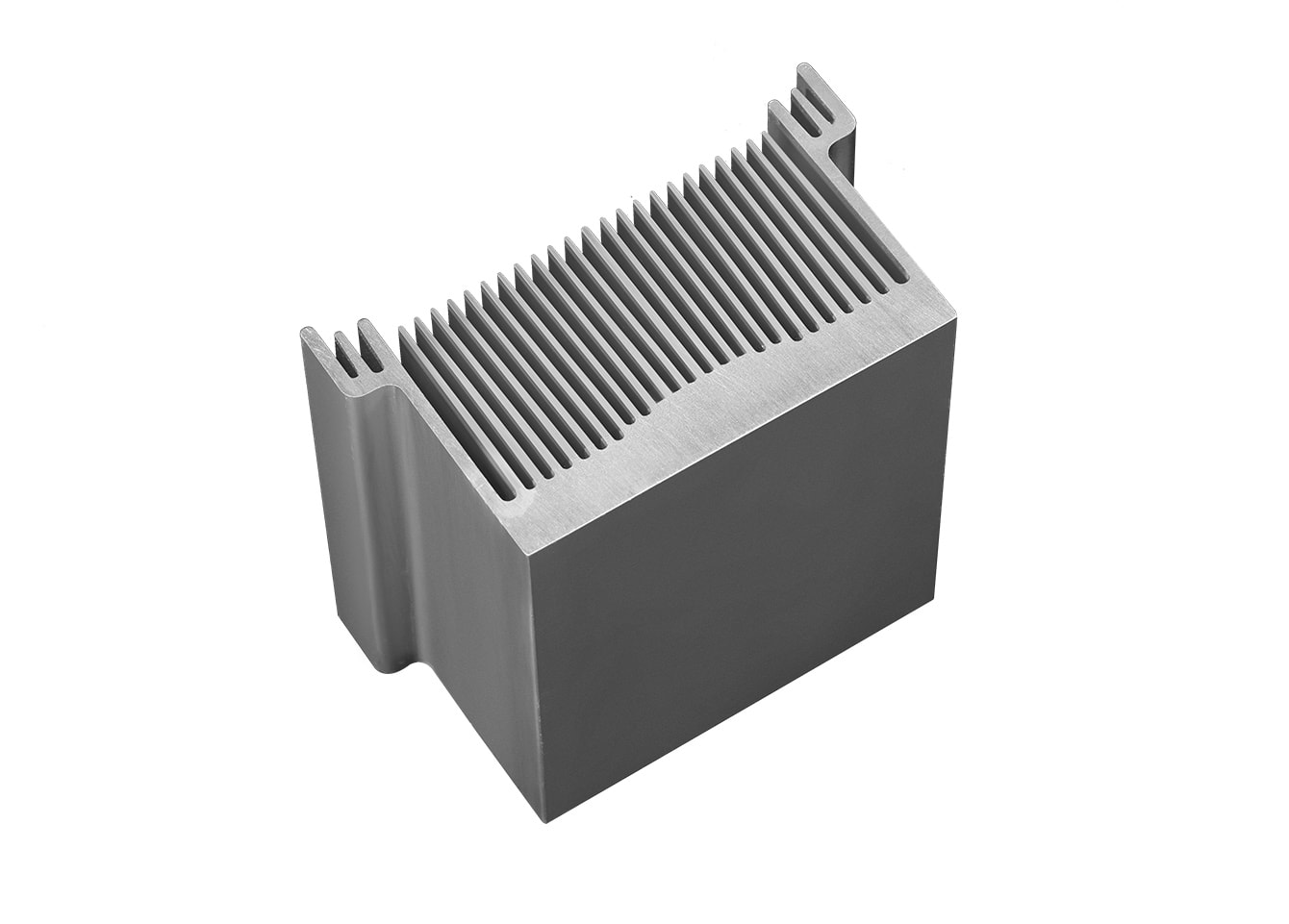

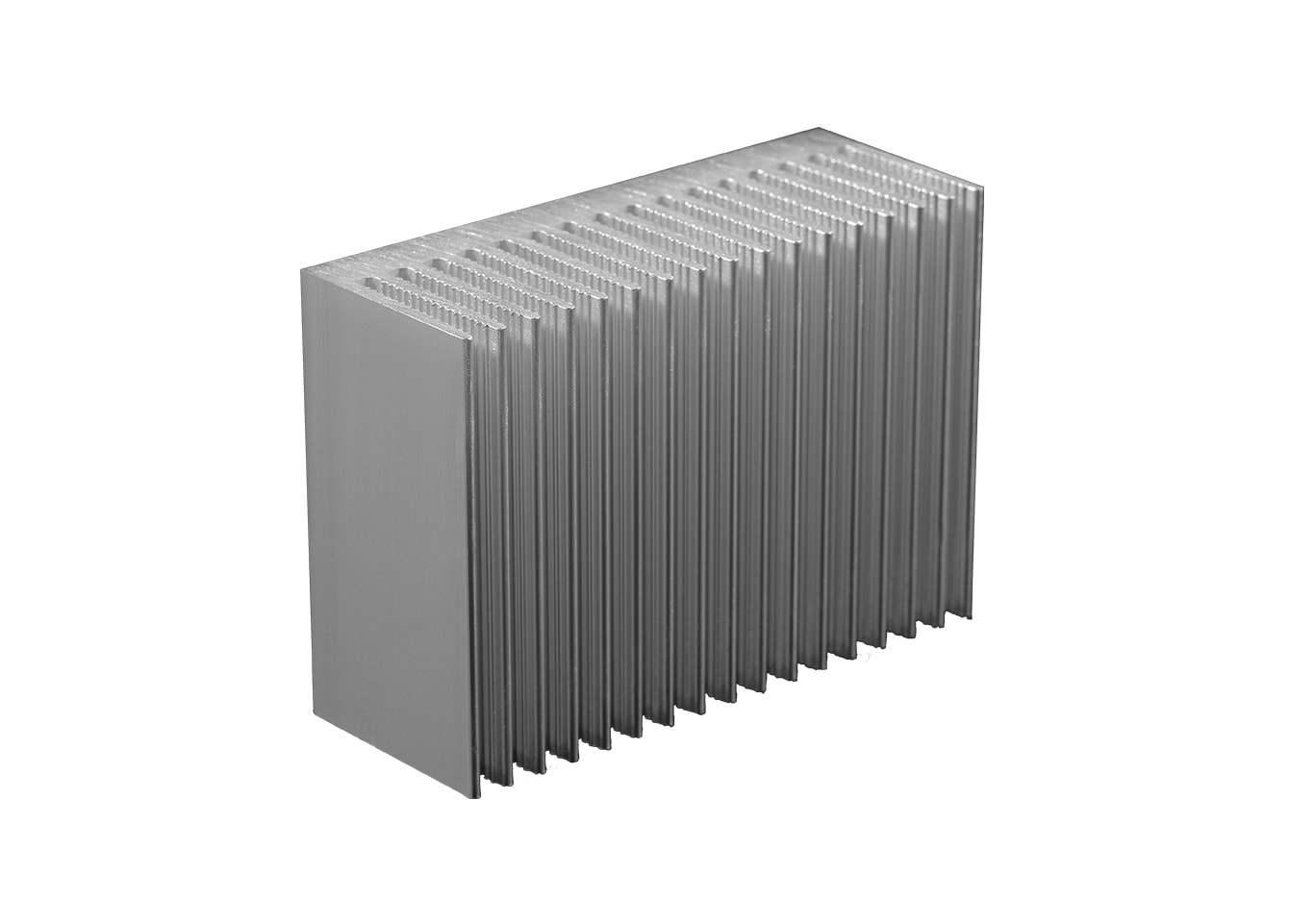

Cms Ecu Heatsink

The CMS ECU Heat Sink is designed for efficient cooling of Engine Control Unit (ECU) components, made from high-quality aluminum with a natural finish. The extruded fin structure maximizes surface area to promote effective airflow and heat dissipation, ensuring reliable thermal management. Its durable and lightweight design helps to maintain the optimal temperature for ECU modules, enhancing performance and extending component lifespan. Ideal for automotive and industrial applications requiring robust and efficient cooling solutions for electronic systems.INQUIRE NOW

Frequently Asked Questions

1. What is an extruded heat sink?

An extruded heat sink is created by pushing aluminum through a precisely shaped die, forming a continuous profile with fins. This process delivers a cost-effective, efficient thermal management solution widely used in electronic and industrial systems.

2. Why is aluminum used in heatsink extrusion?

Aluminum combines excellent thermal conductivity, natural corrosion resistance, and a high strength-to-weight ratio. These properties make it ideal for manufacturing reliable, lightweight extruded heat sinks for diverse thermal applications.

3. Can extruded heat sinks be customized?

Yes. They can be fully customized—including fin geometry, spacing, height, base thickness, and mounting interface—to achieve target thermal resistance and ensure seamless mechanical integration.

4. What surface finishes are available for extruded aluminum heatsinks?

Common finishes include anodizing (improves corrosion resistance and radiant heat emission), powder coating, and chemical polishing. These treatments enhance both performance and appearance.

5. In what industries are extruded heat sinks commonly used?

They are widely used in power electronics, LED lighting, telecommunications, automotive electronics, and industrial automation thanks to their thermal efficiency, scalability, and cost-effectiveness.

Leave a message!

Our professional team will reach you within 24hrs!

Crystal Xi

Crystal Xi

Leave message

Leave message