— Welcome to Enner

— Welcome to Enner

Case1

-

01

Design Introduction

Maximum temperature of heatsink A: 49.51 ℃, temperature rise: 23.51 ℃

Maximum temperature of heatsink B: 49.50 ℃, temperature rise: 23.50 ℃ -

02

Design Introduction

Maximum intemal temperature of heat source:52.44℃

Temprature rise: 26.44℃. -

03

Design Introduction

Vmax 14.96(m/s)

-

04

Design Introduction

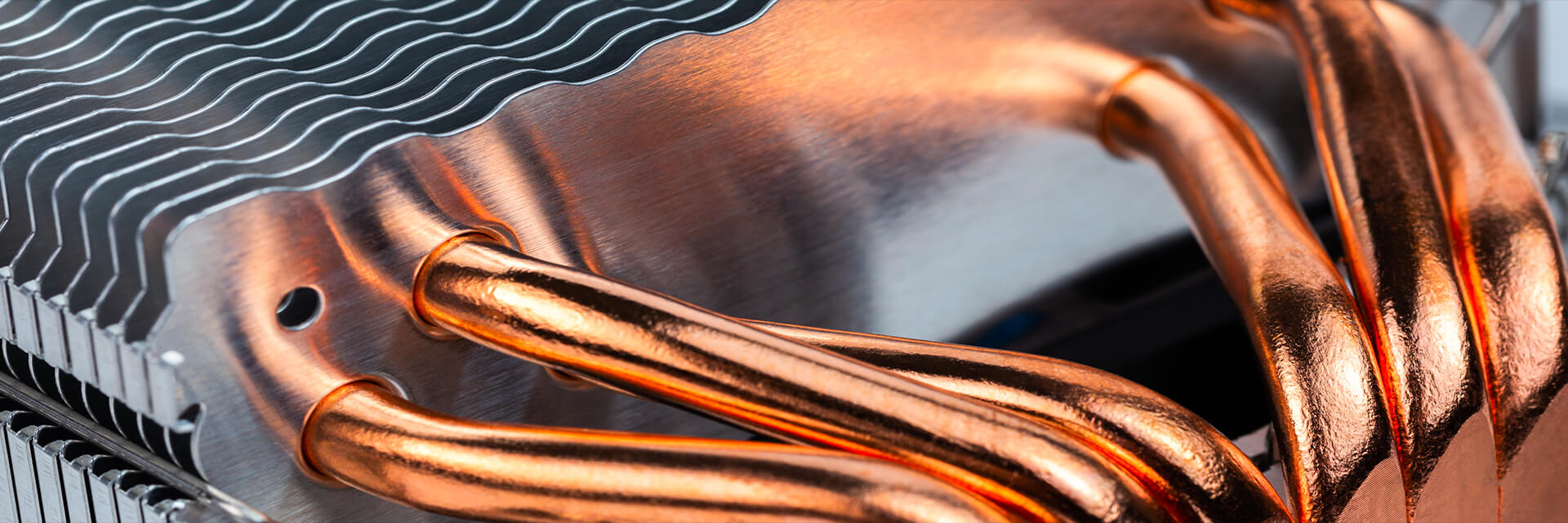

This solution uses heat pipes to dissipate heat, and adds fins to the condensation section of the heat pipe to expand the heat dissipation area, so that chips with high heat flux density can be effectively cooled through conventional forced air convection cooling.

It was confirmed by actual inspection and testing of samples that using a heat pipe cooling solution, the stable temperature was 49°C within 0.3 minutes. -

05

Design Introduction

Vmax 14.96(m/s)

-

01

-

02

-

03

-

04

-

05

Case2

-

01

Design Introduction

Maximum temperature of heatsink A: 39.2 ℃, temperature rise: 13.2 ℃

Maximum temperature of heatsink B: 39.2 ℃, temperature rise: 13.2 ℃ -

02

Design Introduction

Maximum internal temperature of heat source: 41.7℃

Temperature rise: 26.44℃ -

03

Design Introduction

Vmax 8.75(m/s)

-

04

Design Introduction

This solution uses a VC vapor chamber for heat dissipation, and adds fins to the condensation section of the heat pipe to expand the heat dissipation area, so that chips with high heat flux density can be effectively cooled through conventional forced air convection cooling.

It has been confirmed by actual inspection and testing of samples that using a heat pipe cooling solution, the stable temperature is 40°C within 0.3 minutes. -

05

Design Introduction

Vmax 8.75(m/s)

— Welcome to Enner

Analysis of Test Results

According to above test results, given the same heat dissipation demand, different structural designs lead to different performances.

Case 1 Heat Pipe Design: can not meet customer's heat dissipation demand.

Case 2 Vapor Chamber Soaking Plate Design: can meet customer's heat dissipation demand.

Data Analysis of Heat Pipe Design Test and Vapor Chamber Design Test

- Case1 (Heat Pipe)

- Case2 (Vapor Chamber)

This project has been designed and developed based on ENNER analysis report case2 and is currently in mass production

Crystal Xi

Crystal Xi

Leave message

Leave message